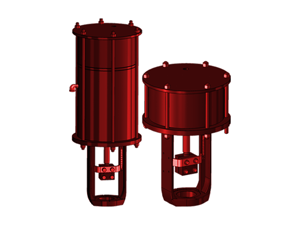

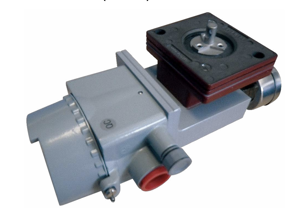

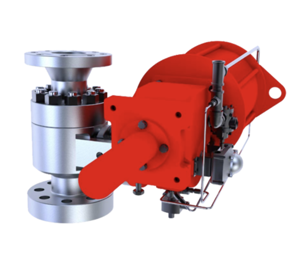

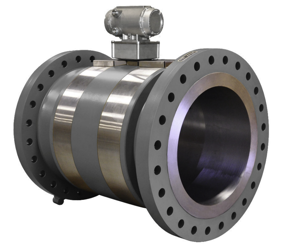

The Baker Hughes Steam Conditioning Control Valve 84003 Series SteamFormTM is designed for precise steam flow control in industrial applications. This high-performance valve ensures optimal efficiency and reliability, making it essential for effective steam management in various processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Baker Hughes Steam Conditioning Control Valve 84003 Series SteamFormTM

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Baker Hughes Steam Conditioning Control Valve 84003 Series SteamFormTM

Create an account to install this asset package.

Maintenance Plans for Baker Hughes Steam Conditioning Control Valve Model 84003 Series SteamFormTM

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Maintenance

- The current estimated useful life period for the 84003 Series SteamForm is 25+ years. To maximize the useful life of the product, it is essential to conduct annual inspections, routine maintenance and ensure proper installation to avoid any unintended stresses on the product. The specific operating conditions will also impact the useful life of the product. Consult the factory for guidance on specific applications if required prior to installation.;

Steam Conditioning Control Valve Maintenance

- Packing Box

Tight sealing within the packing box is obtained by compression of the packing. Compression must be achieved by evenly tightening the packing flange nuts on the packing flange. Periodic re-tightening of the packing flange nuts may be required to maintain proper sealing.

- PTFE Packing

KevlarTM/PTFE, carbon/PTFE and pure PTFE packing rings are cut in such a way that they can be replaced without having to separate the valve plug stem from the actuator stem.

1. Unscrew and remove the packing flange nuts.

2. Lift the packing flange and packing follower up along the valve stem.

3. By means of a puller, remove the packing being careful not to damage the seating surface of the packing box or the valve plug stem.

4. Replace the packing rings, placing the cut in each ring about 120° apart from the adjacent ring. Press rings in one at a time.

5. Reassemble the packing follower and the packing flange.

Parts for Baker Hughes Steam Conditioning Control Valve 84003 Series SteamFormTM

Access the parts list for your equipment in MaintainX.

Auxiliary Pilot Plug

-

Body Stud

-

Body

-

Pilot Spring

-

Flow profiler/Lo-dB plate

-

Auxiliary Pilot Plug

-

Body Stud

-

Body

-

Pilot Spring

-

Flow profiler/Lo-dB plate

-

Auxiliary Pilot Plug

-

Body Stud

-

Body

-

Pilot Spring

-

Flow profiler/Lo-dB plate

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX