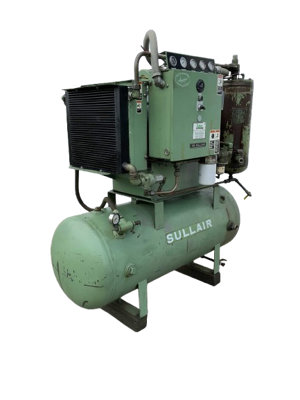

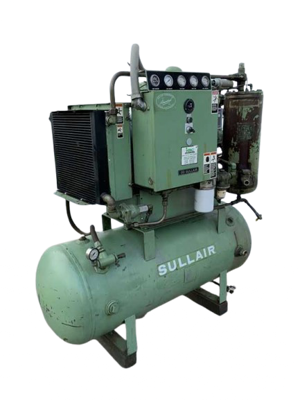

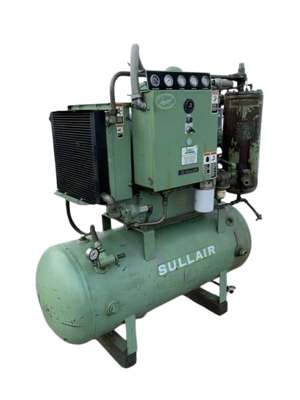

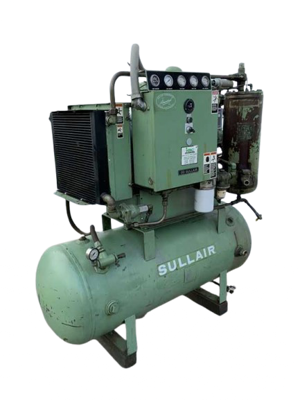

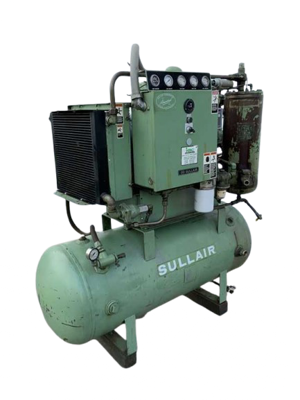

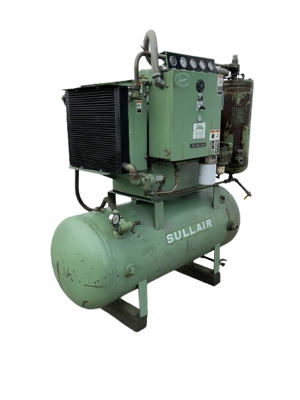

The Sullair Portable Air Compressor 185DPQ-JD is a robust and efficient solution for various industrial applications. Known for its reliability and performance, this model delivers high-quality compressed air, making it ideal for construction and maintenance tasks. Optimize your operations with this powerful compressor from Sullair.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Portable Air Compressor 185DPQ-JD

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Portable Air Compressor 185DPQ-JD

Create an account to install this asset package.

Maintenance Plans for Sullair Portable Air Compressor Model 185DPQ-JD

Integrate maintenance plans directly into your work orders in MaintainX.

50 Hour Compressor Air Filter Inspection

Insert a bright light source into the element and look for any light leaks which indicate the presence of damage (holes, cracks, etc.)

Inspect all gaskets and gasket contact surfaces of the housing and replace any damaged ones

Store clean elements for later use in a clean container

After installing the element, inspect and tighten all air inlet connections before operating the compressor

Sign off on the air filter inspection

250 Hour Compressor Maintenance

CAUTION: Operating the compressor below its minimum specified idle speed will damage the compressor. Operating the compressor in this condition will cause coupling and/or compressor failure

Clean the radiator and cooler exterior surfaces every 100 hours

Check the Engine Operator’s Manual for service requirements every 100 hours

Check fan belt tension

Clean the radiator and cooler exterior surfaces

Check the Engine Operator's Manual for service requirements

Change the engine oil and filter

Clean or replace the return line strainer

Change the air filter primary elements

1500 Hour Compressor Fluid Replacement

Change fluid filter

Remove the old element with a strap wrench

Clean the gasket seating surface

Apply a light coating of fluid to the new gasket

Hand tighten the new element until the new gasket is seated

Continue tightening the element by hand an additional 1⁄2 to 3⁄4 turn

Restart the compressor and check for leaks

Sign off on the fluid replacement

1500 Hour / 12 Monthly Compressor Bearing Lubrication

Warning: Proper lubrication of the portable compressor's bearing axle is critical to its proper function and reduction of wear on this part.

Use a wheel bearing grease that conforms to MILSPEC MIL-G-10924 or a high temperature one such as lithium complex NLGI consistency #2

Axles with the E-Z Lube feature can be periodically lubricated without removing the hubs from the axle.

Remove the rubber cap from the grease cap's end

Using a full charged grease gun, place the gun onto the grease zerk located on the end of the spindle. Make sure the nozzle is fully engaged on the fitting

Pump grease into the zerk. The old grease will be displaced and flow out of the cap around the grease gun nozzle

When the new grease starts flowing out of the cap, disengage the gun and wipe off any excess off the cap; and replace the rubber plug

Sign off on the compressor bearing lubrication

Compressor Separator Element Replacement

Warning: This procedure requires trained personnel with PPE!

Compressor fluid carryover evident?

Fluid return line strainer and orifice in satisfactory condition?

Blowdown valve in satisfactory condition?

Enter the part number for the new separator element

Old element removed with a strap wrench?

Gasket seating surface cleaned?

Light coating of fluid applied to the new gasket?

New element hand tightened until the new gasket is seated?

Parts for Sullair Portable Air Compressor 185DPQ-JD

Access the parts list for your equipment in MaintainX.

Separator Element

88291009-563

All Weather Fluid

250030-758

All Weather Fluid

250030-757

Separator Element

88291009-563

All Weather Fluid

250030-758

All Weather Fluid

250030-757

Separator Element

88291009-563

All Weather Fluid

250030-758

All Weather Fluid

250030-757

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX