Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

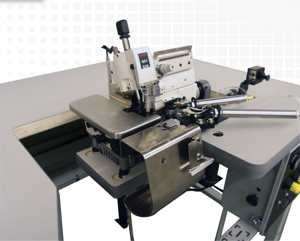

Porter International Flange Machine PFM-1000

Create an account to install this asset package.

Maintenance Plans for Porter International Flange Machine Model PFM-1000

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Oil Change

TO DRAIN OIL:

Remove the machine from its stand and set it on a table

Screw out drain plug (3) and drain oil

Replace drain plug (3)

Upper Knife Replacement

Loosen lower knife holder screw (1) as shown in Fig. 12.

Push the lower knife holder (2) to the left as far as it will go and lightly tighten screw (1).

Remove upper Knife screw (5) and withdraw knife downward.

Turn handwheel until upper knife clamp (4) is at its lowest position.

Replace with new knife but do not tighten screw (5) completely.

Set the blade so that its cutting edge overlaps lower knife by 0.5-1.0mm as shown in Fig. 13. Retighten screw (5) securely.

Loosen screw (1), then the holder (2) will return to position by spring action.

Tighten screw (1).

Sign off on the upper knife replacement

Overedge Left Looper Adjustment

Warning: This procedure requires trained personnel with PPE!

Slide left looper into lever6, making sure it reaches the pin 3 of slot, then tighten screw 4

Slightly loosen screw 6

Turn handwheel by hand until needle bar ascends 3mm from the lowest position.

Move lever 6 so that looper point comes to the scarf of right needle and just touches needle (the clearance 0 - 0.1 mm).

Turn handwheel until looper is at its extreme left position.

Adjust the distance from the centerline of right needle to point of looper to 3mm.

Tighten screw 5 securely.

Sign off on the Overedge Left Looper Adjustment

Oil Maintenance

Warning: Ensure the machine is turned off and cooled down before starting the procedure

Oil sight window removed

Amount of oil poured into reservoir

Oil sight window replaced

Oil level between the two lines on gauge

Sign off on the oil maintenance

Feed Height Adjustment

Warning: Ensure the machine is turned off before starting the procedure

Is the main feed 0.8 - 1.0 mm above the surface of needle plate at its highest position?

If not, follow the steps below

Loosen screws 2 and 4

Adjust feeds 1 and 3 by raising or lowering feeds until proper height is obtained

Tighten screws 2 and 4

Sign off on the feed height adjustment

Parts for Porter International Flange Machine PFM-1000

Access the parts list for your equipment in MaintainX.

Acorn Nut

630300

Adaptor

630301

Preload Spacer

660036

Check Nut

630303

White Spring

630304

Acorn Nut

630300

Adaptor

630301

Preload Spacer

660036

Check Nut

630303

White Spring

630304

Acorn Nut

630300

Adaptor

630301

Preload Spacer

660036

Check Nut

630303

White Spring

630304

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX