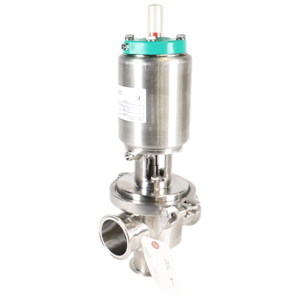

The Alfa Laval Flo-Diversion Valve U7711 is a high-performance valve designed for efficient fluid management in industrial applications. Known for its reliability and precision, this valve optimizes flow control and enhances system performance, making it an essential component in various processing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Alfa Laval Flo-Diversion Valve U7711

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Flo-Diversion Valve U7711

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Flo-Diversion Valve Model U7711

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Valve Maintenance

Check for leakage in product wetted seals

If leakage is found, replace the seals immediately

Upload a photo of the replaced seals

Lubricate product wetted seals with USDA H1 approved oil/grease

Sign off on the valve maintenance

5 Yearly Actuator Maintenance

Replace actuator bushings complete depending on working conditions

Replace actuator bushings complete when possible, after leakage (leakage normally starts slowly)

Lubricate before fitting with Molykote Long term 2 Plus

Actuator bushing replacement

Unscrew and remove top and bottom bushings with O-rings

Lubricate O-rings with Molykote Longterm 2 plus before fitting

Fit bushings and O-rings

Tighten brushing with a torque = 7 lbf-ft (10Nm)

Be careful not to overtighten

Actuator Maintenance

Inspect for leakage

Check for smooth operation

Record of the valve

Use the statistics for planning of inspections

Replace after leakage?

Sign off on the actuator maintenance

Valve Test

Warning: This procedure requires trained personnel with PPE!

Are the valves properly assembled?

Is the temperature sensing element of the Safety Thermal Limit Recorder Controller below legal pasteurization temperature?

Is the flow promoting device (timing pump) operating properly?

Is the seal wire on ThinkTop cover hold down screws broken?

Is the gauge spacer installed at top of magnet?

Can you push down on outer ring of indication stem magnet and remove spacer between the stem and magnet?

Is the required air applied to the actuator for normal operating conditions?

Is the selector switch in the “Product” position and the flow promoting device (timing pump) not starting?

Bushing and Seat/Seal Replacement

TR2 and Elastomer seat ring replacement

Remove old seal ring without damaging metal parts

Pre-mount plug seal without pressing it into the groove

Squeeze plug seal into the groove using opposite pressure points

Release compressed air behind plug seal

TR2 plug replacement

Cut through the upper ring portion of the TR2 plug avoiding contact with stainless steel stem

Force apart both cut ends of the plug for removal from stem

Install TR2 plugs by applying uniform pressure on all sides

Parts for Alfa Laval Flo-Diversion Valve U7711

Access the parts list for your equipment in MaintainX.

O-ring

9614-0594-24

Plug

9613-1277-26

Plug

9613-1277-02

Plug

9613-1277-14

Plug Seal

9614-0594-07

O-ring

9614-0594-24

Plug

9613-1277-26

Plug

9613-1277-02

Plug

9613-1277-14

Plug Seal

9614-0594-07

O-ring

9614-0594-24

Plug

9613-1277-26

Plug

9613-1277-02

Plug

9613-1277-14

Plug Seal

9614-0594-07

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX