Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

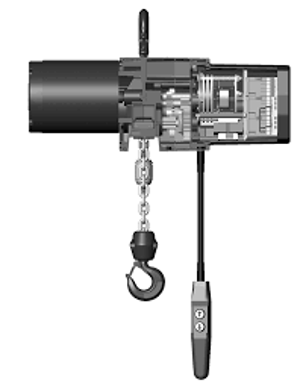

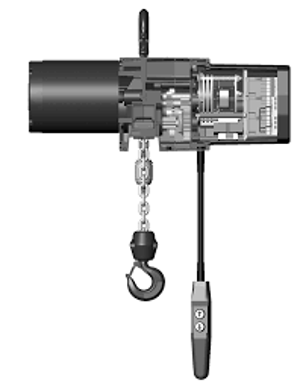

Manual for Dayton Electric Chain Hoist 3YB73

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Dayton Electric Chain Hoist 3YB73

Create an account to install this asset package.

Maintenance Plans for Dayton Electric Chain Hoist Model 3YB73

Integrate maintenance plans directly into your work orders in MaintainX.

Chain Hoist Lubrication

Proper lubrication is necessary for a long and relatively trouble-tree hoist operation.; Refer to the following and the RECOMMENDED LUBRICATION SCHEDULE for lubrication points, type of lubricant, and frequency of lubrication.

LOAD CHAIN.; Clean the load chain with acid-free solvent and coat with SAE 90 gear oil. Wipe excess oil to prevent dripping. Never apply grease to the chain.

GEARING.; The gear case of this hoist is filled at assembly with approximately 1½ pints of SAE 90 EP gear oil.; Check oil level by removing the oil level check plug from the side of the hoist. With the hoist hanging level, gear oil should be even with the hole.

BEARINGS. All bearings except hook and idler sheave bearings are lubricated at the factory and should not require additional lubrication. Noisy or worn bearings should be replaced.

LIMIT SWITCH SHAFT.; Remove any dirt accumulation and spray with a general purpose lubricant.

HOOK BEARING.; Apply a few drops of SAE 30 gear or motor oil around the edge of the bearing.

IDLER SHEAVE BEARING (BUSHING).; Disassemble load block and apply a light coat of NLGI #2 grease, or equivalent, inside of bearing.;

1 Monthly Chain Hoist Maintenance

Periodic — Indicates items requiring inspection monthly to yearly. Inspections to be performed by or under the direction of a properly designated period.; The exact period of inspection will depend on frequency and type of usage. Determination of this period will be based on the user’s experience.; It is recommended that the user begin with a monthly inspection and extend the periods to quarterly, semi-annually or annually based on user’s monthly experience.

1. Inspect Hook and Suspension

Possible Deficiencies:; - Cracks, bending, stripped threads Lug Connections

2. Inspect Pins, Bearings, Bushings; Possible Deficiencies:; - Excessive wear, corrosion, cracks, distortion Shafts, Couplings

3. Inspect Nuts, Bolts, Rivets

Possible Deficiencies:; - Looseness, stripped and damaged threads, corrosion

4. Inspect Sheaves

Possible Deficiencies:; - Distortion, cracks, and excessive wear.

- Build-up of foreign substances

Chain Hoist Voltage Conversion

Warning: Disconnect hoist from power supply before starting the procedure

Hoist disconnected from power supply

Remove the electrical cover

Electrical cover removed

Reconnect the leads to the terminal block according to the wiring diagram located inside the electrical cover

Leads reconnected according to the wiring diagram

Recheck phasing and limit switch operation after converting voltage

Phasing and limit switch operation checked

Check for damaged insulation and make sure all terminals are securely fastened

1 Weekly Load Hook Bearing Lubrication

Warning: Ensure the machine is turned off before starting the lubrication process

Select the type of service

Lubrication done with SAE 30 gear or motor oil

Upload a photo of the lubricated bearing

Sign off on the lubrication process

Chain Replacement With Chain In Hoist

Run hook up to its limit

DISCONNECT HOIST FROM POWER SUPPLY and remove the electrical cover

Remove the spring guide plate from the slots in the limit switch nuts

Turn the slotted nut back to about the center of the threaded screw

Remove the load block assembly from old chain

Remove the chain stripper to detach the chain from the chain anchor and pull it through the load block assembly

Pull the chain out of the chain stripper

Make a 'C' link by grinding through the end link on the load end of the old chain

Attach the new chain to the load end of the old chain using the 'C' link

Parts for Dayton Electric Chain Hoist 3YB73

Access the parts list for your equipment in MaintainX.

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX