Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

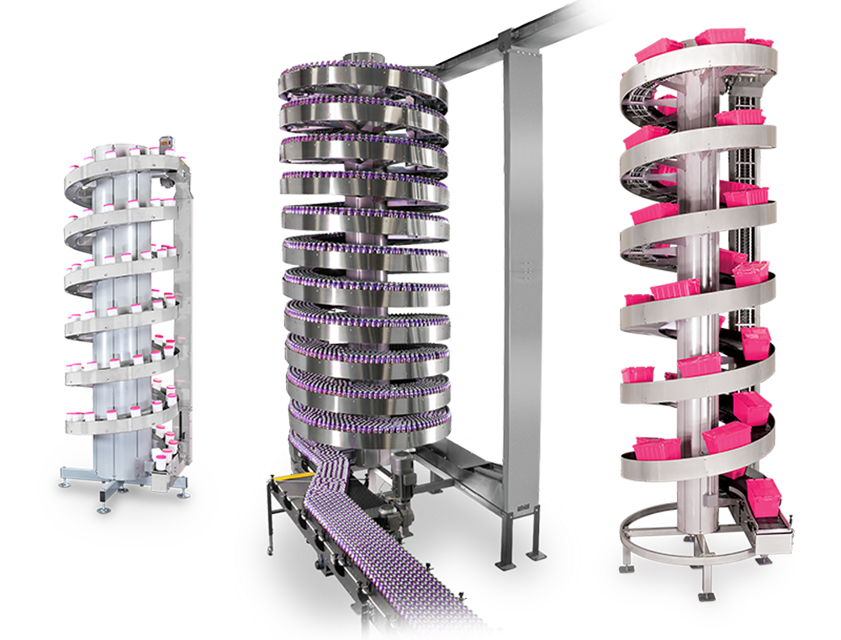

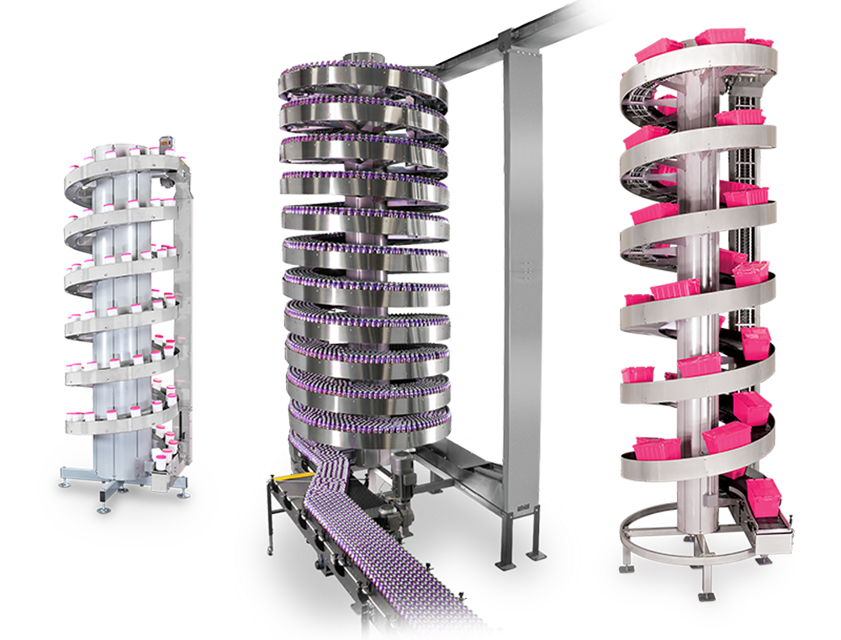

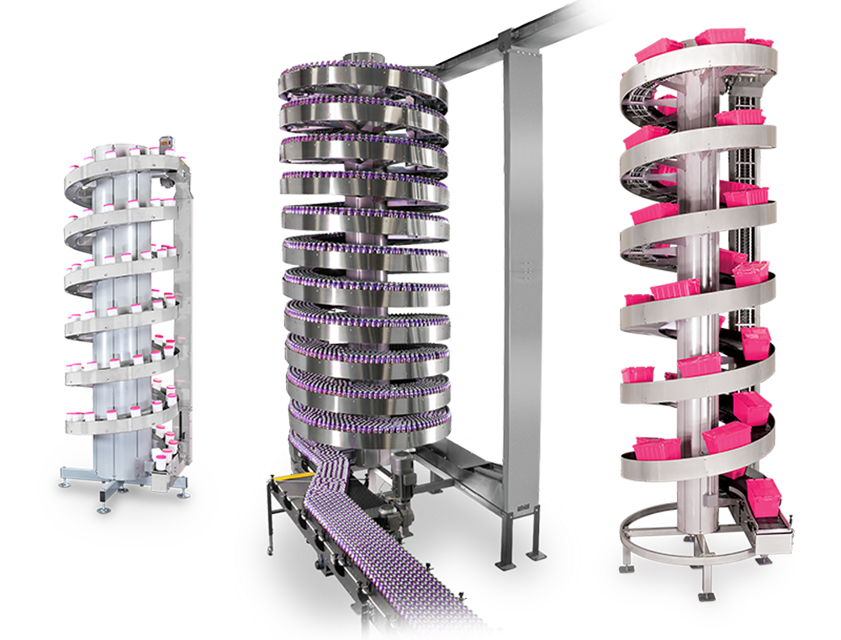

Ryson International Conveyor 1800-650-B3

Create an account to install this asset package.

Maintenance Plans for Ryson International Conveyor Model 1800-650-B3

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Conveyor Check

Transition rollers and holders checked and adjusted

Speed matching checked

Guide rails checked and adjusted

Sign off on the conveyor check

Initial 200 Hours Chain Tension Check

1. Check the chain tension. Shorten the chain when needed. The chain may have to be shortened within the first 200 hours of operation (see the chain shortening instructions in the manual)

• The chain tension bar should operate at an angle between 0o and 6o. The chain needs to be shortened when the tension bar is at or below 0o (horizontal)

• Spirals with spring tensioner - Check the spring compression. The compressed spring should measure 140 mm. The tensioner flag should operate between the red and the green markers

• Spirals with air operated tensioner - Check the tensioner air pressure. For the forward direction (up) the pressure should be set at 15 PSI, and the reverse direction (down) at 20 PSI. Larger units may need higher pressure to achieve proper tension - consult your owners manual;

1 Monthly Conveyor Check

1. Check the chain tensioner and safety circuit for functionality. Fault out the slack chain proximity sensor. The spiral and the infeed conveyors should stop immediately and not automatically restart

2. Check the overload protection device and safety circuit for functionality. Fault out the overload proximity sensor. The spiral and the in-feed conveyors should stop immediately and not automatically restart

3. Check the outfeed jam sensor for functionality. Loads should not back up into a running spiral. The spiral and the infeed conveyors should stop immediately;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX