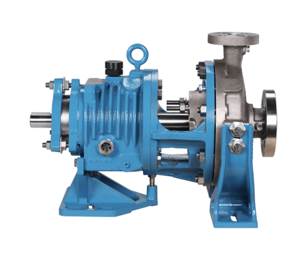

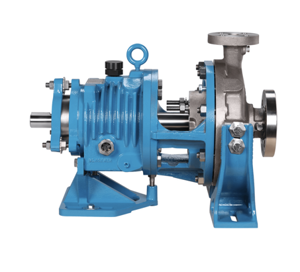

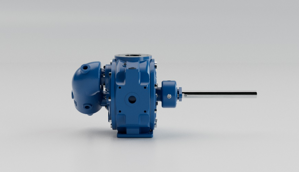

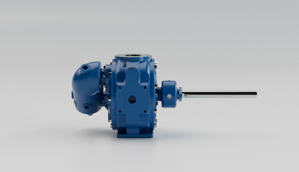

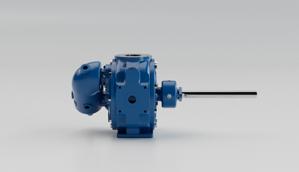

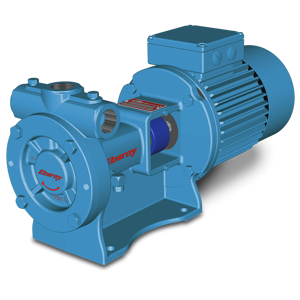

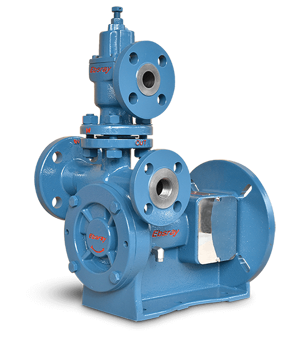

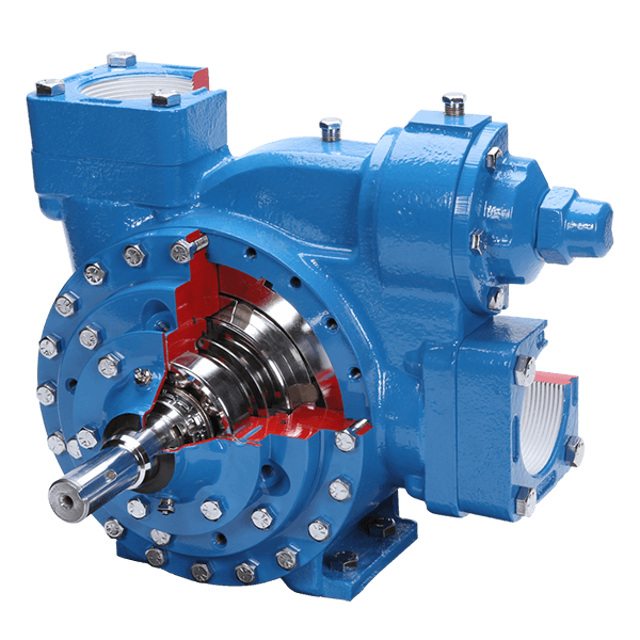

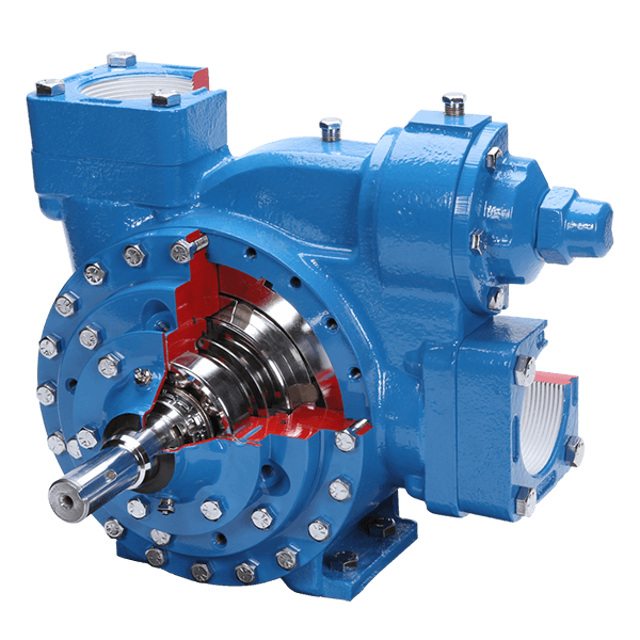

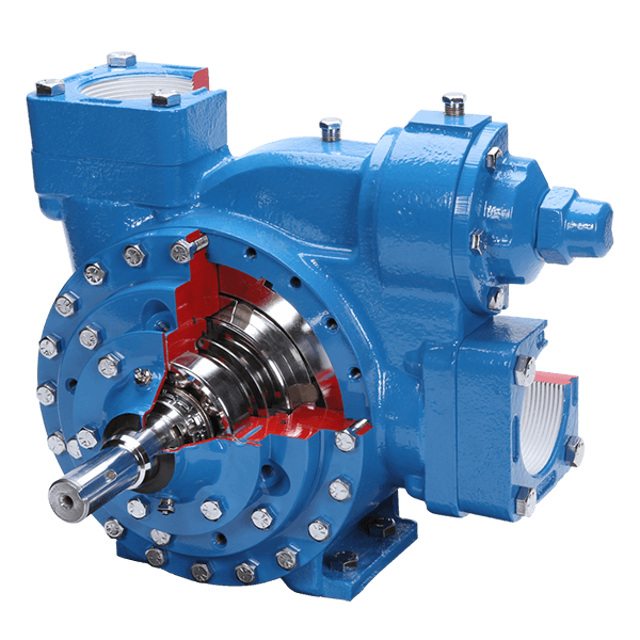

The Blackmer Sliding Vane Pump SGLD2 is a highly efficient and reliable pump designed for transferring various liquids. Known for its robust construction and ease of maintenance, this model is ideal for industrial applications requiring consistent performance and durability. Optimize your operations with the SGLD2's advanced features and proven technology.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Sliding Vane Pump SGLD2

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Sliding Vane Pump SGLD2

Create an account to install this asset package.

Maintenance Plans for Blackmer Sliding Vane Pump Model SGLD2

Integrate maintenance plans directly into your work orders in MaintainX.

Pump Overhaul

Drain and relieve pressure from the pump and system as required

Clean the pump shaft thoroughly, making sure the shaft is free of nicks and burrs

Remove the inboard bearing cover capscrews and slide the inboard bearing cover and gasket off the shaft

Remove the outboard bearing cover capscrews and slide the outboard bearing cover and gasket off the shaft

Remove locknuts and lockwashers

Remove the head capscrews and carefully pry the head away from the casing

Slide the head off the shaft. The head O-ring, bearing, mechanical seal stationary seat and stationary O-ring will come off with the head assembly

Remove and discard the head O-ring

Remove the four disc machine screws and lockwashers to release the disc from the head

Barrier Oil Change

Pump pressure reading

Barrier fluid tank pressure reading

Warning: A small amount of pumping fluid/gas may have leaked into the barrier oil. Take the proper precautions when venting

Seal drain plugs removed from bottom of seal cartridges?

Oil drained from each seal and barrier pot?

Plugs replaced and barrier pot filled with new barrier oil to the seal pot manufacturer recommended volume?

Vane Replacement

NOTICE: Maintenance shall be performed by qualified technicians only. Follow the appropriate procedures and warnings as presented in manual

Drain and relieve pressure from the pump and system as required

Remove the head assembly from the outboard (non-driven) side of the pump

Turn the shaft by hand until a vane comes to the top position of the rotor. Remove the vane

Install a new vane, ensuring that the relief groove is facing toward the direction of rotation

Repeat steps 3 and 4 until all vanes have been replaced

Reassemble the pump

Sign off on the vane replacement

3 Monthly Pump Bearing Lubrication

NOTICE: To avoid possible entanglement in moving parts do not lubricate pump bearings, gear reducer or any other parts while the pump is running

NOTICE: If pumps are repainted in the field, ensure that the grease relief fittings are functioning properly after painting. Do NOT paint them closed. Remove any excess paint from the fittings

Pump bearings lubricated every three months at minimum

Grease relief fittings removed from the bearing covers

Grease applied with a hand gun until grease begins to escape from the grease relief fitting port

Grease relief fittings replaced

Pump bearings not overgreased

Strainers cleaned regularly to avoid pump starvation

Sign off on the pump bearing lubrication

Parts for Blackmer Sliding Vane Pump SGLD2

Access the parts list for your equipment in MaintainX.

O-Ring R/V Cover (PTFE)

702077

Bearing Cover Gasket

383940

Bearing Lockwasher

903522

O-Ring R/V Cover (Neoprene)

711994

O-Ring Flange (PTFE)

702078

O-Ring R/V Cover (PTFE)

702077

Bearing Cover Gasket

383940

Bearing Lockwasher

903522

O-Ring R/V Cover (Neoprene)

711994

O-Ring Flange (PTFE)

702078

O-Ring R/V Cover (PTFE)

702077

Bearing Cover Gasket

383940

Bearing Lockwasher

903522

O-Ring R/V Cover (Neoprene)

711994

O-Ring Flange (PTFE)

702078

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX