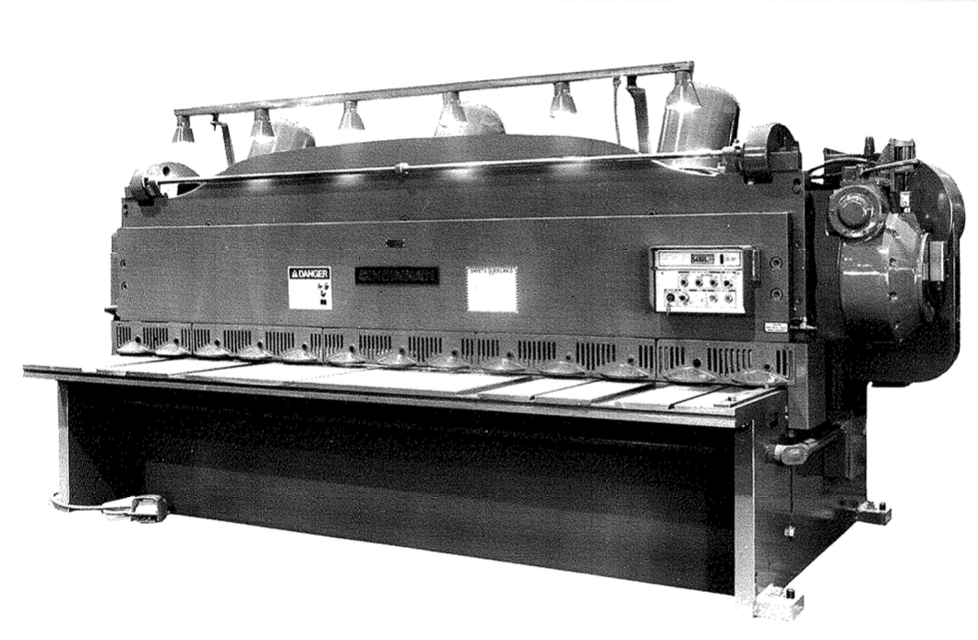

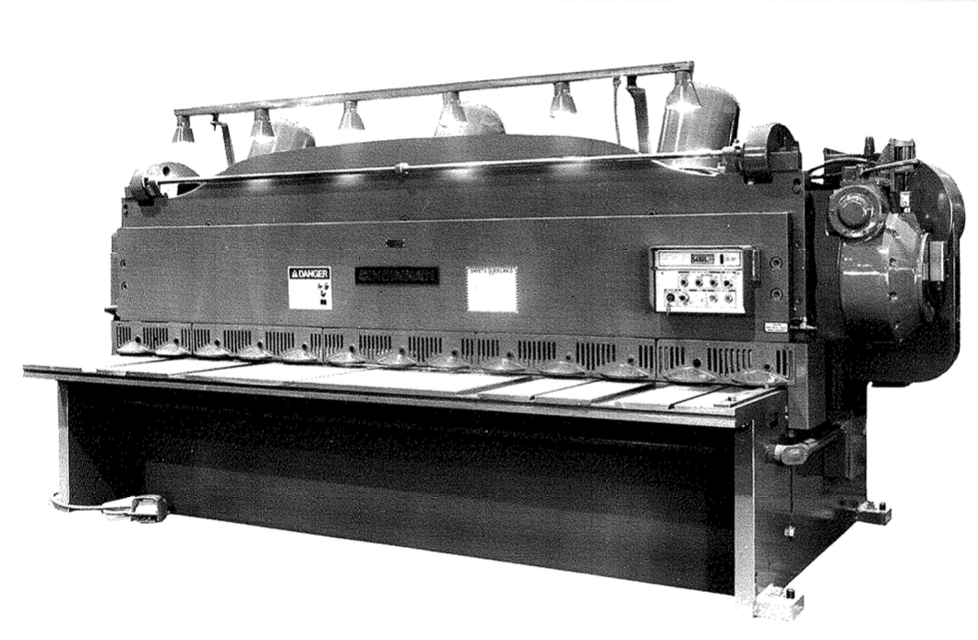

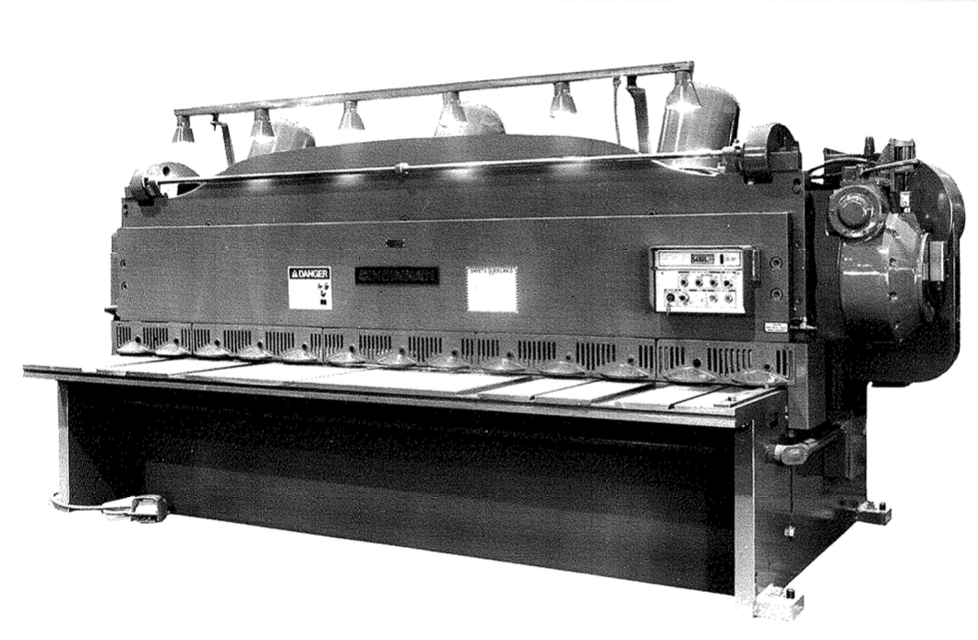

The Cincinnati Mechanical Shear 6220 is a robust industrial cutting tool designed for precision metal shearing. Known for its durability and efficiency, this model is essential for high-volume production environments, ensuring clean cuts and reliable performance in metal fabrication processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cincinnati Mechanical Shear 6220

Create an account to install this asset package.

Maintenance Plans for Cincinnati Mechanical Shear Model 6220

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Mechanical Shear Maintenance

Safety Maintenance Check

Safeguarding at point-of-operation in proper adjustment and repair.

Pinch point guarding properly installed.

Operator controls working properly.

Operating modes functioning properly.

Ram starting and stopping properly.

Instruction and warning signs clean and easily read.

Knives checked for sharpness and proper clearance.

Electrical wiring in good condition.

1 Monthly Mechanical Shear Maintenance

Safety Maintenance Check

Safeguarding at point-of-operation in proper adjustment and repair.

Pinch point guarding properly installed.

Operator controls working properly.

Operating modes functioning properly.

Ram starting and stopping properly.

Instruction and warning signs clean and easily read.

Knives checked for sharpness and proper clearance.

Electrical wiring in good condition.

3 Monthly Mechanical Shear Maintenance

Safety Maintenance Check

Safeguarding at point-of-operation in proper adjustment and repair

Pinch point guarding properly installed

Operator controls working properly

Operating modes functioning properly

Ram starting and stopping properly

Instruction and warning signs clean and easily read

Knives checked for sharpness and proper clearance

Electrical wiring in good condition

1 Yearly Mechanical Shear Maintenance

Safety Maintenance Check

Safeguarding at point-of-operation in proper adjustment and repair

Pinch point guarding properly installed

Operator controls working properly

Operating modes functioning properly

Ram starting and stopping properly

Instruction and warning signs clean and easily read

Knives checked for sharpness and proper clearance

Electrical wiring in good condition

1 Daily Mechanical Shear Maintenance

Safety Maintenance Check

Safeguarding at point-of-operation in proper adjustment and repair

Pinch point guarding properly installed

Operator controls working properly

Operating modes functioning properly

Ram starting and stopping properly

Instruction and warning signs clean and easily read

Knives checked for sharpness and proper clearance

Electrical wiring in good condition

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX