Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

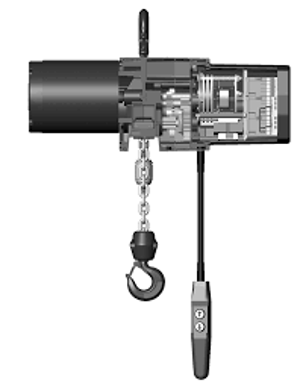

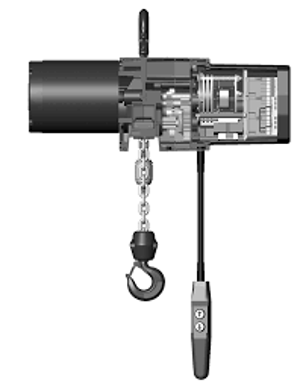

Manual for Dayton Electric Chain Hoist 3YE10

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Dayton Electric Chain Hoist 3YE10

Create an account to install this asset package.

Maintenance Plans for Dayton Electric Chain Hoist Model 3YE10

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Chain Hoist Maintenance

Inspect Operating Controls

Deficiencies in Operating Controls

Inspect Limit Switches

Deficiencies in Limit Switches

Inspect Brake Mechanism

Deficiencies in Brake Mechanism

Inspect Hooks

Deficiencies in Hooks

Inspect Suspension Lug (if used)

Chain Hoist Voltage Conversion

Warning: Always disconnect hoist from power supply before starting the procedure

Hoist disconnected from power supply

Remove the electrical cover

Electrical cover removed

Reconnect the leads to the terminal block according to the wiring diagram located inside the electrical cover

Leads reconnected according to the wiring diagram

Recheck phasing and limit switch operation after converting voltage

Phasing and limit switch operation checked

Check for securely fastened terminals and damaged insulation

Chain Replacement With Chain In Hoist

Run hook up to its limit

DISCONNECT HOIST FROM POWER SUPPLY and remove the electrical cover

Remove the spring guide plate from the slots in the limit switch nuts

Turn the slotted nut back to about the center of the threaded screw

Remove the load block assembly from old chain

Remove the chain stripper to detach the chain from the chain anchor and pull it through the load block assembly

Pull the chain out of the chain stripper

Make a 'C' link by grinding through the end link on the load end of the old chain

Attach the new chain to the load end of the old chain using the 'C' link

1 Monthly Load Hook Bearing Lubrication

Warning: Ensure the machine is turned off before starting the lubrication process

Select the type of service

Was the Load Hook Bearing lubricated with SAE 30 gear or motor oil?

Upload a photo of the lubricated Load Hook Bearing

Sign off on the Load Hook Bearing lubrication

1 Daily Chain Inspection

Chain is to be kept clean and lubricated.

Visually check chain every time hoist is used.

Hoist must not be operated when chain is twisted or kinked. An important phase of hoist maintenance is chain inspection. Check individual links and check for chain elongation.

1. Check the chain for overall wear or stretch by selecting an unworn, unstretched length of chain (at the slack end for example).; Let the chain hang vertically with a light load (about 20 pounds) on the chain to pull it taut.; Use a large caliper to measure the outside length of a convenient number of links about 12 inches).; Measure the same number of links in a used section of chain and calculate the percentage increase in length of the worn chain.

2. If the length of the worn chain is more than 1½% longer than the unused chain (0.015" per inch of chain measured), then the chain should be replaced.; If the chain is worn less than 1½%, check it at several more places along its length.

If any section is worn more than 1½%, the chain should be replaced.

CAUTION

The chain used on this hoist has very carefully controlled dimensions and has been heat treated. Do not attempt to substitute other manufacturer's chain.;

Parts for Dayton Electric Chain Hoist 3YE10

Access the parts list for your equipment in MaintainX.

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX