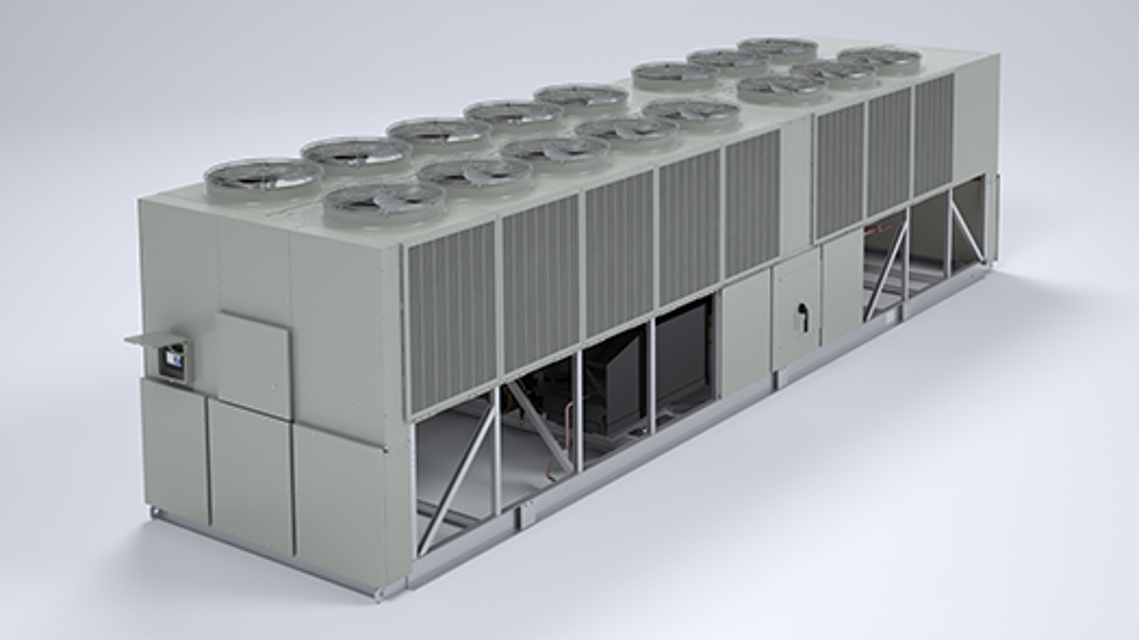

The Trane Series R™ Helical Rotary Chiller RTAC275H is a high-efficiency industrial chiller designed for optimal cooling performance. With advanced technology and robust construction, it ensures reliable operation and energy savings in commercial applications. Ideal for large facilities, this model offers exceptional reliability and serviceability.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC275H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC275H

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC275H

Integrate maintenance plans directly into your work orders in MaintainX.

Neoprene Isolator Replacement

Warning: Ensure you are wearing appropriate PPE before starting the procedure.

Secure the isolators to the mounting surface using the mounting slots in the isolator base plate.

Align the mounting holes in the base of the unit with the threaded positioning pins on the top of the isolators.

Lower the unit onto the isolators and secure the isolator to the unit with a nut.

Enter the isolator deflection (should be 1/4 inch or 6 mm)

Level the unit carefully.

Fully tighten the isolator mounting bolts.

Sign off on the isolator replacement

Clearances

Ensure enough space around the outdoor unit for unrestricted access to all service points.

Enter the unit dimensions as per submittal drawings

Enter the minimum clearance for compressor service (Recommended: 4 feet or 1.2 m)

Is there sufficient clearance for the opening of control panel doors?

Ensure unobstructed flow of condenser air to maintain chiller capacity and operating efficiency.

Is there sufficient flow of air across the condenser heat transfer surface?

Is there any warm air recirculation or coil starvation?

Ensure no debris, trash, supplies etc. accumulate in the vicinity of the unit.

Is the condenser coil free of debris?

Factory (initial) Oil Charging

Warning: This procedure requires trained personnel with PPE!

Is the unit new or has had all of the oil removed?

If not, report the issues to the maintenance team and stop the procedure

Isolation valves closed?

High side of the system not pressurized?

Oil line shut off valve open?

Oil charging port open?

Choose the method of oil charging

CAUTION: Use only Trane OIL00048 in the RTAC units to avoid any catastrophic damage to the compressor or unit.

Inspection Checklist

Inspect the individual pieces of the shipment for obvious damage

Inspect the unit for concealed damage

Date of concealed damage report

Upload photos of the damage

Evidence that the damage did not occur after delivery

Notify the carrier’s terminal of the damage immediately, by phone and by mail

Notify the Trane sales representative and arrange for repair

Do not repair the unit until damage is inspected by the carrier’s representative

Sign off on the inspection checklist

Field Refrigerant Charging

CAUTION: Evaporator Damage! Water must be flowing through the evaporator during the entire charging process to avoid freezing and rupturing of the evaporator tubes. Charge first with vapor to avoid freezing tubes.

Note the weight of the amount of charge removed.

Compare the weight of the charge removed to Table 1 - Table 4. Is there a difference in charge?

A difference in charge may indicate a leak.

Attach a photo of the attached charging hose to evaporator service valve (3/8” (9mm) flare).

Is the service valve open?

Add charge to evaporator to bring total circuit charge up to the level indicated in the above chart.

Is the service valve closed?

Attach a photo of the disconnected charging hose.

Parts for Trane Series R™ Helical Rotary Chiller RTAC275H

Access the parts list for your equipment in MaintainX.

Isolator

X10140305640

Isolator

X10140305640

Isolator

X10140305640

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX