Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

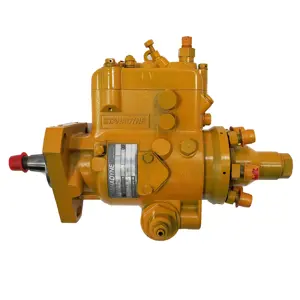

Manual for CAT Plunger pump 3545

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

CAT Plunger pump 3545

Create an account to install this asset package.

Maintenance Plans for CAT Plunger pump Model 3545

Integrate maintenance plans directly into your work orders in MaintainX.

500 Hourly / 3 Monthly Plunger Pump Lubrication

LUBRICATION

Fill crankcase with special CAT PUMP oil per pump specifications (4.2 Qts. - 4.0 L)

Check if pump is running without oil in crankcase

Change initial fill after 50 hours running period

Thereafter, change oil every 3 months or 500 hour intervals

Oiler adjustment is vertical to start feed, horizontal to stop feed, dial to adjust _x001e_flow rate

Additional lubrication may be required with increased hours of operation and temperature

PUMP ROTATION

Pump was designed for forward rotation to allow optimum lubrication of the crosshead area

1 Weekly Plunger Pump Check

Check Belts

Check Pulley

Check Plumbing

3000 Hourly Plunger Pump Check

Each system's maintenance cycle will be exclusive. If system performance decreases, check immediately. If no wear at 1500 hours, check again at 2000 hours and each 500 hours until wear is observed. Valves typically require changing every other seal change. Duty cycle, temperature, quality of pumped liquid and inlet feed conditions all effect the life of pump wear parts and service cycle.

Valve Change

Service the regulator/unloader at each seal servicing

Check all system accessories and connections before resuming operation

Sign off on the plunger pump check

1 Daily Plunger Pump Check

Clean Filters. Use adequate mesh size for liquid and pump specifications.

Check Oil Level/Quality

Check for Oil Leaks

Check for Water Leaks

1500 Hourly Plunger Pump Check

Each system's maintenance cycle will be exclusive. If system performance decreases, check immediately. If no wear at 1500 hours, check again at 2000 hours and each 500 hours until wear is observed. Valves typically require changing every other seal change. Duty cycle, temperature, quality of pumped liquid and inlet feed conditions all effect the life of pump wear parts and service cycle.

Remember to service the regulator/unloader at each seal servicing and check all system accessories and connections before resuming operation.

Seal Change

Accessories Check

Enter the current hours of operation

Sign off on the plunger pump check

Parts for CAT Plunger pump 3545

Access the parts list for your equipment in MaintainX.

Inlet Manifold Screws M12 Allen

33048

Discharge Manifold Screws M10 Allen

33047

Valve Plug Screws M12 Allen

33048

Rear Cover/Bearing Cover Screws M13 Hex

25324

Connecting Rod Screws M17 Hex

25083

Inlet Manifold Screws M12 Allen

33048

Discharge Manifold Screws M10 Allen

33047

Valve Plug Screws M12 Allen

33048

Rear Cover/Bearing Cover Screws M13 Hex

25324

Connecting Rod Screws M17 Hex

25083

Inlet Manifold Screws M12 Allen

33048

Discharge Manifold Screws M10 Allen

33047

Valve Plug Screws M12 Allen

33048

Rear Cover/Bearing Cover Screws M13 Hex

25324

Connecting Rod Screws M17 Hex

25083

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX