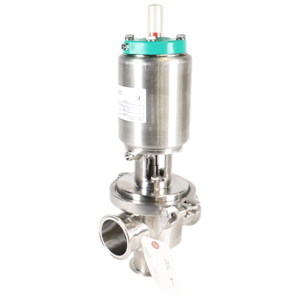

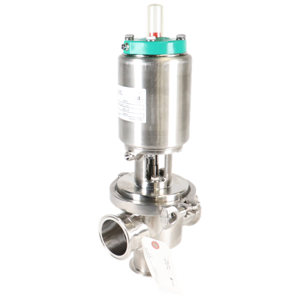

The Alfa Laval Tank Cleaning Machine Gunclean Toftejorg TZ-82 Portable is an efficient solution for tank cleaning in various industrial applications. This portable model ensures thorough cleaning with minimal downtime, making it ideal for maintaining hygiene and operational efficiency in your facility.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Alfa Laval Tank Cleaning Machine Gunclean Toftejorg TZ-82 Portable

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Tank Cleaning Machine Gunclean Toftejorg TZ-82 Portable

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Tank Cleaning Machine Model Gunclean Toftejorg TZ-82 Portable

Integrate maintenance plans directly into your work orders in MaintainX.

Ball Races Replacement

• In Body

1. A. With big end downwards knock several times Body with bearings (pos. 26) hard against firm wooden support until Ball race (pos. 26.3) drops out.

1. B. If it is not possible to knock out Ball race in this way, it is necessary first to screw out Main collar lower (pos. 26.2) - see page 26. Carefully push off old Ball race without damaging Main collar lower. Use mandrel and firm support. Before mounting of new Ball race, main collar lower (pos. 26.2) must be remounted into Body - see page 26.

2. Clean surfaces and place Ball race (pos.26.3) on Main collar lower (pos. 26.2). Press by hand as long as possible. By means of a tube mandrel or if desired wooden block, carefully hammer Ball race home. Ball race must not project over of Main collar lower. To avoid tilting mandrel must push along the whole circumference of Ball race. Do not damage surface of Ball race.

• On Gear wheel

1. Place Gear wheel with ball race (pos. 7) on support. Support only under Ball race (pos. 7.1). With mandrel press off old Ball race.

2. Clean surfaces and press on new Ball race. Ball race must be pressed fully home on Gear. Press parallel. Use press or vice. Do not damage surface of Ball race.

• In Hub cover

1. Place Hub cover with ball race (pos. 19) on support. Carefully knock out old Ball race by means of small mandrel or if desired screwdriver. Knock several times around the circumference to avoid tilting.

Collar Bushes Replacement

Place Gear frame (pos. 29) upside down with a firm support under the flange. Use for instance jaws of a vice. Do not clamp on machined surfaces.

Collar bush knocked out with Pusher (tool No. TE81B033, see page 28)?

Turn Gear frame to upright position and hold over support such as flat steel bar clamped in a vice.

Collar bush knocked out with Pusher?

Turn Gear frame 90° and hold over support.

Collar bush knocked out with Pusher?

Warning: To avoid risk of deforming Gear frame, it is utmost important that it is supported while the Collar bushes are being knocked out.

Holes cleaned and new Collar bushes pushed into Gear frame?

Sign off on the Collar bushes replacement

Main Collars Replacement

• Although normally exposed to very limited wear, it is possible to replace Main collars (pos. 26.1 and 26.2) in Body. The procedure to do this is described below.

Main collar upper

1. Place Body (pos. 26) in a vice in upright position. Do not clamp on machined faces. Insert Tool (see page 29) into Main collar upper (pos. 26.1). Unscrew Main collar.

2. Carefully clean thread and recess in Body. Do not damage special thread in Body. Recess must be absolutely clean.

3. Make sure that new Main collar is clean and free from impurities.

4. Screw in new Main collar. Attention should be given to make sure that thread is in correct engagement before screwing in Main collar.

5. Tighten Main collar fully home, and tighten up.

6. Check that main collar is fully home: Install Stem, Ball retainer with balls and Gear wheel (see page 18). Check that there is sufficient axial clearance to allow for free rotation of Stem.

• Main Collar Lower

Parts for Alfa Laval Tank Cleaning Machine Gunclean Toftejorg TZ-82 Portable

Access the parts list for your equipment in MaintainX.

Gear Wheel, w. ball race

TE712-13

Impeller, 50%

TE705-50

Guide, 50%

TE703-50

Horizontal Shaft

TE828Z

Worm Wheel, E-gear

TE21A564

Gear Wheel, w. ball race

TE712-13

Impeller, 50%

TE705-50

Guide, 50%

TE703-50

Horizontal Shaft

TE828Z

Worm Wheel, E-gear

TE21A564

Gear Wheel, w. ball race

TE712-13

Impeller, 50%

TE705-50

Guide, 50%

TE703-50

Horizontal Shaft

TE828Z

Worm Wheel, E-gear

TE21A564

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX