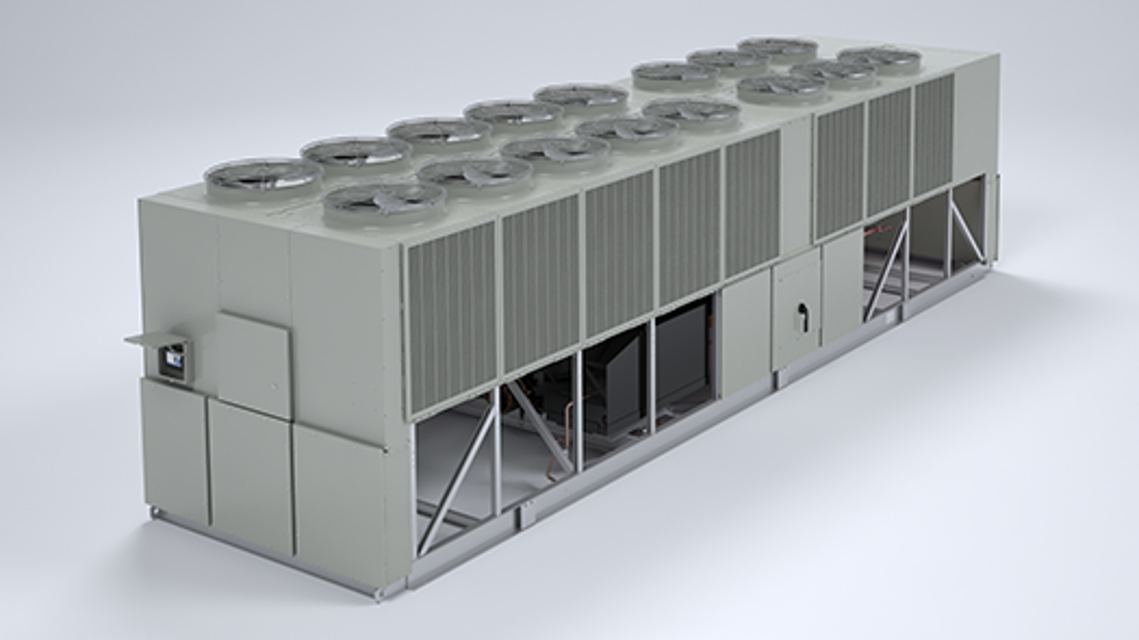

The Trane Series R™ Helical Rotary Chiller RTAC250H is a high-efficiency industrial cooling solution designed for large-scale applications. Known for its reliability and advanced technology, this chiller ensures optimal performance and energy savings in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC250H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC250H

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC250H

Integrate maintenance plans directly into your work orders in MaintainX.

Field Oil Charging

Warning: This procedure requires trained personnel with PPE!

Use the initial charging procedure under the following circumstances:

Select the circumstance

NOTE: This procedure can be followed even with the refrigerant charge isolated in the evaporating section of the unit.

If small quantities of oil were removed to service refrigeration components, such as the evaporator, simply replace the oil that was removed into the serviced component prior to vacuum and recharge of the refrigerant.

If oil was removed from the compressor only to service a compressor or change the oil filter follow this procedure:

If the compressor is a new compressor or has been removed from the system and reworked, add 1 quart (2 lb.) oil to the motor cavity prior to installing the com¬pressor into the chiller.

Compressor installed in the system?

Make sure that the filter shut off valve is closed. Other compressor isolation valves may also be closed depending upon the service that was completed. For example, changing the oil filter would require the compressor to be isolated and pulled into vacuum.

1 Weekly Series R™ Helical Rotary Chiller Maintenance

While unit is running in stable conditions.

Check MP pressure for evaporator, condenser and intermediate oil.

Observe liquid line sight glass on EXV.

If liquid line sight glass has bubbles measure the subcooling entering the EXV. The subcooling should never be less than 4 °F under any circumstances.

A clear sightglass alone does not mean that the system is properly charged. Also check the rest of the system operating conditions.

Inspect the entire system for unusual conditions and inspect the condenser coils for dirt and debris. If the coils are dirty, refer to coil cleaning.

Sign off on the weekly maintenance

Factory (initial) Refrigerant Charging Procedure

Verify that the EXVs are OPEN

Attach vacuum hoses to evaporator service valves (one per circuit)

Open service valves

Attach charging hoses to the charging port on the liquid line filter (one per circuit)

Begin semi-automatic vacuum procedure

When vacuum is complete (indicated), manually isolate the unit from vacuum

Charge unit through the filter housing port per Table 1 - Table 4

When charging is complete, shut evaporator service valve

Disconnect vacuum and charging hoses

Refrigerant and Oil Charge Management

Proper oil and refrigerant charge is essential for proper unit operation, unit perfor-mance, and environmental protection. Only trained and licensed service personnal should service the chiller.

Some symptoms of a refrigerant under-charged unit:

• Low subcooling

• Higher than normal discharge superheat

• Bubbles in EXV sight glass

• Low liquid level diagnostic

• Larger than normal evaporator approach temperatures (leaving water temperature - saturated evaporator temperature)

• Low evaporator refrigerant temperature limit

• Low refrigerant temperature cutout diagnostic

Neoprene Isolator Replacement

Warning: Ensure you are wearing appropriate PPE

Secure the isolators to the mounting surface using the mounting slots in the isolator base plate

Align the mounting holes in the base of the unit with the threaded positioning pins on the top of the isolators

Lower the unit onto the isolators and secure the isolator to the unit with a nut

Enter the isolator deflection (should be 1/4 inch or 6 mm)

Level the unit carefully

Fully tighten the isolator mounting bolts

Sign off on the isolator replacement

Parts for Trane Series R™ Helical Rotary Chiller RTAC250H

Access the parts list for your equipment in MaintainX.

Isolator

X10140305640

Isolator

X10140305640

Isolator

X10140305640

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX