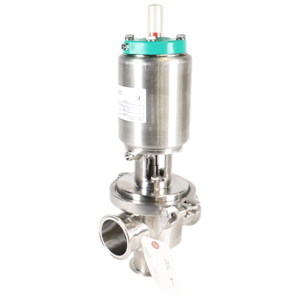

The Alfa Laval Rotary Lobe Displacement Pump GHPD-522 is engineered for efficient fluid transfer in various industrial applications. Known for its reliability and performance, this pump features robust construction and advanced design, ensuring optimal operation and minimal downtime. Ideal for handling viscous fluids, it is a preferred choice in the food, pharmaceutical, and chemical industries.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Alfa Laval Rotary Lobe Displacement Pump GHPD-522

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Rotary Lobe Displacement Pump GHPD-522

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Rotary Lobe Displacement Pump Model GHPD-522

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Pump Maintenance

1. Checking the oil level in the gearcase (if applicable).

2. Checking the mechanical seals for leakage and replacing as necessary.

3. Adjusting the packed glands to control leakage.

4. Checking the oil seals for leakage.

5. Check pumping pressures.;

3000 Hourly Lubrication Oil Replacement

1. The pump will NOT be supplied oil filled.

2. First change - After 150 hours of operation.

3. Fill with oil through the filler plug to the level indicated in the sight glass.;

Flushed Hyclean Seal Replacement

– The seal rotary face is driven by a pin which locates in a slot on the shaft. A washer is located between the shaft shoulder and rotary face. A seal between the rotary face and shaft is provided by an 'O' ring.

– The stationary face is prevented from rotating as it has a flat side which sits in the rotorcase bore. Face to face contact is provided by a wave spring.

– Axial movement of the stationary face is prevented by a retaining clip. An 'O' ring within the rotorcase bore provides a seal onto the stationary face.

– A seal housing encloses the hyclean seal and is seal by an 'O' ring and retained to the rotorcase by socket head cap screws. A lip seal sits within the seal housing and runs on the rotary face, thus providing a seal.

CAUTION! SEAL FACES ARE BRITTLE - TAKE EXTREME CARE WHEN HANDLING. REMOVING THE FLUSHED HYCLEAN SEAL

REMOVING THE FLUSHED HYCLEAN SEAL

1. Carefully support and remove the rotorcase with the seal housing and stationary face still attached.

2. Slide the rotary face from the shaft.

3. Remove the seal housing screws to inspect the seal.

Hyclean Seal Replacement

– The seal rotary face is driven by a pin which locates in a slot on the shaft. A washer is located between the shaft shoulder and rotary face. A seal between the rotary face and shaft is provided by an 'O' ring.

– The stationary face is prevented from rotating as it has a flat side which sits in the rotorcase bore. Face to face contact is provided by a wave spring. Axial movement of the stationary face is prevented by a retaining clip. An 'O' ring within the rotorcase bore provides a seal onto the stationary face.

CAUTION! SEAL FACES ARE BRITTLE - TAKE EXTREME CARE WHEN HANDLING.

REMOVING THE HYCLEAN SEAL

1. Carefully support and remove the rotorcase with the stationary sealing face still within its bore.

2. Slide the remaining rotary face from the shaft.

3. Release the retaining clip and remove the stationary face for inspection.

FITTING THE HYCLEAN SEAL

1. Use solvent to wipe the lapped surface of the seal faces until PERFECTLY clean, being extremely careful not to scratch the faces.

Pressure Relief Valve Replacement

CAUTION! COMPLETE DISASSEMBLY IS ONLY REQUIRED IF THE 'O' RINGS OR SPRINGS ARE TO BE REPLACED.

- The relief valve should not be disassembled while the plug is in operation. Always observe the safety precautions detailed at the front of this manual.

- Take extreme care when removing the springs as they have been compressed.

• Disassembly

1. Remove the valve housing.

2. Release and remove the notched nuts) with the spring adjuster.

3. Take off the springs, release the socket head cap screws and remove the valve guide.

4. Access to the pneumatic piston 'O' rings is achieved by releasing the circlip which locates in the valve shaft.

5. The hydraulic piston with the shaft may be lifted out of the front cover once the backstop disc is removed.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX