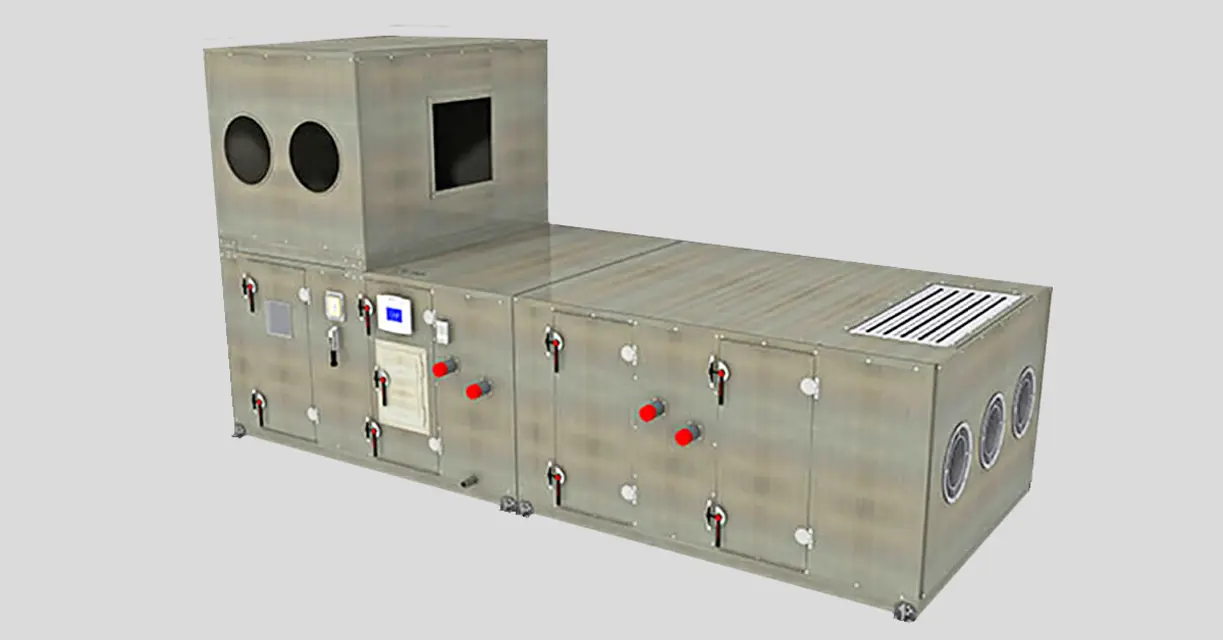

The Trane Modular Air Handler M-Series TEM6A0B24H is a versatile and efficient air handling unit designed for optimal indoor climate control. With advanced features and robust construction, it ensures reliable performance in various commercial applications, making it an ideal choice for HVAC systems.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Modular Air Handler M-Series TEM6A0B24H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Modular Air Handler M-Series TEM6A0B24H

Create an account to install this asset package.

Maintenance Plans for Trane Modular Air Handler Model M-Series TEM6A0B24H

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Air Handler Maintenance

Inspect the unit casing for corrosion. If damage is found, clean and repaint the surface with a rust-resistant primer and vinyl chlorinated lacquer

Clean the fan wheels and fan shaft

Inspect and clean drain pans

Check damper linkages, set screws, and blade adjustment. Clean, but do not lubricate, the nylon damper rod bushings

Clean damper operators

Inspect electrical components and insulation

Inspect wiring for damage

Rotate the fan wheel and check for obstructions in the fan housing. The wheel should not rub on the fan housing. Adjust the center if necessary and tighten wheel set screws to the proper torque

Lubricate motor bearings in accordance with motor manufacturer’s recommendations

3 Monthly Type UW, UU, W, P2, P4, P8, WD, 5D, and 5W Coils Cleaning

Warning: Use care in removing header plugs from Type P2, P4, and P8 coils. Over-torquing may result in twisted tubes

Remove the vent and drain plugs

Blow the coil out as completely as possible with compressed air

Fill and drain the coil several times with full strength glycol so that it mixes thoroughly with the water retained in the coil

Drain the coil out as completely as possible

To ensure no water remains in the coil, do not replace the vent and drain plugs until the coils are put back into service

Sign off on the coil cleaning

1 Yearly Motor Bearings Lubrication

WARNING: Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/ tagout procedure to ensure the power cannot be inadvertently energized. Failure to disconnect power before servicing could result in death or serious injury

Motor bearings are factory-lubricated for normal life

In the case of a double-shielded bearing, the grease provided is that which is in the bearing

To regrease motors without grease fittings, remove the bearing brackets

If the original bearing is to be relubricated, remove the shield opposite the rotor

Flush old grease from bearing with suitable solvent

Lubricate the bearing and add grease to the bearing chamber

The chamber should be three-quarters full of grease

Lubricate the bearing according to the motor manufacturer's recommendations and use the manufacturer-recommended grease

1 Monthly Air Handler Maintenance

WARNING: Hazardous Service Procedures! The maintenance and troubleshooting procedures recommended in this section of the manual could result in exposure to electrical, mechanical or other potential safety hazards. Always refer to the safety warnings provided throughout this manual concerning these procedures.

WARNING: Rotating Components! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/ tagout procedures to ensure the power can not be inadvertently energized. Secure drive sheaves to ensure rotor cannot freewheel.

Clean or replace air filters if clogged or dirty

Coat permanent filters with oil after cleaning

Change bag filters when pressure drop is 1 in. wg

Relubricate fan bearings if necessary

Check and adjust fan belt tension

Sign off on the monthly air handler maintenance

3 Monthly Air Handler Maintenance

Check fan bearing grease line connections. Lines should be tight to the bearings

Check bearing and motor bracket bolt torque and bearing setscrew torque

Align fan and motor sheaves. Tighten sheave set screws to the proper torque

Inspect and clean drain pans

Tighten electrical connections

Inspect coils for dirt build-up

Parts for Trane Modular Air Handler M-Series TEM6A0B24H

Access the parts list for your equipment in MaintainX.

Bearing Bracket Assembly

BRK1756

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Kit With Sensor

X13790452010 SEN-01212

Drive Rod

SHF1709

Bearing Bracket Assembly

BRK1756

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Kit With Sensor

X13790452010 SEN-01212

Drive Rod

SHF1709

Bearing Bracket Assembly

BRK1756

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Kit With Sensor

X13790452010 SEN-01212

Drive Rod

SHF1709

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX