The Lincoln Electric Wire Feeder LN7 is a robust industrial welding accessory designed for efficient wire feeding in various applications. Known for its reliability and performance, this wire feeder enhances productivity and ensures high-quality welds, making it an essential tool for professional welders.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Wire Feeder LN7

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Wire Feeder LN7

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Wire Feeder Model LN7

Integrate maintenance plans directly into your work orders in MaintainX.

Gun Cable Maintenance

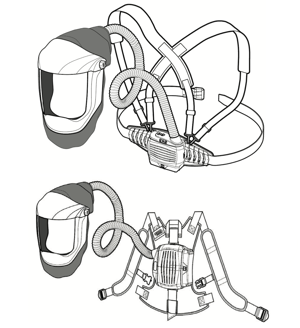

Warning: This maintenance check requires trained personnel with PPE!

Is the gun cable dirty?

If the gun cable is not dirty, stop the procedure

Enter the amount of electrode used

Was the cable removed from the wire feeder?

Was the cable laid out straight on the floor?

Was the contact nozzle tip removed from the gun?

Was the cable gently blown out using an air hose and only partial pressure?

Was the full length of the cable worked by bending it back and forth and then blown out again?

Gun Nozzle Maintenance

Replace worn contact tips as required

On Innershield guns, remove spatter from tip or extension guide after each ten minutes of arc time or as required

Replace worn spring liners in nozzles. The life of the liner can be doubled by rotating liner 180°. The liner can be pulled out the back end of the nozzle by wedging the blade of a small screwdriver in the I.D. and pulling

Inner parts of nozzles can be removed and replaced by removing the internal hollow-lock set screw from the contact tip end of the nozzle with a 5/32 or 3/32 Allen wrench

Sign off on the gun nozzle maintenance

6 Month Automatic Flux Feeding System Cleaning

Turn off the incoming air and release the tank pressure

Remove the coiled aluminum tubing from the bottom of the filter unit

Remove the pinched copper end piece from the end of the aluminum tube

Wash all the material out of the aluminum tube

Clean out the short pinched section

Is the end piece badly corroded?

Replace the corroded end piece with a new one

Loosen the collar on the 2-1/8 inch steel filter tube and take the filter tube off the machine

Wash out the steel filter tube completely

Parts for Lincoln Electric Wire Feeder LN7

Access the parts list for your equipment in MaintainX.

Weld Power Cable

K1842-60

Weld Power Cable

K1841-50

Gun

K206

Gas Solenoid kit

K494

Weld Power Cable

K1842-35

Weld Power Cable

K1842-60

Weld Power Cable

K1841-50

Gun

K206

Gas Solenoid kit

K494

Weld Power Cable

K1842-35

Weld Power Cable

K1842-60

Weld Power Cable

K1841-50

Gun

K206

Gas Solenoid kit

K494

Weld Power Cable

K1842-35

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX