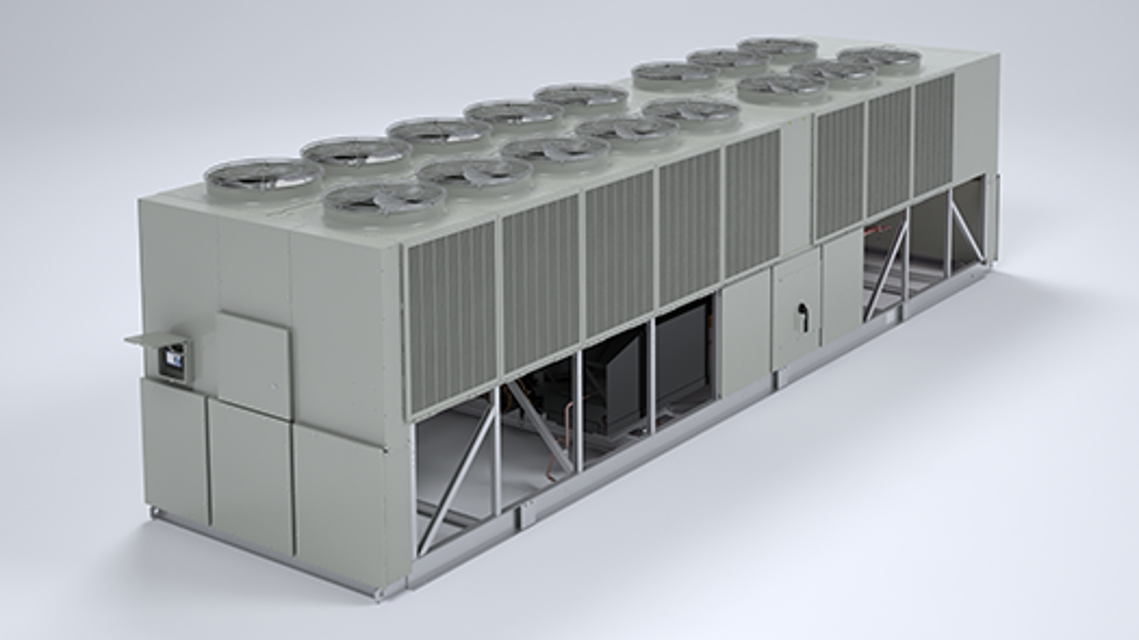

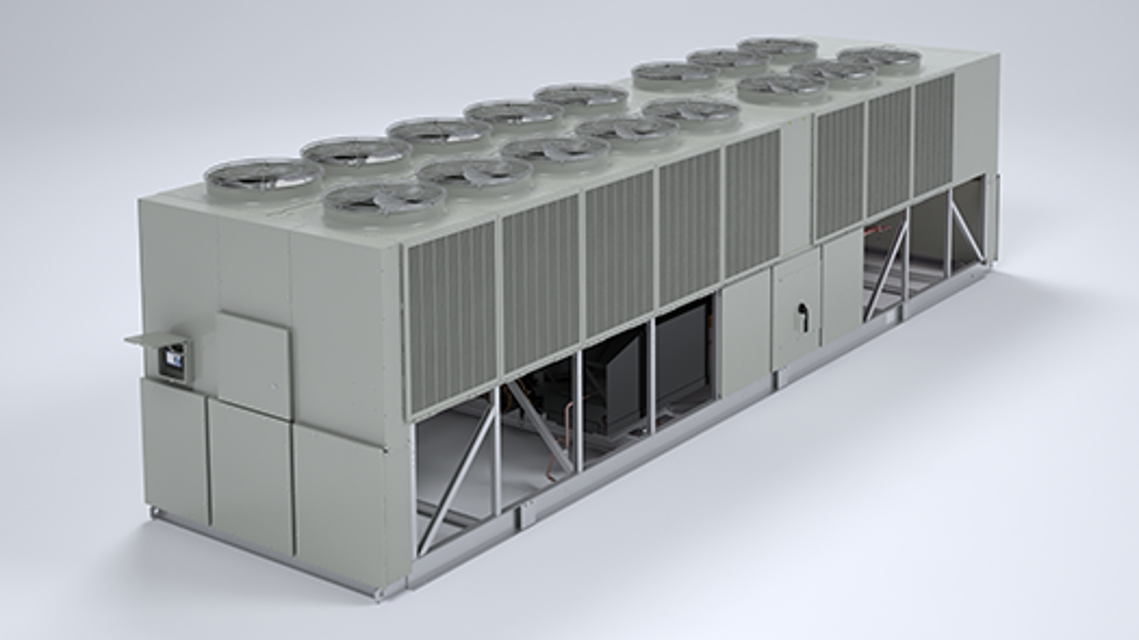

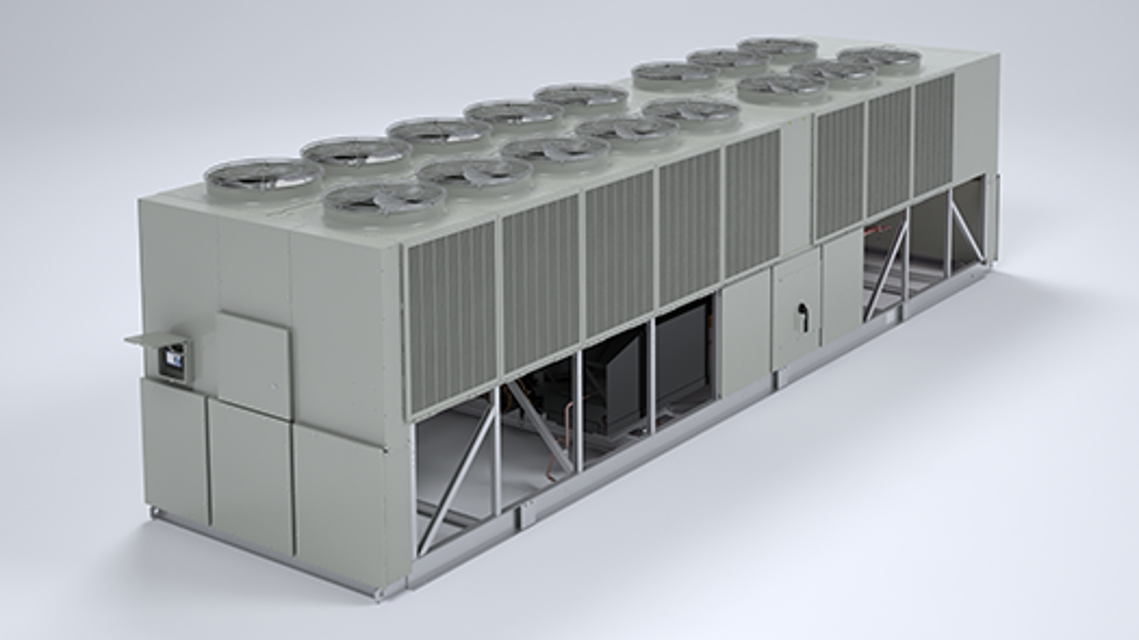

The Trane Series R™ Helical Rotary Chiller RTAC350X is a high-efficiency industrial chiller designed for optimal cooling performance. With advanced technology and robust construction, it ensures reliable operation and energy savings in commercial applications. Ideal for large facilities, this model provides exceptional reliability and serviceability.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC350X

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC350X

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC350X

Integrate maintenance plans directly into your work orders in MaintainX.

High Side Charge Isolation

Circuit is off

Liquid line service valve is shut

Oil return line service valve is shut

Circuit started with the service tool (access compressor service view in Techview)

Discharge check valve closed after unit trips

Discharge isolation valve is closed

Oil line shut off valve is closed

Refrigerant remainder recovered

NOTE: Remaining vapor can be recovered/stored in the high side of the system. Be certain to follow proper recovery procedures to avoid introduction of non-condensable gases.

1 Weekly Series R™ Helical Rotary Chiller Maintenance

While unit is running in stable conditions

Check MP pressure for evaporator, condenser and intermediate oil

Observe liquid line sight glass on EXV

If liquid line sight glass has bubbles measure the subcooling entering the EXV. The subcooling should never be less than 4 °F under any circumstances

A clear sightglass alone does not mean that the system is properly charged. Also check the rest of the system operating conditions

Inspect the entire system for unusual conditions and inspect the condenser coils for dirt and debris. If the coils are dirty, refer to coil cleaning

Sign off on the weekly maintenance

Refrigerant Filter Replacement

Warning: This procedure requires trained personnel with PPE!

Temperature downstream of the filter is 8°F (4.4°C) lower than the upstream temperature?

Is the unit undercharged?

Ensure proper subcooling before taking temperature readings.

Is the EXV closed with the unit off?

Is the liquid line isolation valve closed?

Is the ball valve on oil cooler liquid line closed (for units with remote evaporators or oil cooling circuits)?

Attach a photo of the attached hose to service port on liquid line filter flange.

Is the refrigerant from liquid line evacuated and stored?

Inspection Checklist

Inspect the individual pieces of the shipment for obvious damage

Inspect the unit for concealed damage

If concealed damage is discovered, stop unpacking the shipment.

Upload photos of the damage

Provide evidence that the damage did not occur after delivery

Notify the carrier’s terminal of the damage immediately, by phone and by mail.

Notify the Trane sales representative and arrange for repair.

Was the damage inspected by the carrier’s representative before repair?

Sign off on the inspection checklist

Factory (initial) Refrigerant Charging Procedure

Verify that the EXVs are OPEN

Attach vacuum hoses to evaporator service valves (one per circuit)

Open service valves

Attach charging hoses to the charging port on the liquid line filter (one per circuit)

Begin semi-automatic vacuum procedure

When vacuum is complete (indicated), manually isolate the unit from vacuum

Charge unit through the filter housing port per Table 1 - Table 4

When charging is complete, shut evaporator service valve

Disconnect vacuum and charging hoses

Parts for Trane Series R™ Helical Rotary Chiller RTAC350X

Access the parts list for your equipment in MaintainX.

Isolator

X10140305640

Isolator

X10140305640

Isolator

X10140305640

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX