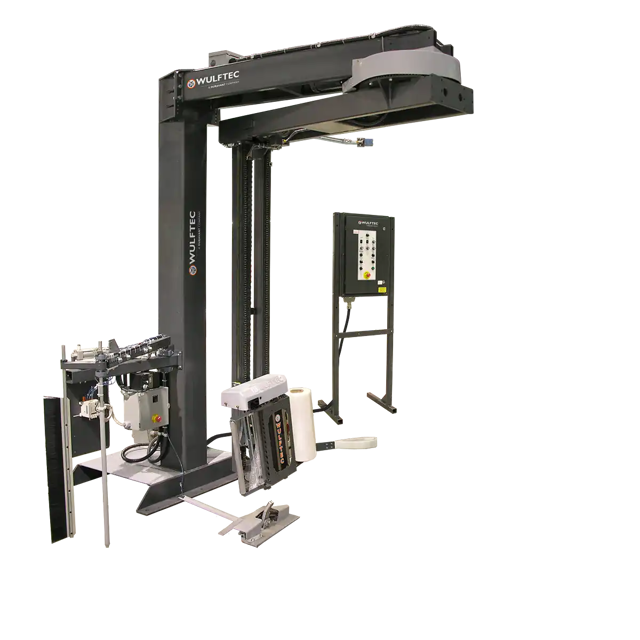

The Wulftec Automatic Rotary Arm Stretch Wrapper WRTA-150 is designed for efficient and reliable packaging solutions in industrial settings. This advanced stretch wrapper optimizes film usage while ensuring secure load stability, making it an essential asset for any production line. Enhance your operations with this high-performance equipment.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Wulftec Automatic Rotary Arm Stretch Wrapper WRTA-150

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Wulftec Automatic Rotary Arm Stretch Wrapper WRTA-150

Create an account to install this asset package.

Maintenance Plans for Wulftec Automatic Rotary Arm Stretch Wrapper Model WRTA-150

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Pre-Stretch Chain Adjustment Check

Pre-stretch chains have proper tension

Enter the play per foot of chain

Motor chain adjusted

Pre-stretch chain tension adjusted using the cam & sprocket

Commutator cleaned

Pivot points greased

Oil sample taken after 1000 Hours of operation

Oil changes made after 25000 Hours

All chains greased

1 Monthly Ring Gear Teeth Inspection

Visually inspect the teeth

Remove buildup if present

Select the type of pinion

If steel pinion, apply grease with a brush all around ring gear

Type of grease used

If nylon pinion, no greasing is necessary

Backlash between gear and pinion

Sign off on the gear teeth inspection

2000 Hourly Pre-Stretch Belts Adjustment Check

Warning: This procedure requires trained personnel with PPE!

Pre-stretch belts checked for proper tension

Enter the deflection per inch of belt span

Motor drive belt adjusted by loosening the four (4) motor mounting bolts and sliding the motor in the mounting slots

Pre-stretch belt tension adjusted with the tension adjustment arm

Tension adjustment arm rotated and moved within the mounting slot to obtain correct tension

Upload a photo of the adjusted pre-stretch belt

Photoeye and reflectors cleaned

Carriage rails greased with all-purpose grease

1 Monthly Ring Gear Bearing Inspection

Lubrication of the bearing component is provided through the auto-lube system. Operation of the auto-lube is detailed in the annex.

Inspect the grease container of the auto-lube and refill with EP2 grease as required

For machines without the auto-lube system, apply EP2 grease with a grease pump every month, or as part of your regular maintenance program.

Move bearing several times to ensure complete fill

Inspect the seals to ensure they are properly inserted into their grooves and that they are intact and preventing contaminants from entering the bearing

Parts for Wulftec Automatic Rotary Arm Stretch Wrapper WRTA-150

Access the parts list for your equipment in MaintainX.

Lock Nut

0ECNT00196

Breaker

0EFUS00307

Base Relay

0ERLY00166

PVC Shield

0ECAB00244

Breaker

0EFUS00361

Lock Nut

0ECNT00196

Breaker

0EFUS00307

Base Relay

0ERLY00166

PVC Shield

0ECAB00244

Breaker

0EFUS00361

Lock Nut

0ECNT00196

Breaker

0EFUS00307

Base Relay

0ERLY00166

PVC Shield

0ECAB00244

Breaker

0EFUS00361

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX