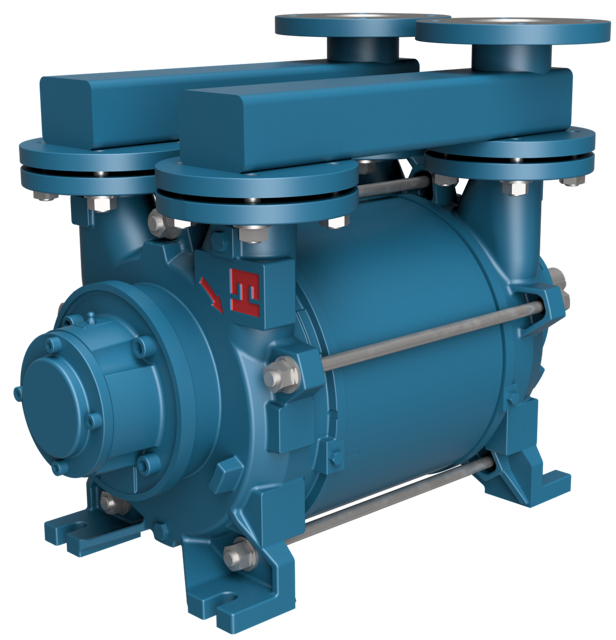

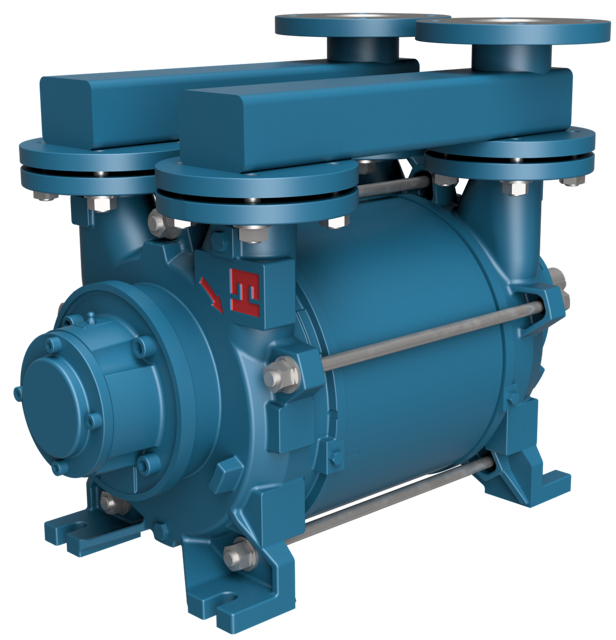

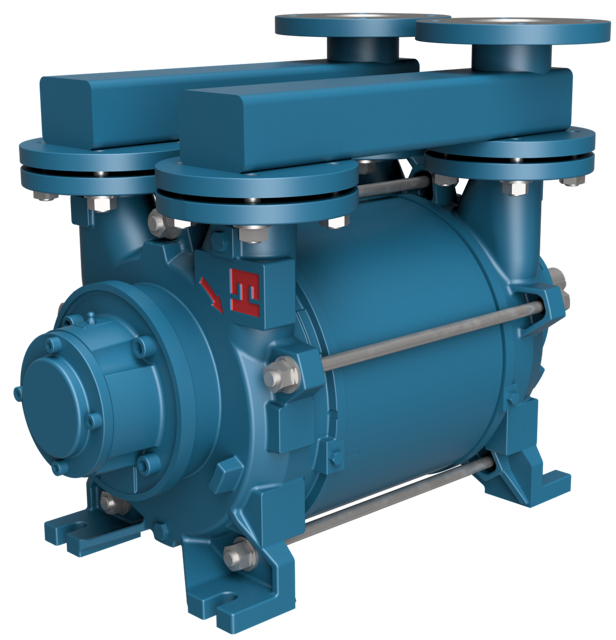

The Travaini Vacuum Pump TR0600V-1A is a high-performance industrial vacuum pump designed for efficient operation in various applications. Known for its reliability and durability, this model ensures optimal vacuum levels while minimizing maintenance needs, making it an essential asset for any industrial setting.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Travaini Vacuum pump TR0600V-1A

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Travaini Vacuum pump TR0600V-1A

Create an account to install this asset package.

Maintenance Plans for Travaini Vacuum pump Model TR0600V-1A

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly Pump Inspection

Safety & Environmental Precautions

Area is free of vibrations, moisture, and contaminants

Appropriate PPE is worn when handling rust-inhibitor liquids or protective materials

If temperatures are below 5°C, has anti-freeze or complete draining occurred

Inspection & Maintenance Steps

Pump shaft rotated by hand to prevent rust build-up and internal component seizing

Pump body and internals checked for signs of rust, moisture ingress, or corrosion

Protective plastic sheeting or covers inspected for integrity and replaced if damaged

All openings remain sealed to prevent air or humidity entry

1 Yearly / 2000 Hourly Bearings Lubrication

Safety Precautions

Safety Measures

Lubrication Interval

Lubrication Interval: Every 2000–2500 working hours or once per year, whichever comes first.

Lubrication Procedure

Lubrication Steps

Sign off on the bearings lubrication

2 Monthly Packing Rings Replacement

Note: In the event the pump remains out of service for more than 2 months it is recommended to replace the packing rings, prior to start-up.

Safety Precautions:

1. ⚠️ Ensure the pump is not running before performing any adjustment or replacement.

2. Wear appropriate PPE to protect from hot or hazardous fluids.

3. Follow lockout/tagout and safety procedures per Chapter 2 of the manual.

Replacement Procedure:

1. Drain any remaining pumped fluid and relieve internal pressure.

2. Remove safety guards and loosen adjusting bolts and nuts on the packing gland.

3. Remove worn packing rings using the appropriate extraction tools.

15000 Hourly Bearing Replacement

Shut down and cool the pump completely. Disconnect power and isolate the unit.

Upload a photo of the isolated unit.

Refer to the 'Disassembly and Assembly Instructions' for your pump model (see manual reference).

Remove old bearings. Clean bearing housings thoroughly.

Upload a photo of the cleaned bearing housings.

Install new bearings of correct type

Apply correct grease type and amount

Test run pump and check for abnormal noise, heat, or vibration.

Sign off on the bearing replacement.

4000 Hourly Wear of Seal Faces Check

Safety Precautions

Used personal protective equipment (PPE)?

System turned off, isolated, and depressurized before opening seal areas?

Any leaks contained and reported immediately?

Inspection Procedure

Accessed the mechanical seal assembly and removed any covers or guards necessary to inspect the seal?

Visually inspected the seal faces for wear, scoring, or surface damage?

Checked O-rings and elastomers for cracking or deformation due to heat or wear?

Ensured flushing liquid is present – seals should never run dry?

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX