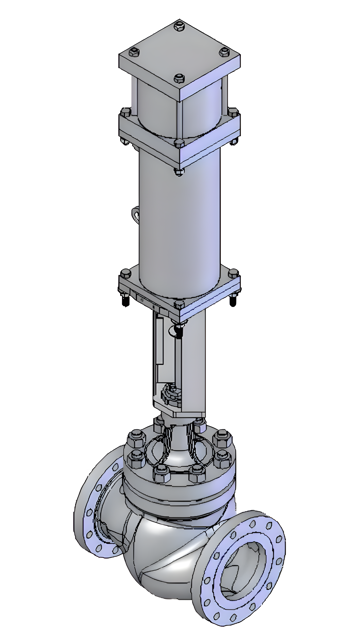

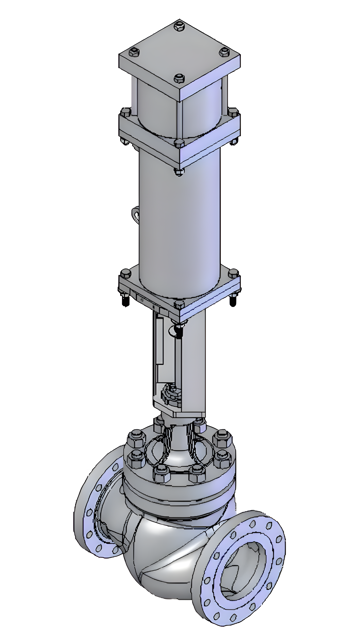

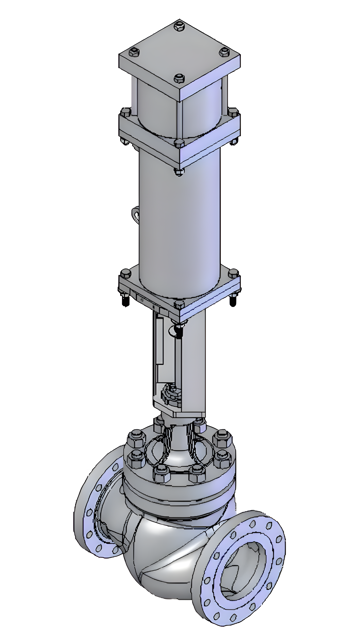

Baker Hughes Linear Piston Spring Return Actuators are designed for reliable and efficient operation in industrial applications. These actuators provide precise control and quick response, making them ideal for various automation needs. With robust construction and easy maintenance, they ensure optimal performance and longevity in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Baker Hughes Linear Piston Spring Return Actuators

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Baker Hughes Linear Piston Spring Return Actuators

Create an account to install this asset package.

Maintenance Plans for Baker Hughes Linear Piston Spring Return Actuatorsnull

Integrate maintenance plans directly into your work orders in MaintainX.

Replacing Tube Seals & Piston Seals

1. Remove the power gas to allow the actuator cylinder (A) to stroke to the spring position.

2. Depressurize all instrumentation.

3. Remove instrumentation tubing and instrumentation from the actuator cylinder (A).

4. Make a vertical reference mark between bottom mounting flange (B) and cylinder tube (C) to ensure proper realignment upon reassembly.

5. Remove tie rod nuts (D) from top flange (E). If tie rod nut (D) seizes and tie rod (F) unscrews, remove entire tie rod (F).

6. Remove tie rods (F), then remove top flange (E) and top seal O-ring (G).

7. Remove cylinder tube (C) and bottom seal O-ring (H) from bottom mounting flange (B).

8. Remove top piston U-cup (I) and bottom piston U-cup (J) from piston (K).

9. Remove any rust, dirt, or foreign material from cylinder tube (C) wall and piston (K) using solvent if needed.

Checking Tube Seals

1. Remove the pneumatic buffer system or desiccant canister. 2. Pressurize the normally pressurized side of the cylinder with at least 100 psig power supply gas. 3. Apply a leak-check solution around the perimeter of the cylinder tubing wall. Any leakage should be easily visible. 4. Follow procedure 5 on page 13 to replace tube seals.

Checking Piston Seals

1. Apply 100 psig power supply gas to the cylinder top port and ZERO pressure to the cylinder bottom port.

2. Remove the tubing fitting (and pneumatic buffer or desiccant canister) from the actuator cylinder bottom port.

3. Check for excessive piston seal leakage at the ZERO pressure port.

4. Apply 100 psig power gas supply to the cylinder bottom port and ZERO pressure to the cylinder top port.

5. Remove the tubing fitting from the actuator cylinder top port.

6. Check for excessive piston seal leakage at ZERO pressure port.;

Checking Buffer System or Vent Breather

1. For pneumatic buffer system, check for leaks around the check valve and up to the cylinder port to ensure the system is working.

2. For vent breather, replace the unit at the first signs of moisture inside the canister. For a working regulator, it is recommended to replace the cartridge annually. The replacement part number is 22-2542.

3. When additional accessories are used (MCV, Versa Valves, etc.) all parts must be connected through the check valve.;

Cylinder Piston Rod Leakage Inspection

1. Fully pressurize "rod" side of actuator cylinder.

2. Ensure both block valves are closed.

3. Observe gauge needle opposite from "rod" side of cylinder; if gauge needle moves, then piston seals (u-cups) may need replacement.

4. Repeat steps 1 and 2.

5. Observe gauge needle on "rod" side of cylinder. If needle shows a decrease in pressure, piston rod seals must be replaced. Follow procedure 6 on page 15 to replace piston rod seals.;

Parts for Baker Hughes Linear Piston Spring Return Actuators

Access the parts list for your equipment in MaintainX.

Piston

-

Tie Rod

-

Hex Nut

-

Tube Seal

-

Bearing

-

Piston

-

Tie Rod

-

Hex Nut

-

Tube Seal

-

Bearing

-

Piston

-

Tie Rod

-

Hex Nut

-

Tube Seal

-

Bearing

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX