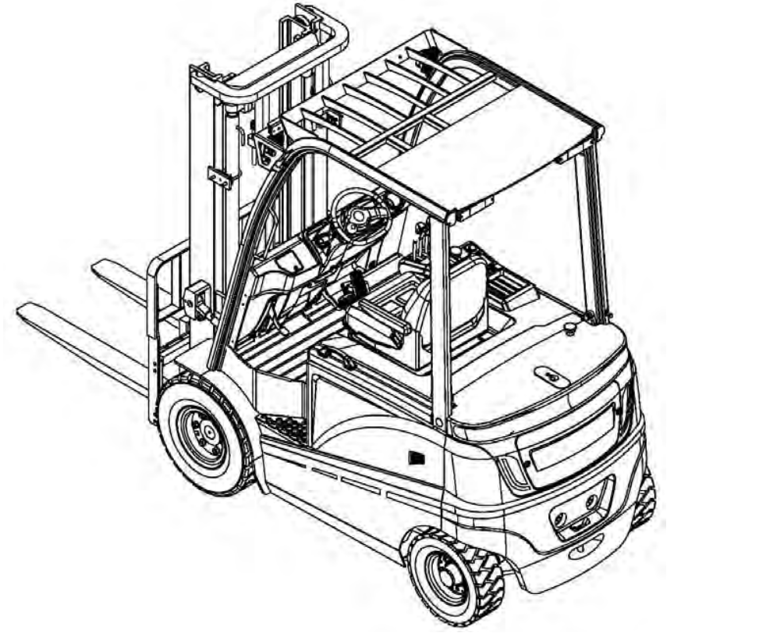

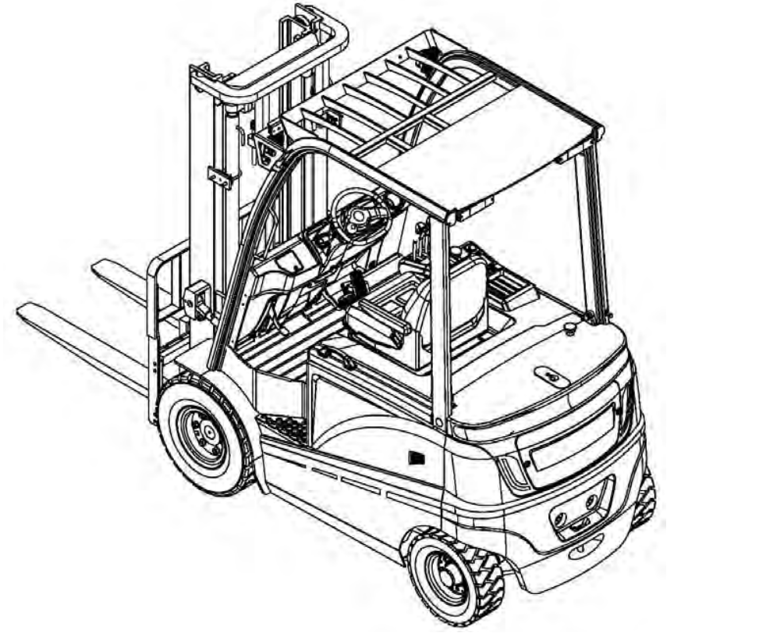

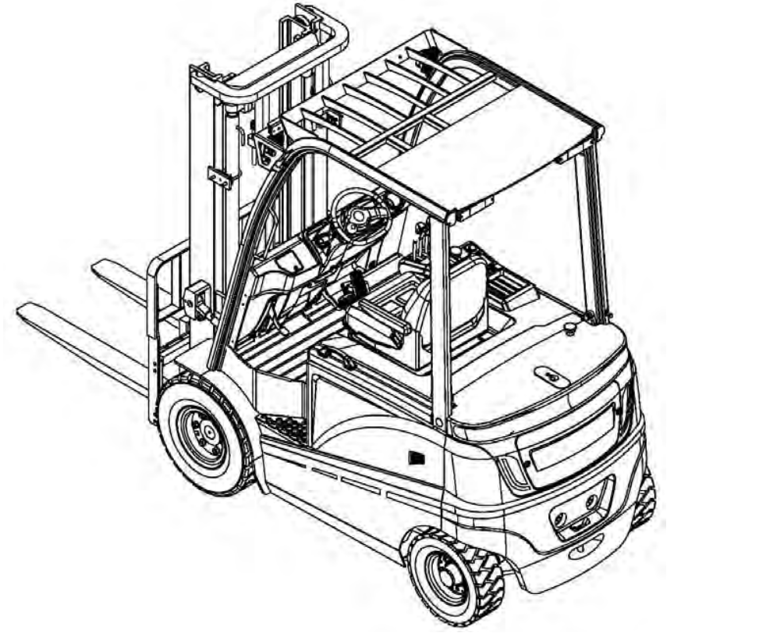

The Noblelift Pallet Truck FE4P77N-177 is a robust and efficient material handling solution designed for industrial applications. This electric pallet truck offers exceptional maneuverability and load capacity, making it ideal for warehouses and distribution centers. Optimize your operations with this reliable asset from Noblelift.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Noblelift Pallet Truck FE4P77N-177

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Noblelift Pallet Truck FE4P77N-177

Create an account to install this asset package.

Maintenance Plans for Noblelift Pallet Truck Model FE4P77N-177

Integrate maintenance plans directly into your work orders in MaintainX.

8 Hourly / 1 Daily Wheel System Check

Check Tyre for wear, cracks or damage

Check Tyre Wheel damage

Check valve block interface with steering leak case

Check seal of connectors

Check steering cylinder operating conditions

Check whether steering cylinder is leaking

Check clearance

Check axis loose

Check radial losse

8 Hourly / 1 Daily Hydraulic System Check

Oil check

Control lever connection check

Control lever operation condition check

Multitandem valve leakage check

Hydraulic pump leakage and noise check

Sign off on the hydraulic system check

600 Hourly / 3 Monthly Controller Check

Check the wear condition of contactors

Check if contactor mechanical movement is good

Check micro switch operation of the pedal is normal

Check if the motor, battery and power unit is a good connection

Check if the malfunction analysis system is normal

Sign off on the controller check

8 Hourly / 1 Daily Lifting System Check

Chain tension state

Deformation

Corrosion damage

Piston rod condition

Piston rod thread condition

Connection condition

Lifting cylinder operating condition

Tilt cylinder operating condition

Lifting cylinder leakage

200 Hourly / 1 Monthly Wheel System Check

Check if there is nails,stone or other foregn items on tire matter

Check if mounting bolts are loose

Check whether the rear axle mounting bolts loose

Check if there is bending, deformation, cracks or damage

Check the junction with the frame bolts loose situation every 200 Hours / 1 Month

Check Electrical connection loose 200 Hours / 1 Month;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX