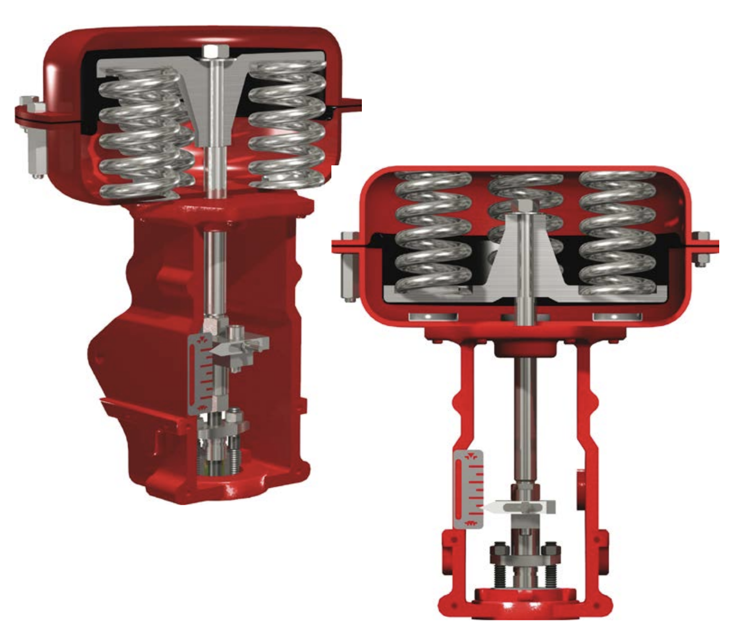

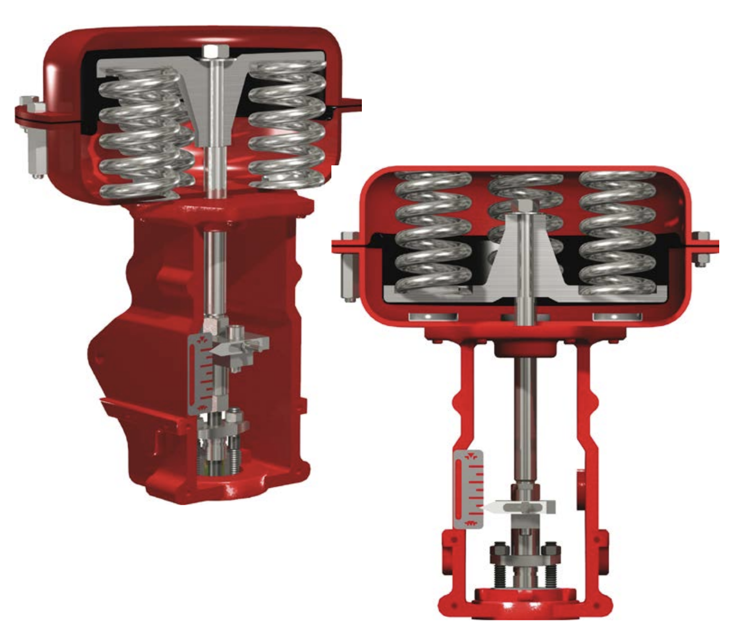

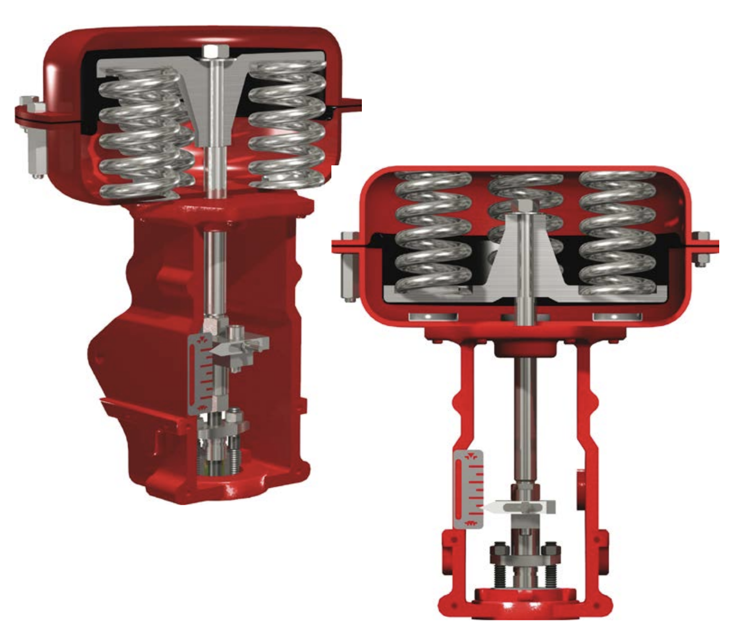

Baker Hughes Spring Diaphragm Actuators 87/88 Series are reliable and efficient devices designed for precise control in industrial applications. These actuators ensure optimal performance and longevity through effective maintenance strategies, making them essential for automation and process control systems.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Baker Hughes Spring Diaphragm Actuators 87/88 Series

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Baker Hughes Spring Diaphragm Actuators 87/88 Series

Create an account to install this asset package.

Maintenance Plans for Baker Hughes Spring Diaphragm Actuators Model 87/88 Series

Integrate maintenance plans directly into your work orders in MaintainX.

Spring Diaphragm Actuator Maintenance

Replace or repack handwheel bearing size 16 and 23 actuators A. Rotate handwheel to a free position.

B. Remove lock pin (91), cap screw (93), and washer (94) to release handwheel cover (57).

C. Remove pivot pins (33) which engage the handwheel pivot (36) thru the yoke.

D. Remove snap rings (46) and remove lever pin (45) to release complete handwheel assembly.

E. Remove cap screw (97) and end flange (96) to release the handwheel stem (39) from the bearing.

F. Remove snap ring (35) to release bearing (34).

G. Replace or clean to repack the bearing with new grease.

H. Pack bearing (34) with Mobilux No. 2 grease or equal.

I. For remounting, reverse removal procedures from step (F) through (B).;

1 Yearly Inspection

- The current estimated useful life period for the 87-88 Series Actuator is 25+ years. To maximize the useful life of the product, it is essential to conduct annual inspections, routine maintenance and ensure proper installation to avoid any unintended stresses on the product. The specific operating conditions will also impact the useful life of the product. Consult the factory for guidance on specific applications if required prior to installation.;

Spring Diaphragm Actuator Maintenance

Replace or repack handwheel bearing, size 3 actuators

A. Rotate handwheel to a free position.

B. Remove handwheel cap screw (20) and washer (42).

C. Remove handwheel (41) and key (47).

D. Remove one of the two retaining rings (46) which are mounted on lever pin (45).

E. Remove lever pin (45) and secure the handwheel holder (40) in place.

F. Remove the complete handwheel assembly from the actuator.

G. Remove both cover cap screw (20) and handwheel cover (57).

H. Remove retaining ring (35), handwheel pivot (36) and bushing (37) to release the bearing.

Spring Diaphragm Actuator Maintenance

Replace or repack handwheel bearing, size 6 and 10 actuators

A. Rotate handwheel to a free position.

B. Remove handwheel cap screw (20) and washer (42).

C. Remove handwheel (41) and lock nut (43).

D. Remove lock pin (91), cap screw (93), and washer (94) to release handwheel cover (57). Remove cover.

E. Remove pivot pins (33) from the yoke which hold the handwheel pivot (36).

F. Remove snap rings (46) and remove lever pin (45) to release handwheel assembly.

G. Turn handwheel stem (39) until it clears traveling nut (40).

H. Remove snap ring (38) and bearing ring (37) to release the handwheel stem (39) from the bearing.

Spring Diaphragm Actuator Maintenance

Replacing diaphragm air to close actuator (Model 87), with handwheel

A. Shut off air supply to the actuator, isolate the control process pressure to eliminate the valve plug from moving with spring tension removed.

B. Rotate the handwheel (41) to a neutral position.

C. For size 3 actuator, remove one of the two retaining rings (46) which are mounted on lever pin (45).

D. For size 3 actuator, remove lever pin (45) and secure the handwheel holder (40) in place (see Figures 11 and 12). For all other sizes, let the complete handwheel assembly swing down and out of the way of the top stem connector (4) [stem flange (2) on size 6 actuator].

E. Proceed with the instructions for air to close actuators without handwheel (7.3).;

Parts for Baker Hughes Spring Diaphragm Actuators 87/88 Series

Access the parts list for your equipment in MaintainX.

Stem Connector-Top

-

Cap Screw-Connecter

-

Hex Nut

-

Pointer

-

Retaining Ring

-

Stem Connector-Top

-

Cap Screw-Connecter

-

Hex Nut

-

Pointer

-

Retaining Ring

-

Stem Connector-Top

-

Cap Screw-Connecter

-

Hex Nut

-

Pointer

-

Retaining Ring

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX