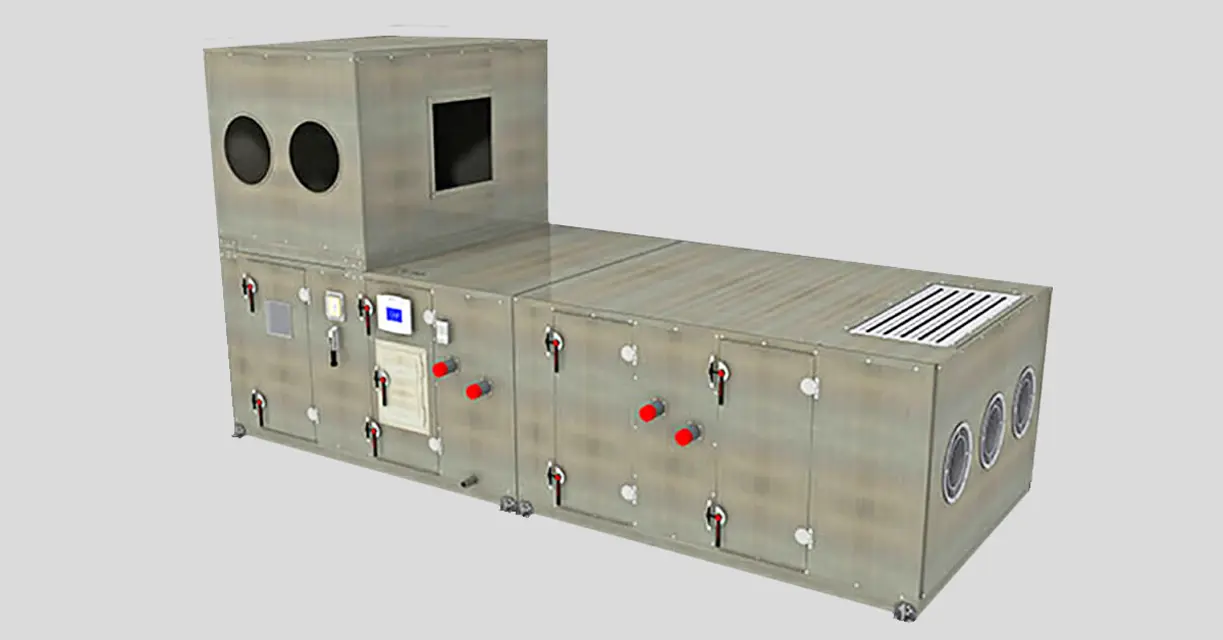

The Trane Modular Air Handler M-Series TEM4B0B24M21SA is designed for efficient air distribution in commercial settings. This versatile unit provides reliable performance and is ideal for various HVAC applications, ensuring optimal indoor air quality and comfort.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trane Modular Air Handler M-Series TEM4B0B24M21SA

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trane Modular Air Handler M-Series TEM4B0B24M21SA

Create an account to install this asset package.

Maintenance Plans for Trane Modular Air Handler Model M-Series TEM4B0B24M21SA

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Air Handler Maintenance

Inspect the unit casing for corrosion. If damage is found, clean and repaint the surface with a rust-resistant primer and vinyl chlorinated lacquer

Clean the fan wheels and fan shaft

Inspect and clean drain pans

Check damper linkages, set screws, and blade adjustment. Clean, but do not lubricate, the nylon damper rod bushings

Clean damper operators

Inspect electrical components and insulation

Inspect wiring for damage

Rotate the fan wheel and check for obstructions in the fan housing. The wheel should not rub on the fan housing. Adjust the center if necessary and tighten wheel set screws to the proper torque

Lubricate motor bearings in accordance with motor manufacturer’s recommendations

3 Monthly Coils Cleaning

Inspect coils for dirt build-up

Disconnect all electrical power to the unit

Use a soft brush to remove loose debris from both sides of the coil

Install a block-off to prevent spray from going through the coil and into a dry section of the unit and/or system ductwork

Mix a high-quality coil cleaning detergent with water according to the manufacturer’s instructions

Place the mixed solution in a garden pump-up sprayer or high-pressure sprayer

Maintain minimum nozzle spray angle of 15 degrees

Spray perpendicular to the coil face

Keep the nozzle at least 6 inches from the coil

Internal Insulation Maintenance

CAUTION: Microbial Growth! Wet interior unit insulation can become an amplification site for microbial growth (mold), which may cause odors and damage to the equipment and building materials.

WARNING: Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/ tagout procedures to ensure the power can not be inadvertently energized.

WARNING: Hazardous Chemicals! Coil cleaning agents can be either acidic or highly alkaline. Handle chemical carefully. Proper handling should include goggles or face shield, chemical resistant gloves, boots, apron or suit as required.

Is the insulation clean and dry?

Is there evidence of contamination in either the wet or dry sections?

Is there microbial growth on a non-porous insulating surface?

Is the drain line open following the cleaning process?

Is the unit dry before putting it back into service?

Are all panels and parts replaced and electrical power restored to the unit?

3 Monthly Coil Winterization

CAUTION: Coil Freezeup! Properly drain and vent coils when not in use. Trane recommends glycol protection in all possible freezing applications. Use a glycol approved for use with commercial cooling and heating systems and copper tube coils. Failure to do so may result in equipment damage

Drain water from the coil

Flush the coil with glycol

Install field-fitted drains and vents

Evacuate air from the water system during startup

Fill the coil with glycol before the heating season begins if draining is questionable because of dirt or scale deposits inside the coil

Enter the Service Model No of Coil

Winterize all coils in a given coil module

Sign off on the coil winterization

1 Monthly Air Handler Maintenance

WARNING: Hazardous Service Procedures! The maintenance and troubleshooting procedures recommended in this section of the manual could result in exposure to electrical, mechanical or other potential safety hazards. Always refer to the safety warnings provided throughout this manual concerning these procedures.

WARNING: Rotating Components! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/ tagout procedures to ensure the power can not be inadvertently energized. Secure drive sheaves to ensure rotor cannot freewheel.

Clean or replace air filters if clogged or dirty

Coat permanent filters with oil after cleaning

Change bag filters when pressure drop is 1 in. wg

Relubricate fan bearings if necessary

Check and adjust fan belt tension

Sign off on the monthly air handler maintenance

Parts for Trane Modular Air Handler M-Series TEM4B0B24M21SA

Access the parts list for your equipment in MaintainX.

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Gasket

GKT 03870

Drive Rod

SHF1709

Center Bracket

BRK01418

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Gasket

GKT 03870

Drive Rod

SHF1709

Center Bracket

BRK01418

Bolt, 1/2-in.

SCR00011

Self-drilling Screws, #10, On 8-in. Centers

SCR01789

Gasket

GKT 03870

Drive Rod

SHF1709

Center Bracket

BRK01418

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX