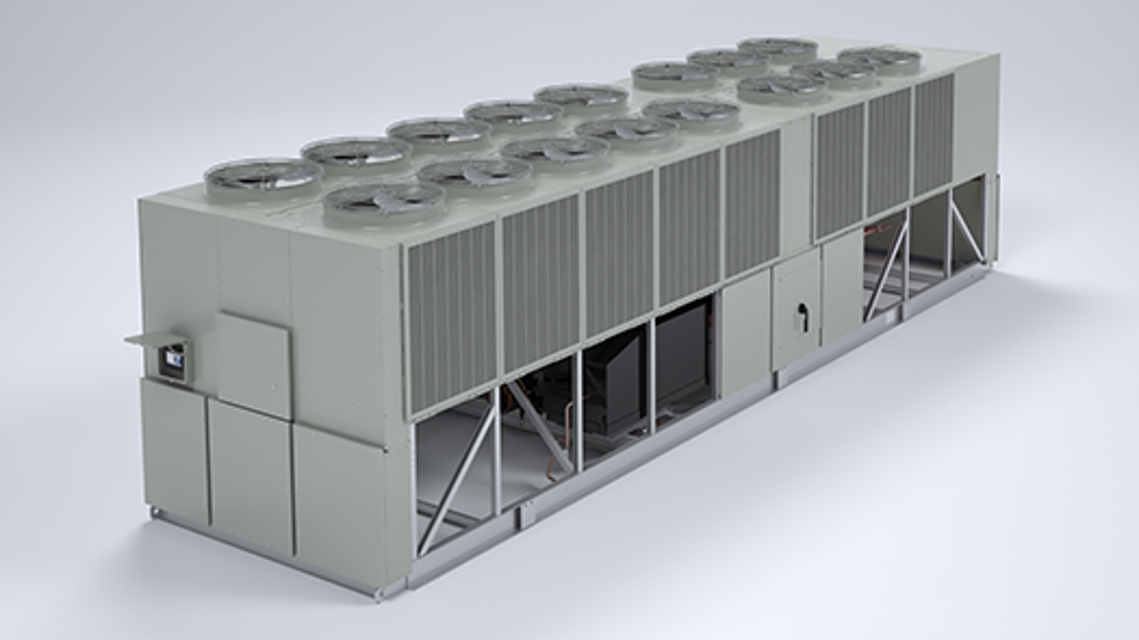

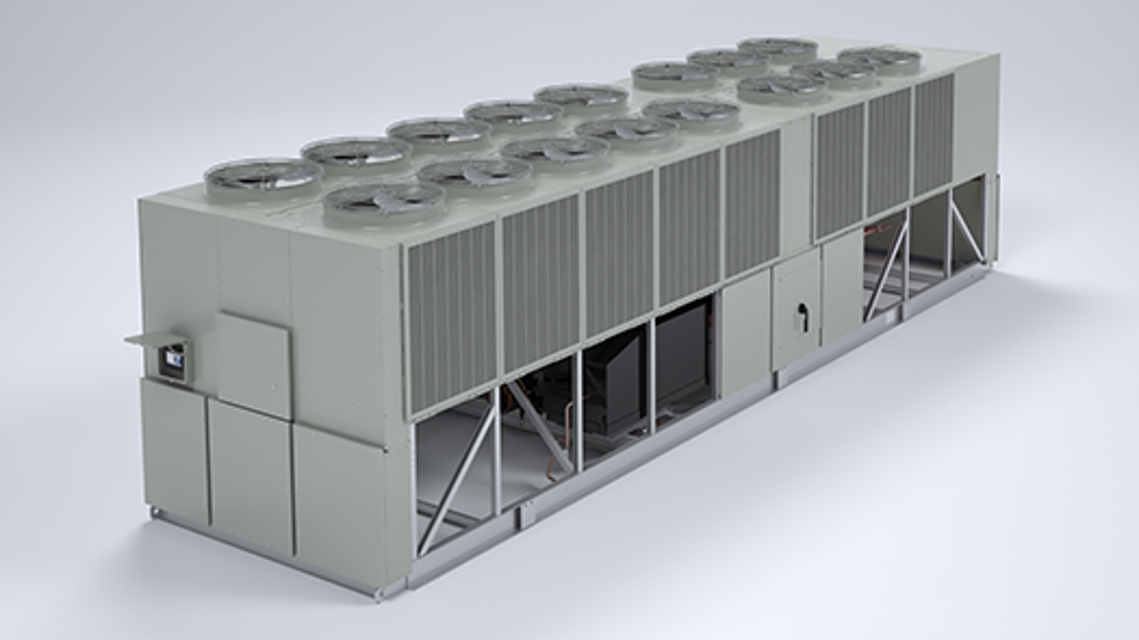

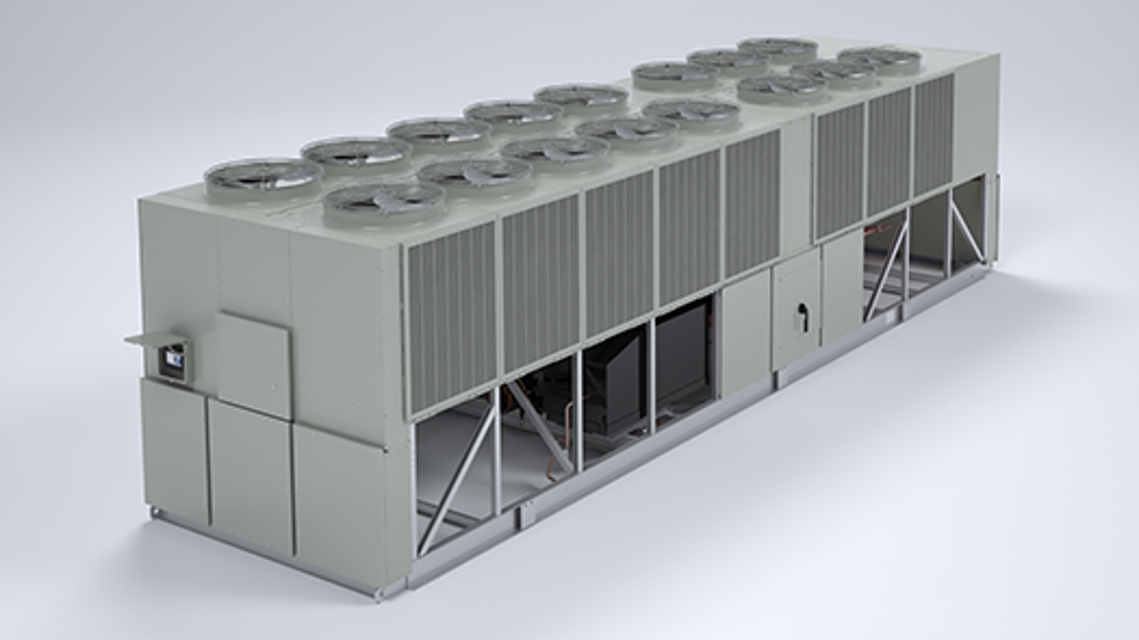

The Trane Series R™ Helical Rotary Chiller RTAC130H is a high-efficiency industrial chiller designed for optimal cooling performance. With advanced technology and robust construction, it ensures reliable operation and energy savings for commercial applications. Ideal for large facilities, this model offers exceptional reliability and ease of maintenance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Series R™ Helical Rotary Chiller RTAC130H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Series R™ Helical Rotary Chiller RTAC130H

Create an account to install this asset package.

Maintenance Plans for Trane Series R™ Helical Rotary Chiller Model RTAC130H

Integrate maintenance plans directly into your work orders in MaintainX.

Evaporator Flow Switch

Follow the manufacturer’s recommendations for selection and installation procedures.

Mount the switch upright, with a minimum of 5 pipe diameters of straight horizontal run on each side.

Switch installed away from elbows, orifices or valves?

The arrow on the switch must point in the direction of flow.

All air removed from the water system to prevent switch fluttering?

The CH530 provides a 6-second time delay after a “loss-of-flow” diagnostic before shutting the unit down.

Switch adjusted to open when water flow falls below the minimum flow rate?

Evaporator data is given in the General Information section. Flow switch contacts are closed on proof of water flow.

Pipe strainer installed in the entering evaporator water line to protect components from waterborne debris?

Refrigerant Filter Replacement

Warning: This procedure requires trained personnel with PPE!

Is the temperature downstream of the filter 8°F (4.4°C) lower than the upstream temperature?

Is the unit undercharged?

Is the EXV closed with the unit off?

Is the liquid line isolation valve closed?

Is the ball valve on oil cooler liquid line closed on units with remote evaporators or oil cooling circuits?

Attach a photo of the hose attached to service port on liquid line filter flange.

Is the refrigerant from liquid line evacuated and stored?

Is the hose removed?

High Side Charge Isolation

Circuit is off

Liquid line service valve is shut

Oil return line service valve is shut

Circuit started with the service tool (access compressor service view in Techview)

Discharge check valve closed after unit trip

Discharge isolation valve is closed

Oil line shut off valve is closed

Refrigerant remainder recovered

NOTE: Remaining vapor can be recovered/stored in the high side of the system. Be certain to follow proper recovery procedures to avoid introduction of non-condensable gases.

Returning Unit To Running Condition

All valves opened

EXV manually opened for 15 minutes

Water flowing in the evaporator prior to opening the EXV

Unit sat with heaters on to drive refrigerant out of oil and warm up compressor bearings

Depending upon ambient conditions, this may take up to 24 hours

UCM is powered so the pump may be energized if it detects a freeze condition

Oil level has returned to normal

Unit put back into operation

1 Monthly Series R™ Helical Rotary Chiller Maintenance

Perform all weekly maintenance procedures

Record the system subcooling

Make any repairs necessary

Parts for Trane Series R™ Helical Rotary Chiller RTAC130H

Access the parts list for your equipment in MaintainX.

Isolator

X10140305620

Isolator

X10140305620

Isolator

X10140305620

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX