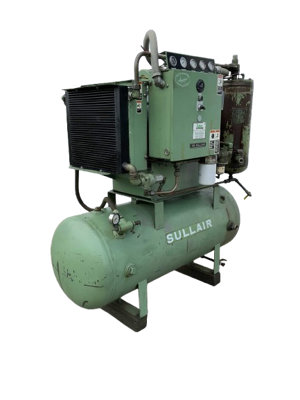

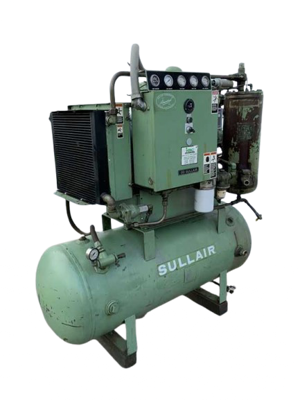

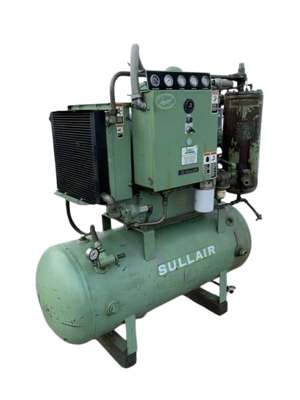

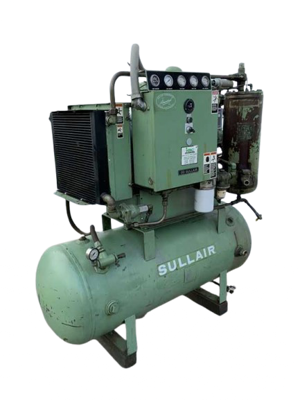

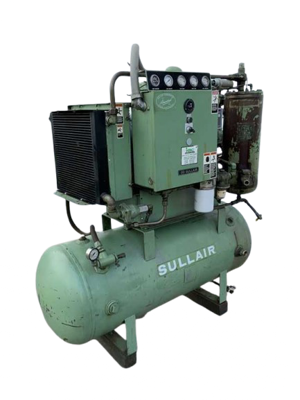

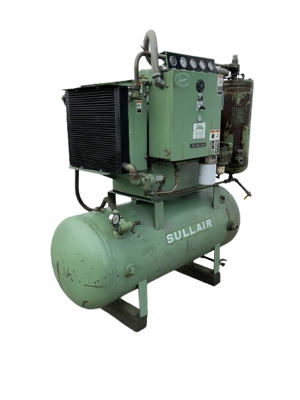

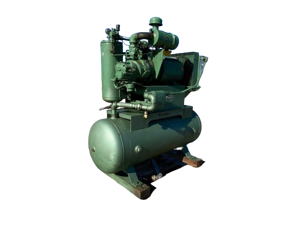

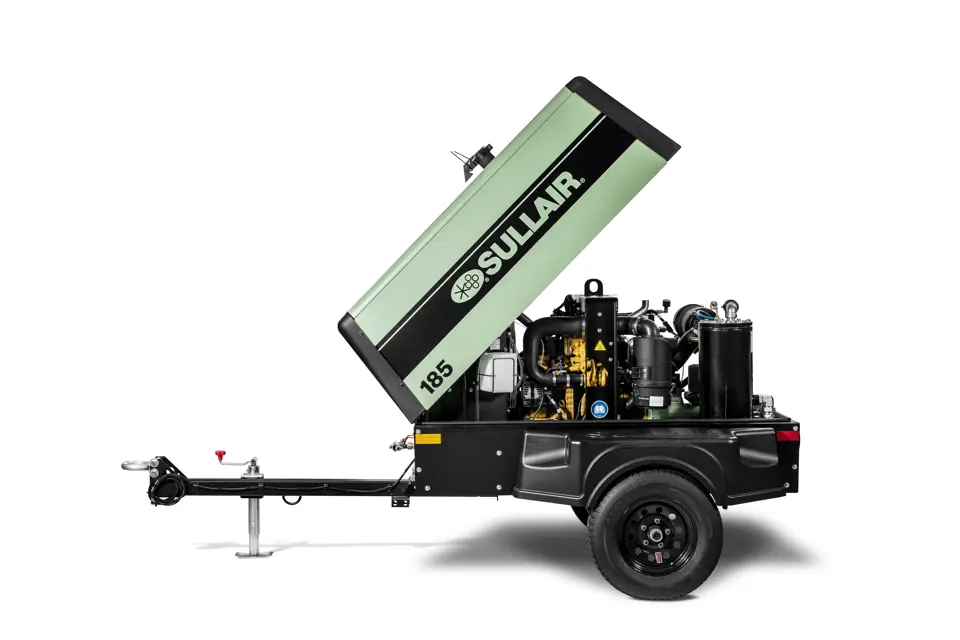

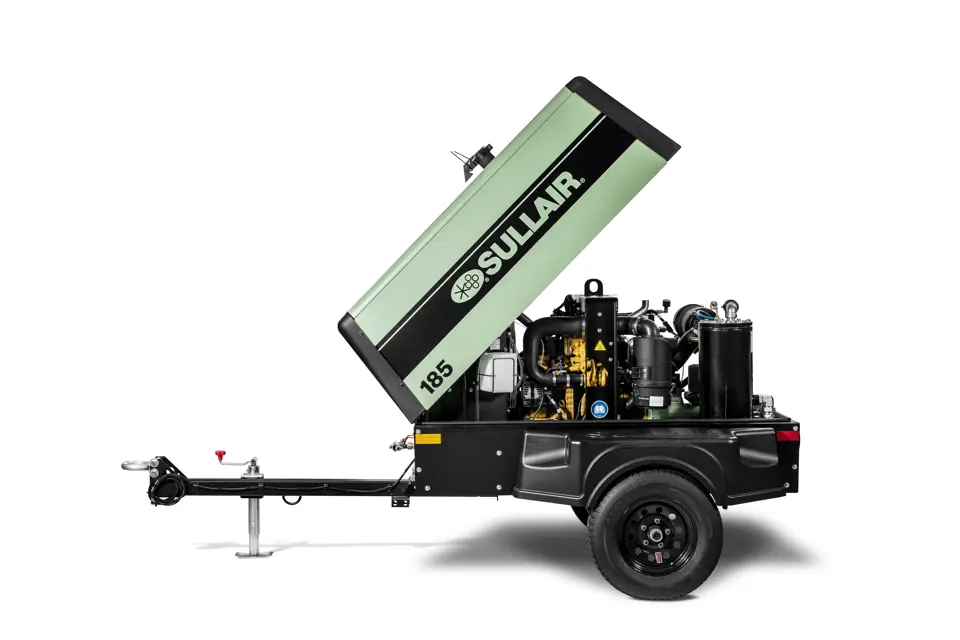

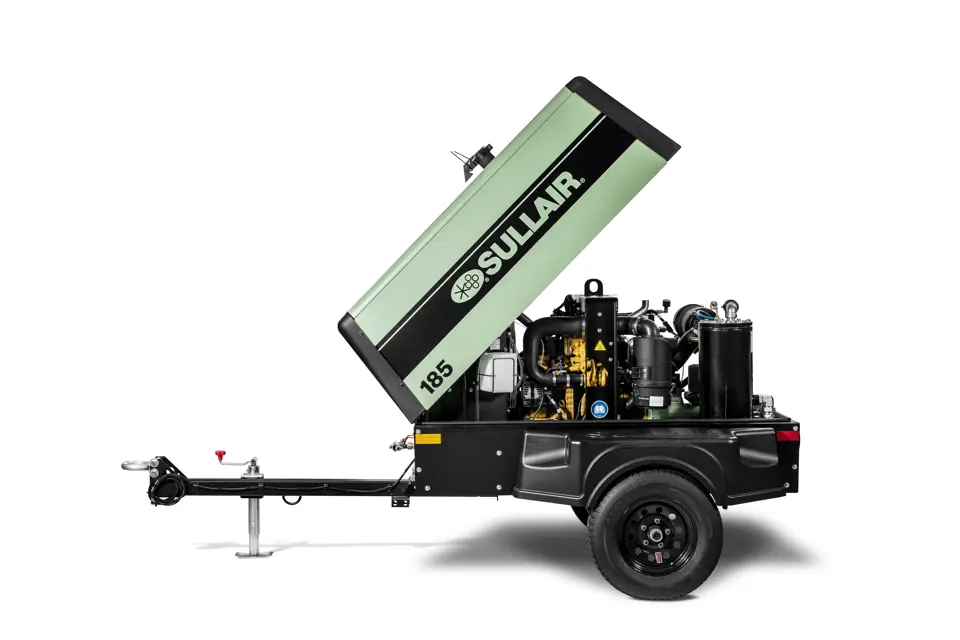

The Sullair Portable Air Compressor 185DPQPERK is a robust and efficient industrial air compressor designed for various applications. Known for its reliability and performance, this model ensures optimal air delivery and durability in demanding environments, making it an essential asset for construction and maintenance tasks.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Portable Air Compressor 185DPQPERK

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Portable Air Compressor 185DPQPERK

Create an account to install this asset package.

Maintenance Plans for Sullair Portable Air Compressor Model 185DPQPERK

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 50 Hours Compressor Maintenance

Clean the return line orifice and check the strainer

Change the compressor fluid filter

Check the Engine Operator’s Manual for service requirements

Check the fuel filter for water

Confirm that the receiver tank cover bolts are tightened to 60 lbf ft (81 N m)

Sign off on the compressor maintenance

1500 Hour Compressor Fluid Filter Element Replacement

Warning: This procedure should be performed by trained personnel only

Compressor run for 5-10 minutes to warm the fluid

Compressor shut down and all internal pressure relieved

Fluid sump drained by removing the plug or opening the valve at the bottom of the sump tank

Compressor fluid changed and fluid filter element replaced

Amount of fluid filled in the sump

Sign off on the compressor fluid filter element replacement

1500 Hour / 12 Monthly Compressor Bearing Lubrication

Lubricate axle bearings on wheel-mounted units

Proper lubrication of the portable compressor's bearing axle is critical to its proper function and reduction of wear on this part.

Use a wheel bearing grease that conforms to MILSPEC MIL-G-10924 or a high temperature one such as lithium complex NLGI consistency #2

Axles with the E-Z Lube feature can be periodically lubricated without removing the hubs from the axle.

Remove the rubber cap from the grease cap's end

Using a full charged grease gun, place the gun onto the grease zerk located on the end of the spindle. Make sure the nozzle is fully engaged on the fitting

Pump grease into the zerk. The old grease will be displaced and flow out of the cap around the grease gun nozzle

When the new grease starts flowing out of the cap, disengage the gun and wipe off any excess off the cap; and replace the rubber plug

Sign off on the compressor bearing lubrication

50 Hour Compressor Air Filter Inspection

Inspect air filter element for any light leaks indicating damage

Inspect all gaskets and gasket contact surfaces of the housing for any damage

Store clean elements for later use in a clean container

Inspect and tighten all air inlet connections before operating the compressor

Sign off on the air filter inspection

50 Hour Compressor Air Filter Replacement

Loosen and remove the air filter and cover

Remove the primary and optional secondary elements

Clean the body, inside and out, with a damp cloth

Reinstall (if clean) or replace the secondary element if installed

Replace the new primary filter element

Reposition the cover and lock it into the position

Reset the filter restriction indicator (if equipped)

Sign off on the air filter replacement

Parts for Sullair Portable Air Compressor 185DPQPERK

Access the parts list for your equipment in MaintainX.

All Weather Fluid

250030-757

Separator Element

88291009-563

All Weather Fluid

250030-758

All Weather Fluid

250030-757

Separator Element

88291009-563

All Weather Fluid

250030-758

All Weather Fluid

250030-757

Separator Element

88291009-563

All Weather Fluid

250030-758

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX