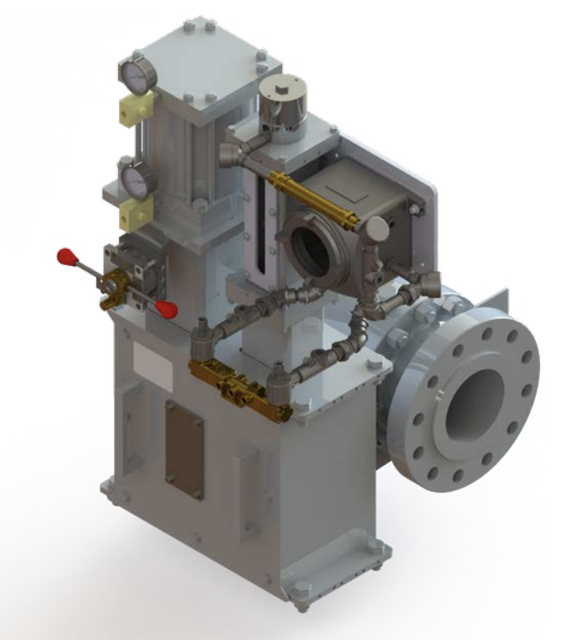

The Baker Hughes DNGP Series 3-5 is a cutting-edge Digital Natural Gas Positioner designed for precise control and efficiency in gas flow applications. This model ensures optimal performance and reliability, making it an essential component for modern industrial systems.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Baker Hughes DNGP Series 3-5 - Digital Natural Gas Positioner DNGP Series 3.5

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Baker Hughes DNGP Series 3-5 - Digital Natural Gas Positioner DNGP Series 3.5

Create an account to install this asset package.

Maintenance Plans for Baker Hughes DNGP Series 3-5 - Digital Natural Gas Positioner Model DNGP Series 3.5

Integrate maintenance plans directly into your work orders in MaintainX.

Digital Natural Gas Positioner Cleaning

All solenoid operators and valves should be cleaned periodically. The time between cleaning varies depending on medium and service conditions. In general, if the voltage to the solenoid is correct, sluggish valve operation, excessive noise or leakage indicates that cleaning is required. Clean strainer or filter when cleaning the valve.;

Digital Natural Gas Positioner Maintenance

- Faulty Control Circuit: Check the electrical system by energizing the solenoid. A metallic click signifies that the solenoid is operating. Absence of the click indicates loss of power supply. Check for loose or blown fuses, open circuited or grounded solenoid, broken lead wires or splice connections.

- Burned Out Solenoid: Check for open circuited solenoid. Replace if necessary. Check supply voltage: it must be the same as specified on nameplate/retainer and marked on the solenoid. Check ambient temperature and check that the core is not jammed.

- Low Voltage: Check voltage across the solenoid leads. Voltage must be at least 85% or rated voltage.;

Digital Natural Gas Positioner Testing

1. Switch DNGP to Standby from Auto. Observe feedback mA indicator. If position of the valve changes, continue to step 2.

2. Move MCV to Manual to close the block valve or close the cylinder block valves.

3. Check the cylinder for decaying or equalizing pressure. If cylinder pressure is: • Decaying - check and repair leaks at fittings. • Equalizing - rebuild the cylinder.

4. Check for external leak at gasket and NPT instrumentation ports: • If a leak is found - tighten bolts or fittings. • If no leak is found - check the solenoid valves.;

1 Monthly Maintenance

- Keep the medium flowing through the solenoid operator or valve as free from dirt and foreign material as possible.

- While in service, the solenoid operator or valve should be operated at least once a month to ensure proper opening and closing.

- Depending on the medium and service conditions, periodic inspection of internal valve parts for damage or excessive wear is recommended. Thoroughly clean all parts. Replace any worn or damaged parts.;

Digital Natural Gas Positioner Replacement

Replacing the Electronic Module of the Programmable

Linear Transmitter

1. Turn off the power and remove the four connecting wires.

2. Remove the two retaining screws with a 3 mm hex wrench.

3. Remove the Electronic Module from the housing and shaft.

4. The new transmitter module can be either 20 mA Down or 20 mA Up depending on the position of Dip Switch #2 (See Figure 34).

To program the transmitter to the: • 20 mA Down mode (the 20 mA signal is generated at the end of the shaft): Dip Switch #2 is down or off. • 20 mA Up mode (the 20 mA signal is generated close to the body): Dip Switch #2 is up or on.

5. Insert the new electronic module back on the transmitter housing, connect the four wires and turn the power to On.

6. Insert the two screws with hex wrench, connect the wires and power the unit.;

Parts for Baker Hughes DNGP Series 3-5 - Digital Natural Gas Positioner DNGP Series 3.5

Access the parts list for your equipment in MaintainX.

DNGP Terminal Block

31-0017

Balluff BTL5

01-8975

DNGP Positioner

31-0511

Balluff BTL5

01-8977

ASCO Solenoid Valve

20-4203

DNGP Terminal Block

31-0017

Balluff BTL5

01-8975

DNGP Positioner

31-0511

Balluff BTL5

01-8977

ASCO Solenoid Valve

20-4203

DNGP Terminal Block

31-0017

Balluff BTL5

01-8975

DNGP Positioner

31-0511

Balluff BTL5

01-8977

ASCO Solenoid Valve

20-4203

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX