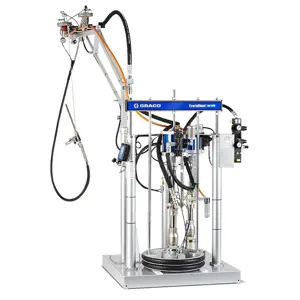

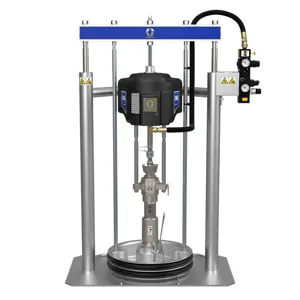

The Graco Plural Component Mixer 233856 is a high-performance industrial mixing solution designed for precise application of two-component materials. Known for its reliability and efficiency, this mixer is essential for various manufacturing processes requiring accurate mixing ratios and consistent output.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Plural Component Mixer 233856

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Plural Component Mixer 233856

Create an account to install this asset package.

Maintenance Plans for Graco Plural Component Mixer Model 233856

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Bearings Replacement

Turbine Alternator

Replace bearings every 2000 hours

Alternator Repair

Turbine Alternator Repair Kit 223688 is available to replace turbine bearings.

1. Remove User Interface cover. See page 17

2. Disconnect power supply wires (P). Fig. 13

3. Disconnect two air lines (310) from alternator (304). Fig. 14

4. Remove top nut (305) and loosen bottom nut. Slide alternator up and off bottom nut

5. Remove four screws (304d) to separate alternator housings. Fig. 15

1 Daily Plural Component Mixer Check

Check equipment daily. Repair or replace worn or damaged parts immediately.

Check air filters daily. Drain and clean as necessary.

Replacing Air Filter Element

There are 2 air filters on the unit: the 5 micron air manifold filter (518) and 40 micron pump air filter (8). Check filters daily and replace element as needed.

WARNING: Removing the bowl of a pressurized air filter could cause serious injury. Do not service air filter until air line is depressurized.

Close main air shutoff valve on air supply line and on unit. Depressurize air line.

Remove air manifold cover (42). Fig. 3

Unscrew filter bowl. Fig. 4

Remove and replace element

Metering Valve Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Enter the torque applied to packing nuts of metering valves A and B in in/lbs

Check packing nut tightness after first hour of operation

Check packing nut tightness after 24 hours

Check packing nut tightness when TSL discolors or seeps over packing nut

Check packing nut tightness whenever unit is transported

Did you replace metering valve packings?

Sign off on the metering valve maintenance

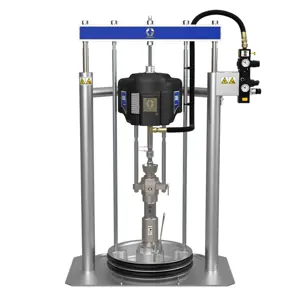

Parts for Graco Plural Component Mixer 233856

Access the parts list for your equipment in MaintainX.

Pump

249275

Pump

249275

Pump

249275

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX