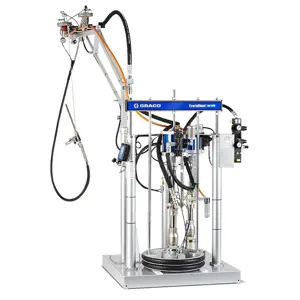

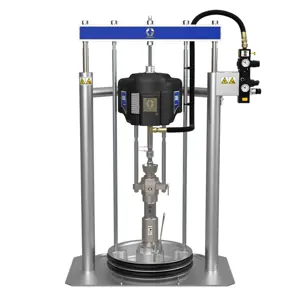

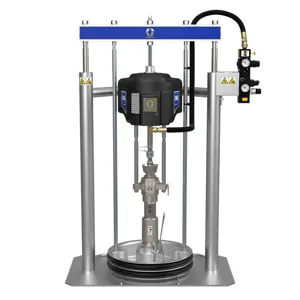

The Graco Proportioner 253402 is a high-performance industrial equipment designed for precise fluid dispensing. This model is ideal for applications requiring accurate mixing and application of materials, ensuring efficiency and reliability in various manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Proportioner 253402

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Proportioner 253402

Create an account to install this asset package.

Maintenance Plans for Graco Proportioner Model 253402

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Proportioner Check

Check hoses and couplings

Check gun resistance

Check equipment

Inspect Inlet Fluid Strainer Screens

Clean the A-side screen

Check the condition of the ISO pump lubricant

Upload a photo of the equipment after check

Sign off on the daily proportioner check

1 Yearly / 1000 Hourly Hydraulic Fluid and Filter Replacement

Change Hydraulic Fluid and Filter

1. Pressure Relief Procedure:

1.1. Relieve pressure in gun and perform gun shutdown procedure. See gun manual.

1.2. Engage gun piston safety lock.

1.3. Close gun fluid manifold valves A and B.

1.4. Shut off feed pumps and agitator, if used.

1.5. Turn PRESSURE RELIEF/SPRAY valves SA, SB to PRESSURE RELIEF/CIRCULATION. Route fluid to waste containers or supply tanks. Ensure gauges drop to 0.

1.6. Disconnect gun air line and remove gun fluid manifold.

2. Allow hydraulic fluid to cool.

1 Monthly Lubricant Replacement

To change pump lubricant:

1. Pressure Relief Procedure:

1.1. Relieve pressure in gun and perform gun shutdown procedure. See gun manual.

1.2. Engage gun piston safety lock.

1.3. Close gun fluid manifold valves A and B.

1.4. Shut off feed pumps and agitator, if used.

1.5. Turn PRESSURE RELIEF/SPRAY valves SA, SB to PRESSURE RELIEF/CIRCULATION. Route fluid to waste containers or supply tanks. Ensure gauges drop to 0.

1.6. Disconnect gun air line and remove gun fluid manifold.

2. Lift the lubricant reservoir LR out of the bracket RB and remove the container from the cap. Holding the cap over a suitable container, remove the check valve and allow the lubricant to drain. Reattach the check valve to the inlet hose. See FIG. 15.

Initial 3 Months / 250 Hours Hydraulic Fluid and Filter Replacement

Change break-in oil in a new unit after first 250 hours of operation or within 3 months, whichever comes first.

Change Hydraulic Fluid and Filter

1. Pressure Relief Procedure:

1.1. Relieve pressure in gun and perform gun shutdown procedure. See gun manual.

1.2. Engage gun piston safety lock.

1.3. Close gun fluid manifold valves A and B.

1.4. Shut off feed pumps and agitator, if used.

1.5. Turn PRESSURE RELIEF/SPRAY valves SA, SB to PRESSURE RELIEF/CIRCULATION. Route fluid to waste containers or supply tanks. Ensure gauges drop to 0.

1.6. Disconnect gun air line and remove gun fluid manifold.

Parts for Graco Proportioner 253402

Access the parts list for your equipment in MaintainX.

80 Mesh Filter (Optional)

255082

20 Mesh Filter (Standard)

180199

80 Mesh Filter (Optional)

255083

Thermal Compound

110009

80 Mesh Filter (Optional)

255082

20 Mesh Filter (Standard)

180199

80 Mesh Filter (Optional)

255083

Thermal Compound

110009

80 Mesh Filter (Optional)

255082

20 Mesh Filter (Standard)

180199

80 Mesh Filter (Optional)

255083

Thermal Compound

110009

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX