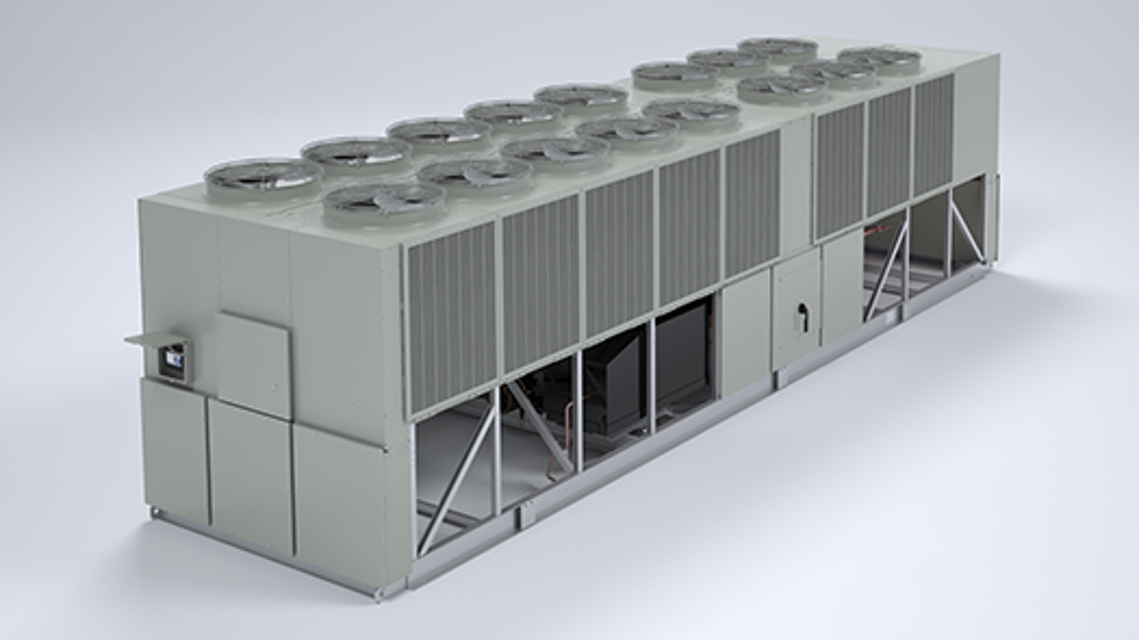

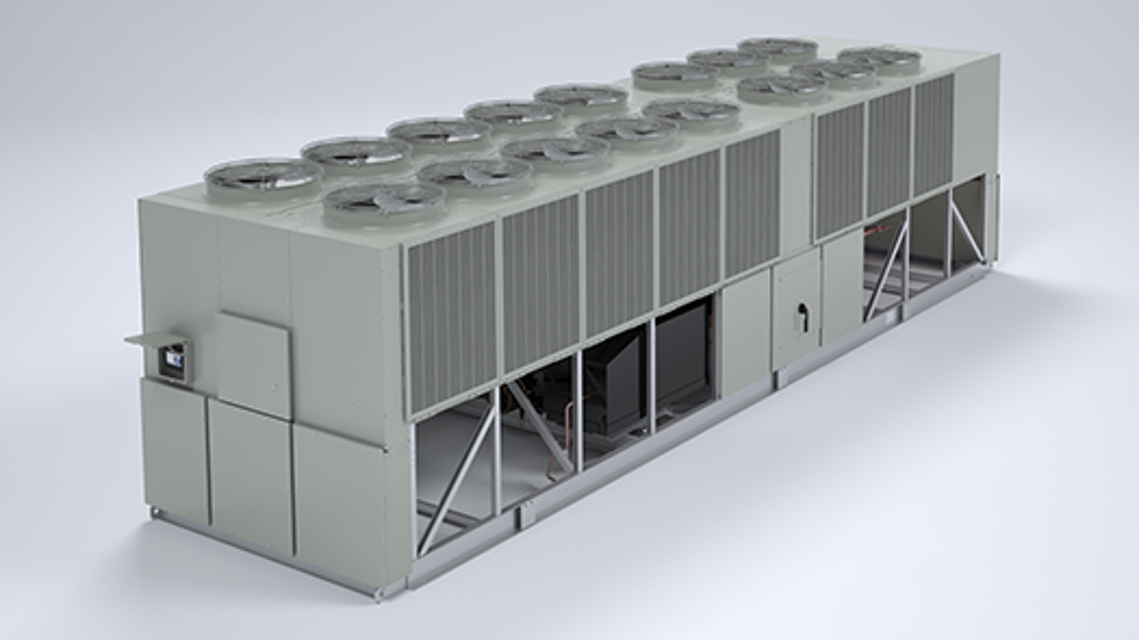

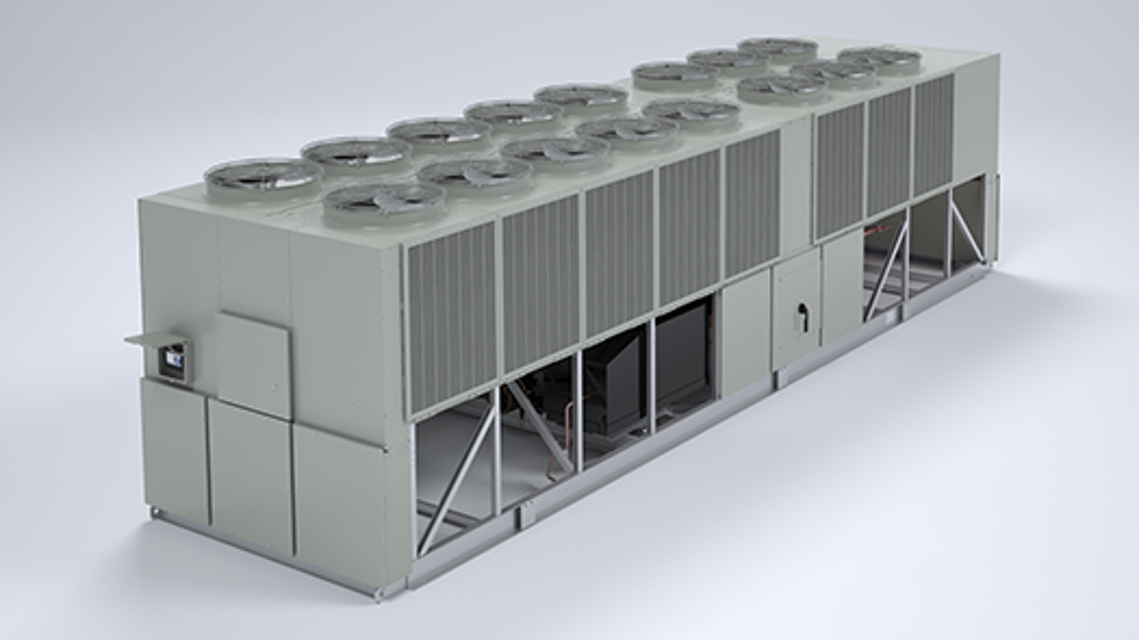

The Trane Series R™ Helical Rotary Chiller RTAC170X is a high-efficiency industrial chiller designed for optimal cooling performance. This advanced model features a helical rotary compressor, ensuring reliable operation and energy savings for large commercial applications. Experience superior temperature control and energy efficiency with Trane's trusted technology.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC170X

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC170X

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC170X

Integrate maintenance plans directly into your work orders in MaintainX.

Clearances

Ensure enough space around the outdoor unit for unrestricted access to all service points.

Refer to submittal drawings for the unit dimensions.

Enter the clearance for compressor service in feet

Is there sufficient clearance for the opening of control panel doors?

Local codes requiring additional clearances will take precedence over these recommendations.

Unobstructed flow of condenser air is essential to maintain chiller capacity and operating efficiency.

Is there sufficient flow of air across the condenser heat transfer surface?

Avoid warm air recirculation and coil starvation.

Is there any evidence of warm air recirculation?

Returning Unit To Running Condition

Open all valves

Manually open EXV for 15 minutes to allow refrigerant to drain to evaporator by gravity (ensure water is flowing in the evaporator prior to opening the EXV)

Let unit sit with heaters on to drive refrigerant out of oil and warm up compressor bearings. Depending upon ambient conditions, this may take up to 24 hours.Ensure the UCM is powered so the pump may be energized if it detects a freeze condition

Once the oil level has returned to normal, the unit can be put back into operation

Sign off on the procedure

Refrigerant and Oil Charge Management

Proper oil and refrigerant charge is essential for proper unit operation, unit perfor-mance, and environmental protection. Only trained and licensed service personnal should service the chiller.

Some symptoms of a refrigerant under-charged unit:

• Low subcooling

• Higher than normal discharge superheat

• Bubbles in EXV sight glass

• Low liquid level diagnostic

• Larger than normal evaporator approach temperatures (leaving water temperature - saturated evaporator temperature)

• Low evaporator refrigerant temperature limit

• Low refrigerant temperature cutout diagnostic

Compressor Replacement

Warning: This procedure requires trained personnel with PPE!

Isolate the refrigerant charge outside of the compressor and close all four valves leading to the compressor?

Disconnect power to the chiller. Remove the electrical junction box cover and disconnect the wires?

WARNING: Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to disconnect power before servicing could result in death or serious injury.

Evacuate the compressor through the service fitting provided. Disconnect all four lines attached to the compressor, as well as the junction box. Remove three screws from the bottom of the compressor?

Remove the compressor by sliding it out of the chiller onto a well supported skid or other platform. The compressor is very heavy, so insure that the support is sturdy. A piece of 1x4 lumber placed between the isolators works well to support the compressor feet as it is pulled from the chiller?

Install the new compressor. Reinstall all lines, wires, and screws. Open the service valves, and trim charge as required?

Sign off on the compressor replacement

Factory (initial) Oil Charging

Warning: This procedure requires trained personnel with PPE!

Is the unit new or has had all of the oil removed?

If the unit is not new or has not had all of the oil removed, report the issues to the maintenance team and stop the procedure

Isolation valves closed?

High side of the system not pressurized?

Oil line shut off valve open?

The oil charging port is a ¼” (6mm) flare fitting with a schrader valve that is on the side of the oil filter housing.

Choose the type of circuit

CAUTION: Use only Trane OIL00048 in the RTAC units to avoid any catastrophic damage to the compressor or unit.

Parts for Trane Series R™ Helical Rotary Chiller RTAC170X

Access the parts list for your equipment in MaintainX.

Isolator

X10140305620

Isolator

X10140305620

Isolator

X10140305620

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX