Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

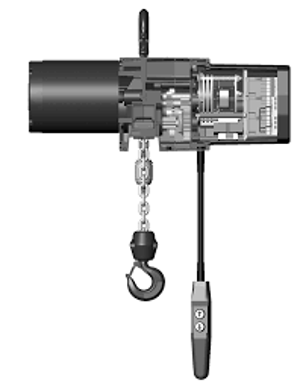

Manual for Dayton Electric Chain Hoist 3YB79

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Dayton Electric Chain Hoist 3YB79

Create an account to install this asset package.

Maintenance Plans for Dayton Electric Chain Hoist Model 3YB79

Integrate maintenance plans directly into your work orders in MaintainX.

Chain Hoist Voltage Conversion

Warning: Always disconnect hoist from power supply before starting the procedure

Hoist disconnected from power supply

Remove the electrical cover

Electrical cover removed

Reconnect the leads to the terminal block according to the wiring diagram located inside the electrical cover

Leads reconnected according to the wiring diagram

Recheck phasing and limit switch operation after converting voltage

Phasing and limit switch operation checked

Make sure all terminals are securely fastened and check for damaged insulation

Brake Adjustment

Warning: Disconnect hoist from power supply before starting the procedure

Hoist disconnected from power supply

Upload a photo of the electrical cover removed

Enter the gap between the brake armature and the field

Is the gap within the acceptable range (0.015\ - 0.040\")?"

Adjust the 3 locknuts and check with a feeler gauge to ensure the gap is the same on both ends of the solenoid

Is the bottom of the armature not bearing against the splined adapter?

Enter the disc thickness

Is the disc thickness above the minimum allowable (.162\)?"

1 Daily Hooks Inspection

Inspect hooks for cracking, extreme wear or spreading

Check if throat openings are spread wider than the maximum permissible 15% increase

Check if any hook is bent or twisted more than 10 degrees from the plane of an unbent hook

Inspect the hook latches to ensure that they close the hook throat opening in a secure manner when a load is applied

Inspect the hook shank and nut for any stripping of the threads or other damage

Check if the hook nut is fully restrained by the retaining pin

Inspect load hooks for cracks by the magnetic particle, dye penetrant or other suitable crack testing inspection method

Sign off on the daily hooks inspection

1 Yearly Limit Switch Shaft Lubrication

Warning: Only trained personnel should perform this procedure

Select type of service

Dayton Dem-Kote No. 5X628 multi-purpose oil available

Limit Switch Shaft lubricated

Sign off on the lubrication process

Chain Replacement With Chain In Hoist

Run hook up to its limit

DISCONNECT HOIST FROM POWER SUPPLY and remove the electrical cover

Remove the spring guide plate from the slots in the limit switch nuts

Turn the slotted nut back to about the center of the threaded screw

Remove the load block assembly from old chain

Remove the chain stripper to detach the chain from the chain anchor and pull it through the load block assembly

Pull the chain out of the chain stripper

Make a 'C' link by grinding through the end link on the load end of the old chain

Attach the new chain to the load end of the old chain using the 'C' link

Parts for Dayton Electric Chain Hoist 3YB79

Access the parts list for your equipment in MaintainX.

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Cover Screw

H2976P

Trim Cover

JM37

Transmission Housing

JM3533

Transmission Case Gasket

JM560

Transmission Cover

JM34

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX