Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

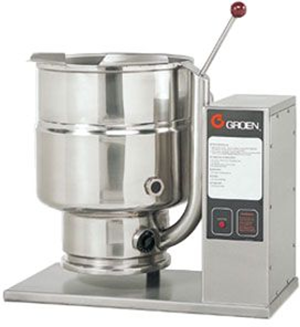

Manual for Groen Steam Jacketed Kettle TDBC-20

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Groen Steam Jacketed Kettle TDBC-20

Create an account to install this asset package.

Maintenance Plans for Groen Steam Jacketed Kettle Model TDBC-20

Integrate maintenance plans directly into your work orders in MaintainX.

Jacket Vacuum Service

NOTE! When the kettle is cold, a positive pressure reading or a reading around zero on the pressure/vacuum gauge indicates the presence of air in the jacket. Air in the jacket slows down the heating of the kettle.

Is there water or product in the kettle?

Enter the pressure/vacuum gauge reading

Did the pressure/vacuum gauge reach a positive pressure reading of five PSI?

Release the trapped air and steam by pulling up on the safety valve for about 1 second.

Did you release the trapped air and steam?

Repeat the previous step, then let the chain snap back into the closed position.

Sign off on the jacket vacuum service

1 Daily Steam Jacketed Kettle Cleaning

WARNING! KEEP WATER AND SOLUTIONS AWAY FROM CONTROLS AND ELECTRICAL EQUIPMENT. NEVER SPRAY THE SUPPORT HOUSING OR ELECTRICAL CONNECTIONS

CAUTION! MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES, AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN. WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD, AND PROTECTIVE CLOTHING. READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER CAREFULLY

Clean food-contact surfaces as soon as possible after use. If the unit is in continuous use, thoroughly clean and sanitize the interior and exterior at least once every 12 hours

WARNING! AVOID ANY DIRECT CONTACT WITH HOT SURFACES. DIRECT SKIN CONTACT COULD RESULT IN SEVERE BURNS

Scrape and flush out food residues. Be careful not to scratch the kettle with metal implements

Prepare a hot solution of the detergent/ cleaning compound as instructed by the supplier. Clean the unit thoroughly. A cloth moistened with cleaning solution can be used to clean controls, housings, and electrical conduits

Rinse the kettle thoroughly with hot water, then drain completely

As part of the daily cleaning program, clean soiled external and internal surfaces. Remember to check the sides of the unit and control housing

To remove stuck materials, use a brush, sponge, cloth, plastic or rubber scraper, or plastic wool with the cleaning solution. To reduce effort required in washing, let the detergent solution sit in the kettle and soak into the residue. Do NOT use abrasive materials or metal tools that might scratch the surface. Scratches make the surface harder to clean and provide places for bacteria to grow. Do NOT use steel wool, which may leave particles in the surface and cause eventual corrosion and pitting

1 Daily Steam Jacketed Kettle Check

NOTICE: Contact Groen or an authorized Groen representative when repairs are required

Pressure/vacuum gauge reading

Is the pressure/vacuum gauge showing a vacuum of 20 to 30 inches when the kettle is cold?

If the gauge does not show a vacuum of 20 to 30 inches, see 'Jacket Vacuum' on page 14

Is the jacket water level above mid point of the round sight glass?

If the water level is low, see 'Jacket Filling and Water Treatment' on page 14

6 Monthly Steam Jacketed Kettle Lubrication

NOTICE: Contact Groen or an authorized Groen representative when repairs are required

Grease the two trunnion bearings

Remove the access panels from the support housing

Check the mounting bolts for the trunnion bearings and tilt switch for tightness

Lubricate the gear housing on the crank-tilt models

Add grease through the Zerk fittings on the gear housing until you see grease flow out of the bearings around the trunnion shaft

Place a liberal amount of grease on the gear to cover the arc that is in contact with the worm gear

Reassemble access panels to support housing

Ensure electrical wiring is securely connected and in good condition

2 Weekly Safety Valve Test

NOTICE: Contact Groen or an authorized Groen representative when repairs are required

Test the safety valve at least twice each month

Test the valve with the kettle operating at 15 psi (105 kPa), by pulling up the test chain for at least five seconds

Then release the chain and let the valve snap shut

If the valve does not activate, (there is no evidence of discharge, or the valve leaks) stop using the kettle immediately and contact a qualified Groen service representative

Sign off on the safety valve test

Parts for Groen Steam Jacketed Kettle TDBC-20

Access the parts list for your equipment in MaintainX.

Cover, Thermostat

114830

Knob, Thermostat

122054

Nut, hex 1/2-13 ss

005603

Washer lock 1/2 ss

005657

Weldment, Pedestal - TDB

122388

Cover, Thermostat

114830

Knob, Thermostat

122054

Nut, hex 1/2-13 ss

005603

Washer lock 1/2 ss

005657

Weldment, Pedestal - TDB

122388

Cover, Thermostat

114830

Knob, Thermostat

122054

Nut, hex 1/2-13 ss

005603

Washer lock 1/2 ss

005657

Weldment, Pedestal - TDB

122388

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX