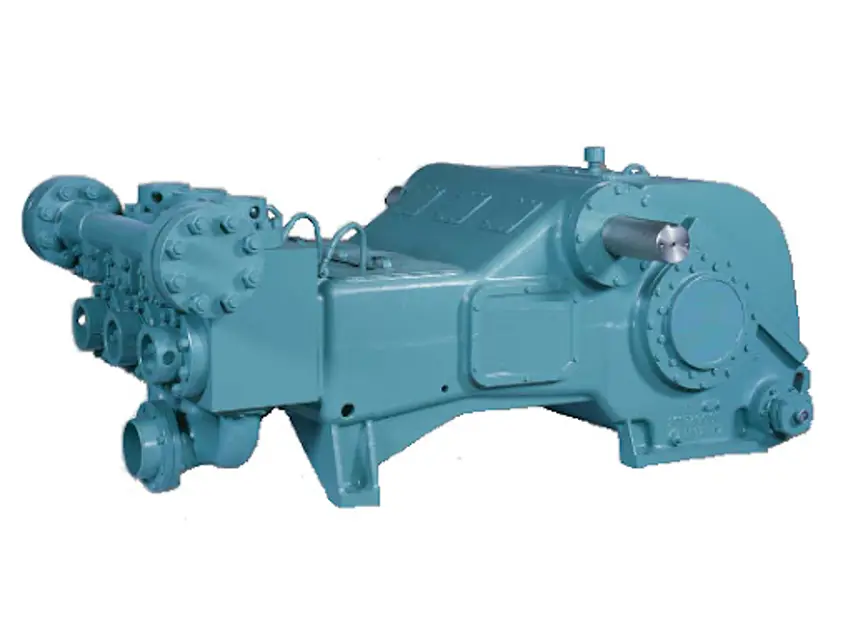

The Gardner Denver Single Acting Pump PZ-7 is a robust and efficient industrial pump designed for various applications. Known for its reliability and performance, this model is ideal for handling fluids in demanding environments, ensuring optimal operation and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Gardner Denver Single Acting Pump PZ-7

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Gardner Denver Single Acting Pump PZ-7

Create an account to install this asset package.

Maintenance Plans for Gardner Denver Single Acting Pump Model PZ-7

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Pump Maintenance

1. Remove valve covers and gaskets. Replace if cut or warn.

2. Check fluid valves and seats for wear. Replace cut or worn inserts and valves.

3. Inspect urethane bushing in suction and discharge valve guides and replace if worn.

4. Inspect piston locknut. Replace if damaged, corroded, or if nylon locking insert has lost its effectiveness. Nut should be used only three times and then replaced. Do not overtighten nuts.

Every Two Weeks:

1. Remove valve cover locks. Clean threads on locks and rings. Coat threads with moly coat thread compound or heavy–duty lead base thread compound. Replace if they are worn or cracked.;

1 Monthly Pump Maintenance

1. Check all fluid cylinder studs and nuts for tightness.

2. Remove and clean discharge cross strainer.

3. Check condition of oil stop head seals and replace if worn or leaking excessively.

Every 6 Months:

1. Replace oil stop head seals even though leakage is not evident.;

2 Daily Valves Inspection

Warning: This procedure requires trained personnel with PPE!

Examine the suction and discharge valves for wear or damage

Describe any worn or damaged parts found

Check the condition of the inserts

Warning: Use the Gardner–Denver puller powered with a hydraulic jack when removing a worn valve seat

Clean the tapered bore in the valve seat deck of the cylinder with a wire brush

Ensure the valve seat tapered surface is clean and dry before assembling in cylinder deck

Check the alignment of the discharge valve seats

Install the new seat in the bore

1000 Hourly Pump Maintenance

Clean frame oil drain magnet during oil change

Clean frame oil drain plug magnets located in front of crossheads and clean the oil passage

Clean inside frame during regular oil change

Sign off on the pump maintenance

1 Daily Pump Maintenance

Inspect condition of piston and liners. They should be run until leakage of fluid is visible or becomes excessive.

Clean inside frame cradle.

Clean and refill piston wash tank after excessive contamination.

Check piston wash baffle, make certain nozzles are not clogged.

Check pulsation dampener for proper charge.

Sign off on the daily pump maintenance

Parts for Gardner Denver Single Acting Pump PZ-7

Access the parts list for your equipment in MaintainX.

Plug, Cradle Drain

64AA9

Frame

201PZG001

Gasket, Hood

200PZG715

Plug-Magnetic, Sump Oil Drain

66D13

Gauge, Oil Temperature

27H11

Plug, Cradle Drain

64AA9

Frame

201PZG001

Gasket, Hood

200PZG715

Plug-Magnetic, Sump Oil Drain

66D13

Gauge, Oil Temperature

27H11

Plug, Cradle Drain

64AA9

Frame

201PZG001

Gasket, Hood

200PZG715

Plug-Magnetic, Sump Oil Drain

66D13

Gauge, Oil Temperature

27H11

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX