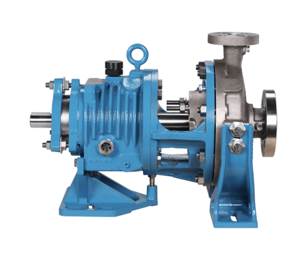

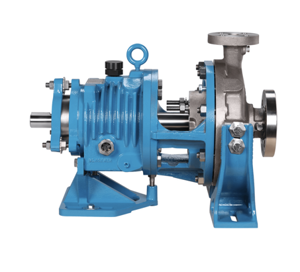

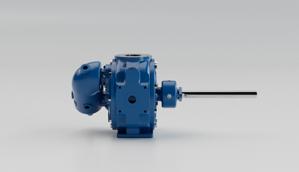

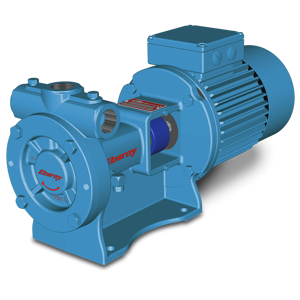

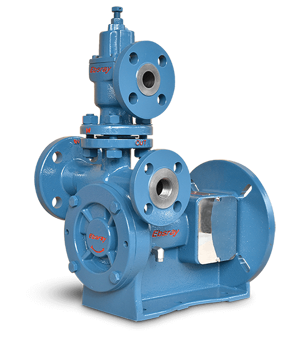

The Blackmer Sliding Vane Pump XF1PC is a reliable and efficient pump designed for transferring various liquids. Known for its robust construction and ease of maintenance, this model ensures optimal performance in industrial applications, making it a preferred choice for operators seeking durability and efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Sliding Vane Pump XF1PC

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Sliding Vane Pump XF1PC

Create an account to install this asset package.

Maintenance Plans for Blackmer Sliding Vane Pump Model XF1PC

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Pump Bearing Lubrication

NOTICE: To avoid possible entanglement in moving parts do not lubricate pump bearings, gear reducer or any other parts while the pump is running

NOTICE: If pumps are repainted in the field, ensure that the grease relief fittings (76A) are functioning properly after painting. Do NOT paint them closed. Remove any excess paint from the fittings

Grease relief fittings removed from the bearing covers

Grease applied slowly with a hand gun until it begins to escape from the grease relief fitting port

Grease relief fittings replaced

DO NOT overgrease pump bearings. While it is normal for some grease to escape from the grease tell-tale hole after lubrication, excessive grease on pumps equipped with mechanical seals can cause seal failure

Strainers cleaned regularly to avoid pump starvation

Schedule for strainer cleaning depending on the application and conditions

Sign off on the pump bearing lubrication

Pump Overhaul

NOTICE: Follow all hazard warnings and instructions provided in the “maintenance” section of this manual

NOTE: The numbers in parentheses following individual parts indicate reference numbers on the Pump Parts List

Drain and relieve pressure from the pump and system as required

Loosen the coupling and remove the shaft key

Remove the four mounting screws and remove the entire pump assembly from the bracket mount

Remove the bearing cover capscrews, the bearing cover and gasket. Discard the bearing cover gasket

Remove the locknut and lockwasher from the shaft end protruding through the head

Bend up the engaged lockwasher tang and rotate the locknut counterclockwise to remove it from the shaft

Slide the lockwasher off the shaft. Inspect the lockwasher for damage and replace as required

Vane Replacement

NOTICE: Maintenance shall be performed by qualified technicians only. Follow the appropriate procedures and warnings as presented in manual

NOTE: The numbers in parentheses following individual parts indicate reference numbers on the Pump Parts List

Drain and relieve pressure from the pump and system as required

If the pump shaft is protruding through the cylinder, remove the head assembly from the pump. If the pump shaft is protruding through the head, remove the entire pump from the mounting bracket, then remove the head assembly from the pump

Turn the shaft by hand until a vane comes to the top position of the rotor. Remove the vane

Install a new vane, ensuring that the relief groove is facing toward the direction of rotation

Repeat steps 3 and 4 until all vanes have been replaced

Reassemble the pump

Sign off on the vane replacement

Parts for Blackmer Sliding Vane Pump XF1PC

Access the parts list for your equipment in MaintainX.

Bracket Mounting Screws

920090

Rotor & Shaft Assembly, Six Vane

262910

Capscrews – Bearing Cover

920080

Spring – R/V (66 - 125 psi) (Std.)

472905

Guard

804120

Bracket Mounting Screws

920090

Rotor & Shaft Assembly, Six Vane

262910

Capscrews – Bearing Cover

920080

Spring – R/V (66 - 125 psi) (Std.)

472905

Guard

804120

Bracket Mounting Screws

920090

Rotor & Shaft Assembly, Six Vane

262910

Capscrews – Bearing Cover

920080

Spring – R/V (66 - 125 psi) (Std.)

472905

Guard

804120

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX