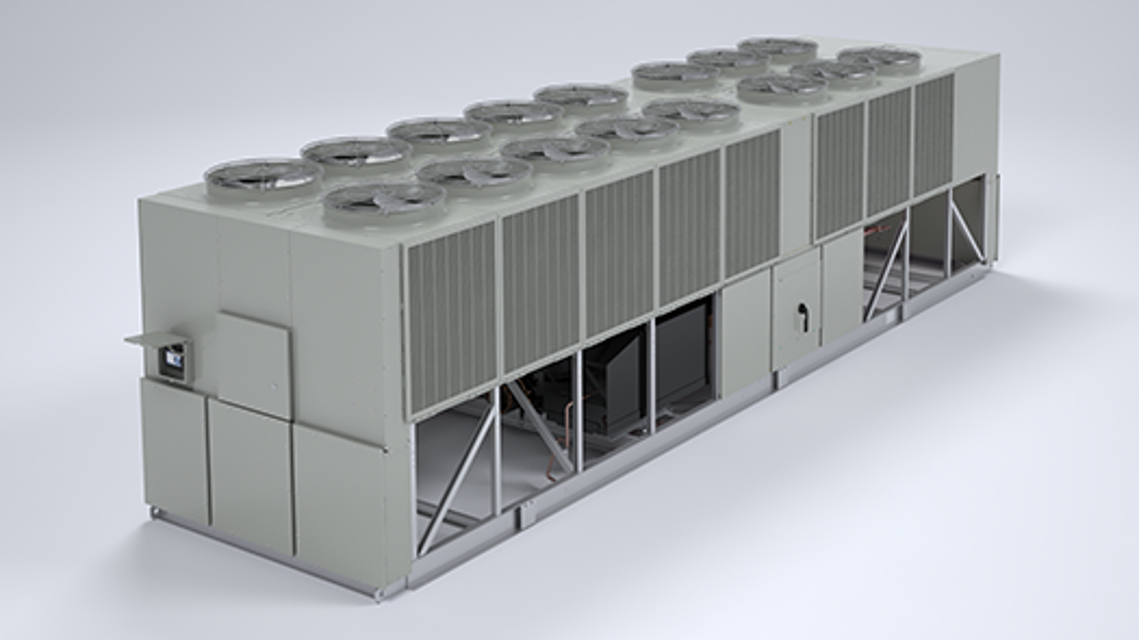

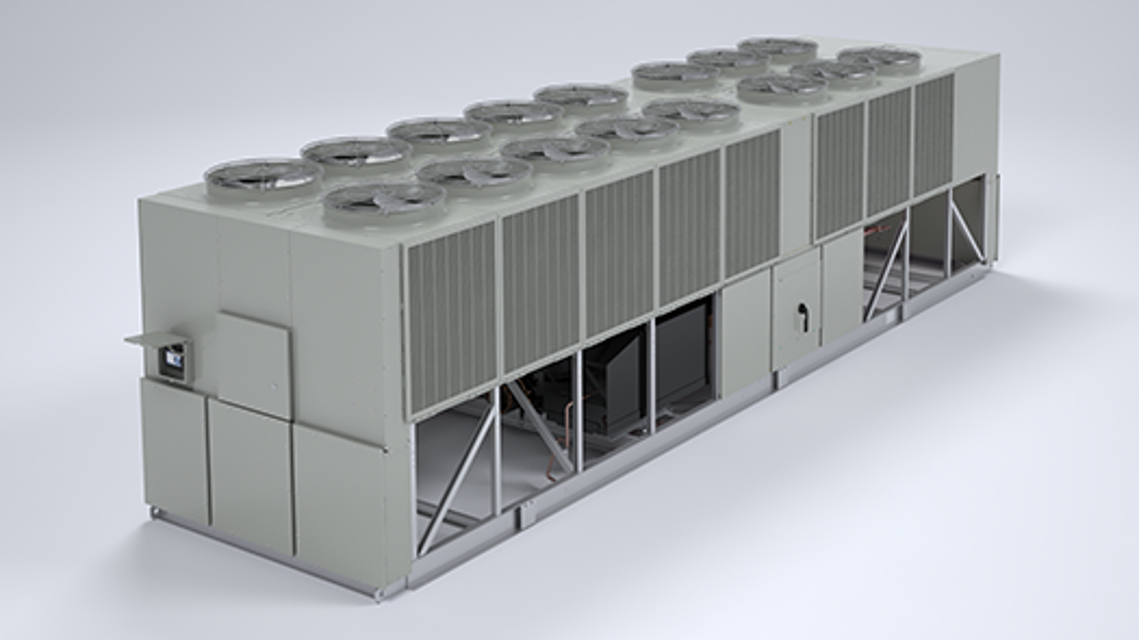

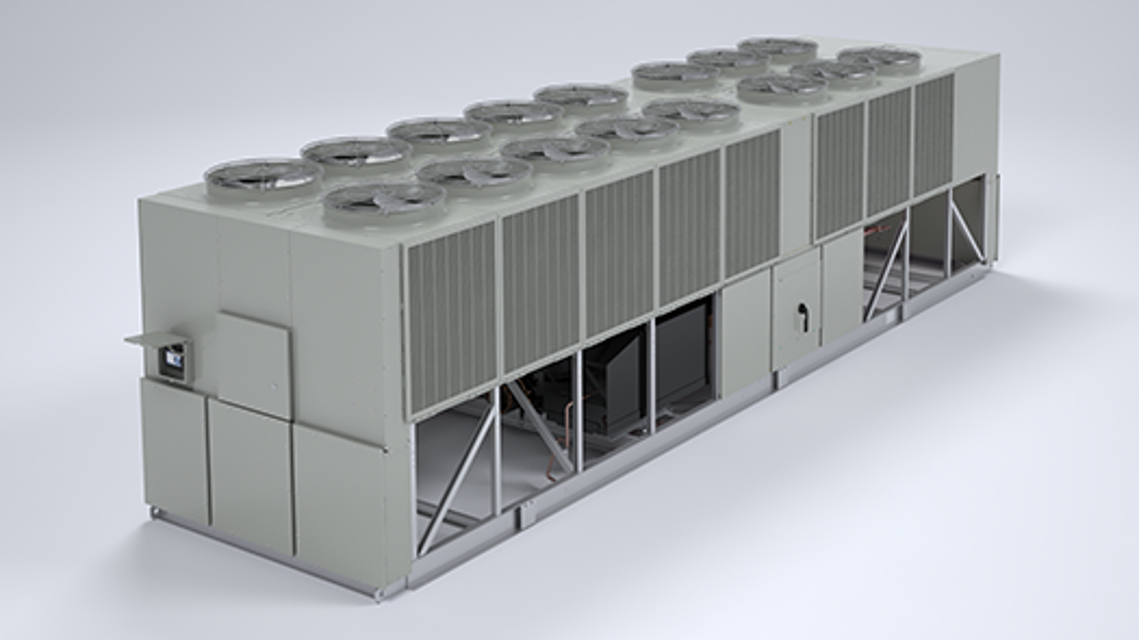

The Trane Series R™ Helical Rotary Chiller RTAC250X is a high-efficiency industrial chiller designed for optimal cooling performance in large facilities. Known for its reliability and advanced technology, this model ensures energy savings and reduced operational costs while maintaining precise temperature control.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC250X

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC250X

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC250X

Integrate maintenance plans directly into your work orders in MaintainX.

Compressor Replacement

Isolate the refrigerant charge outside of the compressor and close all four valves leading to the compressor?

Disconnect power to the chiller. Remove the electrical junction box cover and disconnect the wires?

WARNING: Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to disconnect power before servicing could result in death or serious injury.

Evacuate the compressor through the service fitting provided. If the unit does not have suction service valves, this will include evacuating the low side of the system as well?

Disconnect all four lines attached to the compressor, as well as the junction box. Remove three screws from the bottom of the compressor?

Remove the compressor by sliding it out of the chiller onto a well supported skid or other platform. The compressor is very heavy, so insure that the support is sturdy. A piece of 1x4 lumber placed between the isolators works well to support the compressor feet as it is pulled from the chiller?

Install the new compressor. Reinstall all lines, wires, and screws. Open the service valves, and trim charge as required?

Sign off on the compressor replacement

1 Weekly Series R™ Helical Rotary Chiller Maintenance

While unit is running in stable conditions.

Check MP pressure for evaporator, condenser and intermediate oil.

Observe liquid line sight glass on EXV.

If liquid line sight glass has bubbles measure the subcooling entering the EXV. The subcooling should never be less than 4 °F under any circumstances.

A clear sightglass alone does not mean that the system is properly charged. Also check the rest of the system operating conditions.

Inspect the entire system for unusual conditions and inspect the condenser coils for dirt and debris. If the coils are dirty, refer to coil cleaning.

Sign off on the weekly maintenance

Factory (initial) Oil Charging

Warning: This procedure requires trained personnel with PPE!

Is the unit new or has had all of the oil removed?

Is the isolation valve closed?

Is the oil line shut off valve open?

The oil charging port is a ¼” (6mm) flare fitting with a schrader valve that is on the side of the oil filter housing.

Choose the number of compressor circuits

CAUTION: Use only Trane OIL00048 in the RTAC units to avoid any catastrophic damage to the compressor or unit.

Choose the method of oil charging

Sign off on the oil charging procedure

Evaporator Flow Switch

Specific connection and schematic wiring diagrams are shipped with the unit. Some piping and control schemes, particularly those using a single water pump for both chilled and hot water, must be analyzed to determine how and or if a flow sensing device will provide desired operation.

Follow the manufacturer’s recommendations for selection and installation procedures. General guidelines for flow switch installation are outlined below.

1. Mount the switch upright, with a minimum of 5 pipe diameters of straight hori-zontal run on each side. Do not install close to elbows, orifices or valves.

NOTE: The arrow on the switch must point in the direction of flow.

2. To prevent switch fluttering, remove all air from the water system.

NOTE: The CH530 provides a 6-second time delay after a “loss-of-flow” diagnostic before shutting the unit down. Contact a qualified service representative if nuisance machine shutdowns persist.

3. Adjust the switch to open when water flow falls below the minimum flow rate. Evaporator data is given in the General Information section. Flow switch contacts are closed on proof of water flow.

4. Install a pipe strainer in the entering evaporator water line to protect components from waterborne debris.;

Low Side Charge Isolation

Circuit is off

Suction line isolation valve is closed

Oil return line service valve is closed

Liquid line service valve is closed

EXV is manually opened

Refrigerant moved from the condenser to evaporator using a liquid pump or vacuum pump

NOTE: If a pump is to be used, connect it before closing this valve. This port is only isolated when the valve is back seated. If a vacuum pump is used, then connect it to the discharge line service valve near the oil separator.

Evaporator is large enough to hold all the charge for any unit to below the center-line of the shell

Sign off on the Low Side Charge Isolation procedure

Parts for Trane Series R™ Helical Rotary Chiller RTAC250X

Access the parts list for your equipment in MaintainX.

Isolator

X10140305640

Isolator

X10140305640

Isolator

X10140305640

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX