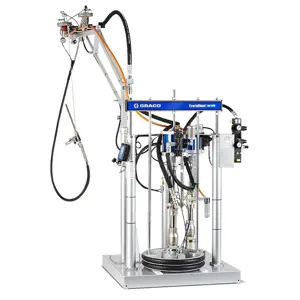

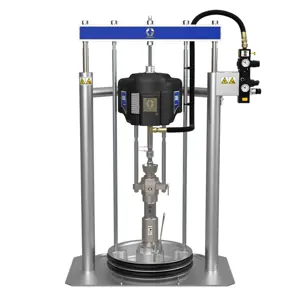

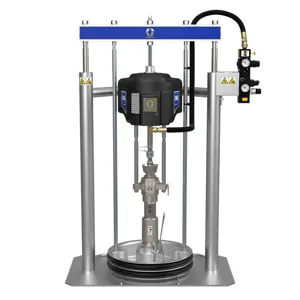

The Graco Preset Meter 24U952 is an advanced industrial flow measurement device designed for precise fluid dispensing. Known for its reliability and accuracy, this OEM asset is essential for various applications in manufacturing and processing environments. Optimize your operations with the Graco 24U952 for enhanced productivity and efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Preset Meter 24U952

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Preset Meter 24U952

Create an account to install this asset package.

Maintenance Plans for Graco Preset Meter Model 24U952

Integrate maintenance plans directly into your work orders in MaintainX.

Fluid Section Maintenance

Warning: Do not disassemble the fluid and counting sections simultaneously. Confirm that the fluid section is fully assembled before removing the counting section.

Pressure Relief Procedure

Turn off the power supply to the pump, or close the upstream master air valve E.

Open all fluid shut off valves J and L in the system.

Trigger the meter N into a waste container to relieve pressure.

Open the fluid drain valves and leave open until ready to pressurize the system.

Close the fluid shut off valve L.

Remove the nozzle 101 and the extension 102.

Turn the meter cap 17 counter-clockwise to unscrew and remove it from the meter housing.

Preset Meter Maintenance

Disassembly

NOTE: Do not disassemble the fluid and counting sections simultaneously. Confirm that the fluid section is fully assembled before removing the counting section.

1. Follow Pressure Relief Procedure, page 7

2. Remove the cover 44 and the small retaining ring 43 See Fig. 26

3. Remove the needle pointer 41, the springs 39, and the pins 40 See Fig. 27

4. Remove the large retaining clip 38, and then the face plate panel 37 See Fig. 28

5. Use a 2 mm hex key to remove the gear setscrew 33 Remove the gears 32, 34 See Fig. 29

6. Remove the entire counter assembly 31 See Fig. 30

Reassembly

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX