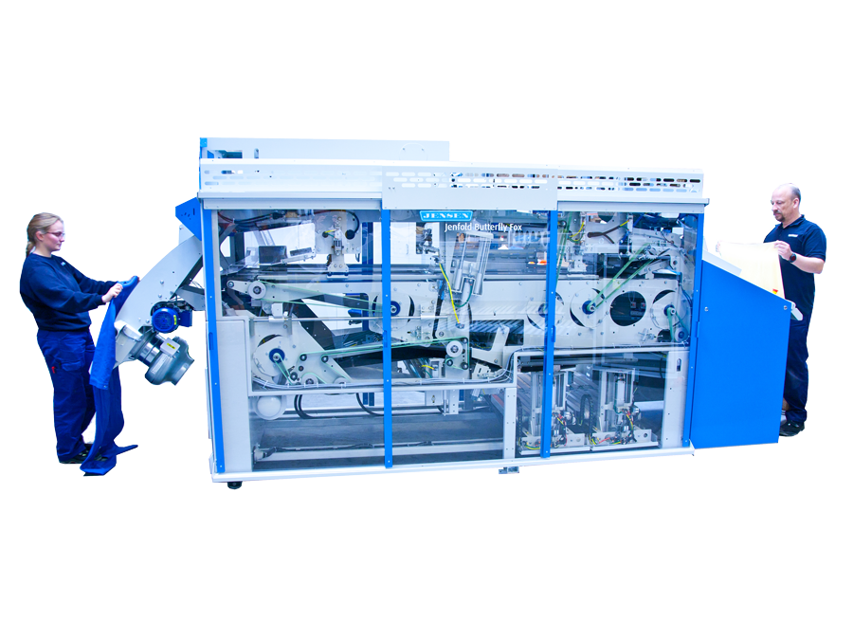

The Jensen Folder Butterfly Fox is a high-performance industrial folding machine designed for efficient paper handling and processing. Known for its reliability and precision, this model is essential for optimizing workflow in various manufacturing environments. Regular maintenance ensures optimal performance and longevity of the equipment.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Jensen Folder Butterfly Fox

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Jensen Folder Butterfly Fox

Create an account to install this asset package.

Maintenance Plans for Jensen Folder Model Butterfly Fox

Integrate maintenance plans directly into your work orders in MaintainX.

40 Hourly / 1 Weekly Electric Motors Cleaning

Warning: Ensure the motors are turned off and disconnected from power before starting the cleaning process.

Are the cooling ventilators of the motors free from dust and threads?

If cleaning with compressed air does not help, proceed to the next step.

Did you dismount and manually clean the ventilator cover?

NOTICE! If the ventilator covers of the motors are blocked, cooling is reduced. This can cause damage to motors and result in a production stop.

Sign off on the electric motors cleaning

160 Hourly / 1 Monthly Folder Check

Warning: Incorrect tension of the belts leads to increased wear.

Check and tighten toothed belts, if necessary

Note: New toothed belts should be checked and readjusted after 10-12 hours of operation.

Check the tape guidance on the rollers below the belts and repair, if necessary

Check the function of the air cylinders. Adjust the throttles and brakes of the cylinders, if necessary

Sign off on the folder check

Flat Belt Adjustment

Warning: Only trained personnel should perform this procedure

Flat belts adjusted from the factory?

Mark the position of the tightening parts before removing the old belts

Indication of how tight the new belts should be

Sign off on the belt adjustment

40 Hourly / 1 Weekly Folder Cleaning

WARNING! Risk of fire! Remove dry dust from all mechanical and manual handling of linen areas of the machine and its close surroundings, as an accumulation of such increases the risk of fire in the machine

Clean dust and lint from cylinder piston rods

If air cylinders are lubrication free, did you add a few drops of oil on the cylinder piston rods?

Wipe off dust and lint thoroughly behind cover plates and under the machine

Clean dust and lint from the air filter of the cooling ventilator on the electric cabinet

Remove dry dust from all mechanical and manual handling of linen areas of the machine and its close surroundings

Check that the machine has not moved from its position, i. e. that the inlet of the machine has not moved towards the ironer inlet conveyor, that it is straight and level, and stands at a proper distance from the ironer

Sign off on the cleaning procedure

1000 Hourly / 6 Monthly Folder Maintenance

Check bearings acoustically by starting the machine and letting it run at idle speed

Grease bearings and lubricating nipples

NOTICE! Immediately change defective bearings, as these can result in serious interruptions of the production

Check that all screws and bolts are tightened

Sign off on the folder maintenance

Parts for Jensen Folder Butterfly Fox

Access the parts list for your equipment in MaintainX.

Pulley, Ø40.5, 60Hz

426C4623

Roller Ø120 L=1000mm

426D0520

Flange Bushing

5098129

Tightening Device

5098048

Journal Complete

80480015

Pulley, Ø40.5, 60Hz

426C4623

Roller Ø120 L=1000mm

426D0520

Flange Bushing

5098129

Tightening Device

5098048

Journal Complete

80480015

Pulley, Ø40.5, 60Hz

426C4623

Roller Ø120 L=1000mm

426D0520

Flange Bushing

5098129

Tightening Device

5098048

Journal Complete

80480015

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX