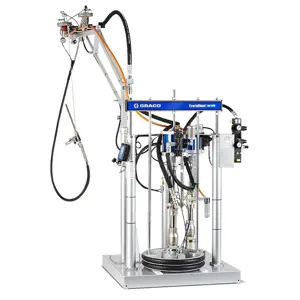

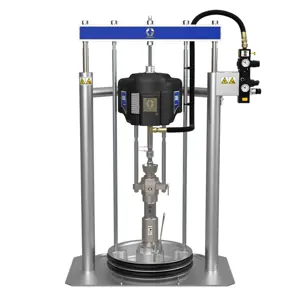

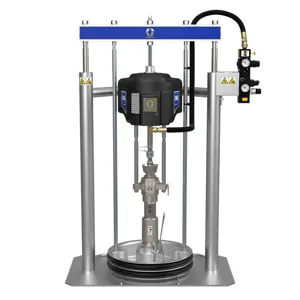

The Graco Spray Package K70MH2 is a high-performance industrial spray system designed for efficient fluid application. Known for its reliability and precision, this OEM asset is ideal for various coating and painting tasks in industrial settings, ensuring optimal results and reduced downtime.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Spray Package K70MH2

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Spray Package K70MH2

Create an account to install this asset package.

Maintenance Plans for Graco Spray Package Model K70MH2

Integrate maintenance plans directly into your work orders in MaintainX.

Spray Package Maintenance

Preventative Maintenance Schedule

Record when and what kind of maintenance is needed

Establish a regular schedule for checking your system

Corrosion Protection

Flush the pump before the fluid dries on the displacement rod

Was water or water-based fluid left in the pump overnight?

NOTICE: Leaving water or water-based fluid in the pump overnight can cause the equipment to rust or corrode.

If you are pumping water-based fluid, flush with water first, then with a rust inhibitor such as mineral spirits.

Relieve pressure, but leave rust inhibitor in pump to protect parts from corrosion.

1 Daily Spray Package Maintenance

Preventative Maintenance Schedule

The operating conditions of your particular system determine how often maintenance is required. Establish a preventative maintenance schedule by recording when and what kind of maintenance is needed, and then determine a regular schedule for checking your system.

Daily Maintenance

NOTE: For overnight shutdown, stop pump at bottom of its stroke to prevent fluid from drying on exposed displacement rod and damaging throat packings. Perform the Prime procedure on page 17.

Perform the Flush procedure

Perform Pressure Relief Procedure

Remove tip and tip guard from gun

If desired, remove fluid filter. Reinstall filter cap after removing fluid filter

Place suction tube in a compatible solvent

Cart Maintenance

Preventative Maintenance Schedule

The operating conditions of your particular system determine how often maintenance is required. Establish a preventative maintenance schedule by recording when and what kind of maintenance is needed, and then determine a regular schedule for checking your system.

Cart Maintenance

Periodically lubricate the axle between points AXA and AXB with lightweight oil.

Keep the cart clean by wiping up spills daily, using a compatible solvent. ;

Parts for Graco Spray Package K70MH2

Access the parts list for your equipment in MaintainX.

Datatrak Kit

24X550

Air Motor

XL65D0

TSL, Fluid

206994

Pump Package

P70HM2

Kit, Pump Filter (60 mesh)

17V371

Datatrak Kit

24X550

Air Motor

XL65D0

TSL, Fluid

206994

Pump Package

P70HM2

Kit, Pump Filter (60 mesh)

17V371

Datatrak Kit

24X550

Air Motor

XL65D0

TSL, Fluid

206994

Pump Package

P70HM2

Kit, Pump Filter (60 mesh)

17V371

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX