Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

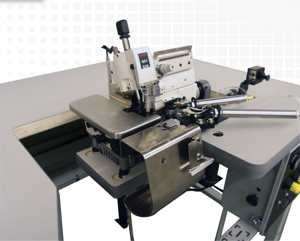

Porter International Flange Machine PFM-4000

Create an account to install this asset package.

Maintenance Plans for Porter International Flange Machine Model PFM-4000

Integrate maintenance plans directly into your work orders in MaintainX.

Top Knife Replacement

Warning: Wear cut-resistant gloves during the procedure

Loosen the bottom knife holder screw

Push the bottom knife holder as far left as possible, and lightly tighten the screw

Remove the top knife screw

Grasp the top knife and remove, pulling in a downward motion

Rotate the handwheel until the top knife clamp is in its lowest position

Insert the new top knife, but do not tighten the top knife screw completely

Set the top knife blade so that its cutting edge overlaps the bottom knife by 0.5 mm to 1.0 mm

After the knife position is correct, tighten the top knife screw securely

6 Monthly Oil Filter Replacement

CAUTION: Replace the oil filter every six months. Clogging of the oil filter can cause insufficient lubrication to the sewing head. Failure of the sewing head components can result.

The oil jet in the oil sight window is restricted or weak

The oil contains foam or debris

The filter shows signs of wear

Follow the instructions under 'Draining the Sewing Head Oil'

Top cover of the sewing head removed

Three screws that secure the oil filter cover removed

Oil cap and the O-ring removed

Old filter replaced with the new one

Top Knife Adjustment

Rotate the handwheel until the knife is in its highest position.

Loosen the top knife screw and move the top knife holder as far left as possible without interference with the presser foot.

Check for interference by manually moving the presser foot up and down. The motion should not cause interference with the top knife holder.

When the setting is correct, tighten the top knife screw.

Sign off on the top knife adjustment

1 Daily Flange Machine Cleaning

Clean the flange machine daily. Use these supplies:

Lint-free rags or shop towels

Small brush

Mild spray cleaner or soap and water

A vacuum cleaner

Compressed air

CAUTION: Do not exceed 30 psi (2 bars) when using compressed air for cleaning purposes.

Dirt and lint accumulation is the most common cause for a poorly operating machine. Lint build-up can destroy certain machine parts. It may be necessary to remove covers to access areas housing some components.

CAUTION: Do not service any of the pneumatic components until the unit is relieved of air pressure. Always wear a mask or turn your face away from the regulator when releasing air pressure. Oil, residue, and debris from the floor may spray with force into the air.

Knives Adjustment

The PFM-4000 Flange Machine has a top knife and a bottom knife. To adjust the I knives, you must set them one at a time in the following order:

1 Set the bottom knife

2 Set the top knife

3 Adjust the bottom knife left or right

4 Adjust the top knife left or right

5 Check the setting of the knives

WARNING: Use extreme caution when handling knives. The blades are extremely sharp. When handling knives, always wear cutresistant gloves.;

Parts for Porter International Flange Machine PFM-4000

Access the parts list for your equipment in MaintainX.

Bottom (Lower) Knife, Right

6Z0386

Flat Head Machine Screw, Fillister

6Z0947

Overedge Looper

6Z1444

Safety Stitch Looper

6Z1532

Needle Set Screw

6Z1631

Bottom (Lower) Knife, Right

6Z0386

Flat Head Machine Screw, Fillister

6Z0947

Overedge Looper

6Z1444

Safety Stitch Looper

6Z1532

Needle Set Screw

6Z1631

Bottom (Lower) Knife, Right

6Z0386

Flat Head Machine Screw, Fillister

6Z0947

Overedge Looper

6Z1444

Safety Stitch Looper

6Z1532

Needle Set Screw

6Z1631

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX