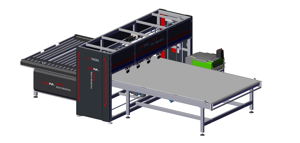

The United Mert Makina Roll Pack Machine UMM-SPK-3D-Alpha is a high-performance industrial asset designed for efficient packaging solutions. This advanced machine combines reliability and precision, making it ideal for various manufacturing processes. Optimize your production line with this state-of-the-art roll pack machine.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

United Mert Makina Roll Pack Machine UMM-SPK-3D-Alpha

Create an account to install this asset package.

Maintenance Plans for United Mert Makina Roll Pack Machine Model UMM-SPK-3D-Alpha

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Machine Maintenance

Change the oil of the gearbox with SYNTHETIC VG320

Lubricate the chain with grease (p.288)

Remove the upper cover (p.293)

Is the cutting quality of the blade satisfactory?

If not, replace the upper cover with a new one

Check the hydraulic oil level from the indicated gauge (p.294)

Sign off on the machine maintenance

3 Monthly Machine Maintenance

Tighten the setskur bolts the gears

Lubricate the setskur bolts the gears

Warning; Power off the machine during the lubrication process

Perform chain lubrication from the parts where the gears are located

Check the valves on the air panel and the unions on the pistons every 3 months. If there is an air leak, remove it (p.288)

Every 3 months, check the oil of the lubricating unit. Check the air pressure of the regulator once a month (p.288);

1 Weekly Machine Maintenance

Check the pistons for air leaks

Check the position of the limit switch

Check the sharpness of the stretch cutter blades

Check the tension of the resistance wire

If any issues were found, describe them here

Sign off on the weekly machine maintenance

1 Daily Machine Maintenance

Cut off electricity the 3D Full Pack machine before starting maintenance

Air must be blown into the machine daily to clean the fabric, rope residue and etc.

Clean the sensors daily with an air gun (p.286)

Clean the limit switch daily with air (298);

1 Monthly Machine Maintenance

Lubricate the roller bearings with grease

Lubricate the linear slider with grease

Check the tension of the thread emergency stop switch

Replace it with a new one, if necessary, depending on the cutting quality of the blade

Check the tension of the belts

Lubricate the bearings with grease

Check the tightness of the gear setscrews

Sign off on the machine maintenance

Parts for United Mert Makina Roll Pack Machine UMM-SPK-3D-Alpha

Access the parts list for your equipment in MaintainX.

Air Jet And Record

S001500

Single Row Chain / Single Row Lock Assembly

SR-Chain-Lock-3D-Alpha

RZT-Piston Sensor

S001533

Emergency Stop Button

S000302

30X10 3 Rubber Cover Tire (Per Meter)

30x10-3RUB

Air Jet And Record

S001500

Single Row Chain / Single Row Lock Assembly

SR-Chain-Lock-3D-Alpha

RZT-Piston Sensor

S001533

Emergency Stop Button

S000302

30X10 3 Rubber Cover Tire (Per Meter)

30x10-3RUB

Air Jet And Record

S001500

Single Row Chain / Single Row Lock Assembly

SR-Chain-Lock-3D-Alpha

RZT-Piston Sensor

S001533

Emergency Stop Button

S000302

30X10 3 Rubber Cover Tire (Per Meter)

30x10-3RUB

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX