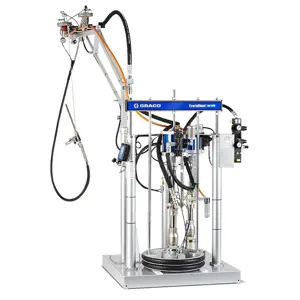

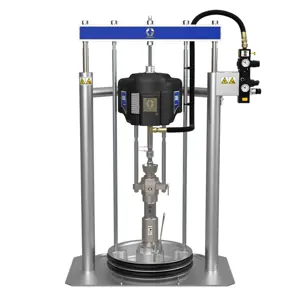

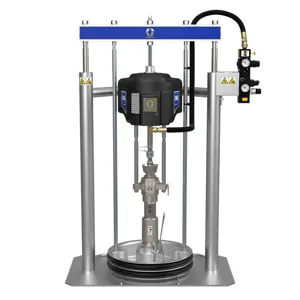

The Graco Proportioner 282000 is a high-performance industrial asset designed for precise fluid dispensing. This versatile proportioner is ideal for various applications, ensuring accurate mixing and application of materials. Regular maintenance and quality spare parts are essential for optimal performance and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Proportioner 282000

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Proportioner 282000

Create an account to install this asset package.

Maintenance Plans for Graco Proportioner Model 282000

Integrate maintenance plans directly into your work orders in MaintainX.

Proportioner Cleaning

Ensure all equipment is grounded. See Grounding, page 20.

Ensure the area where the system will be cleaned is well ventilated and remove all ignition sources.

Turn off all heaters and allow equipment to cool.

Flush mixed material. See Flush Mixed Material, page 30.

Relieve pressure. See Pressure Relief Procedure, page 24.

Shutdown the sprayer and turn off all power. See Shutdown, page 33.

Upload a photo of the external surfaces before cleaning

Clean the external surfaces only using a rag soaked in solvent that is compatible with the spray material and surfaces being cleaned.

Allow enough time for the solvent to dry before using the system.

1 Weekly Proportioner Maintenance

Filters

Once a week check, clean, and replace (if needed) the following filters:

• Both pump filters; see lower manual for instructions.

• Main air inlet manifold filter

1. Close the main air shutoff valve on the air supply line and on the system. Depressurize the air line.

2. Unscrew the serrated ring on filter bowl (210).

3. Remove and replace the filter element (210a). See Air Controls, 258983, page 58.

• Spray gun handle filter; see spray gun manual.

Seals

Mix Ratio Adjustment

NOTE: Only Xtreme XP lower pumps come with a rod coupling.

Check the Varying Parts table on page 57 for the correct pump sizes.

Remove and replace pump. See page 38.

Adjust the position of the air motor. See page 22.

If changing from one type of XP system to another (for example - changing from XP35 to XP70 or from XP70 to XP35): remove the existing over pressure relief valves (302) and install the correct valves for the new system type. See Replace Over Pressure Relief Valves on page 41.

Change air pressure relief valve as required, depending on ratio. See air relief valve (64) in tables starting on page 50.

Sign off on the mix ratio adjustment

Parts for Graco Proportioner 282000

Access the parts list for your equipment in MaintainX.

Kit, Mixer Element, 25 Pack

248927

Fitting, Elbow, 60 Degree

15M987

Coupling

162024

Label, Warning, Fire And Explosion Hazard

16F359

Bolt, U-Bolt, 3/8-16, 1.00 Dia

124293

Kit, Mixer Element, 25 Pack

248927

Fitting, Elbow, 60 Degree

15M987

Coupling

162024

Label, Warning, Fire And Explosion Hazard

16F359

Bolt, U-Bolt, 3/8-16, 1.00 Dia

124293

Kit, Mixer Element, 25 Pack

248927

Fitting, Elbow, 60 Degree

15M987

Coupling

162024

Label, Warning, Fire And Explosion Hazard

16F359

Bolt, U-Bolt, 3/8-16, 1.00 Dia

124293

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX