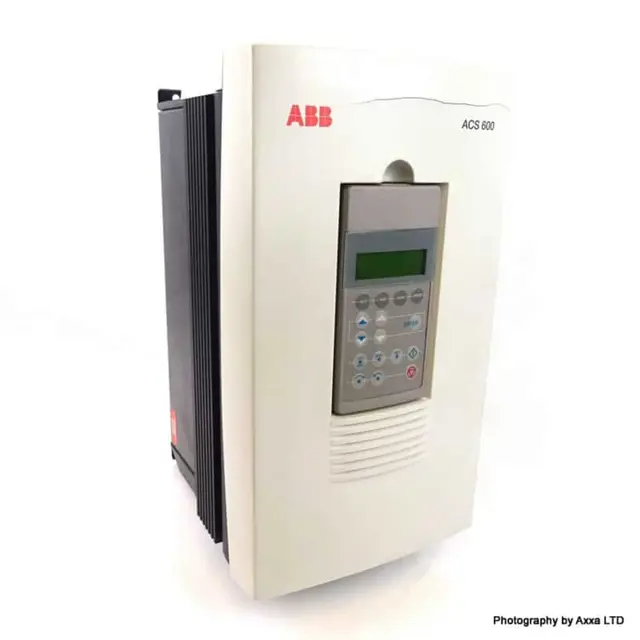

The ABB MultiDrive ACS600 is a versatile industrial drive system designed for efficient motor control and energy savings. This model offers advanced features for precise speed and torque management, making it ideal for various applications in manufacturing and automation.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for ABB MultiDrive ACS600

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

ABB MultiDrive ACS600

Create an account to install this asset package.

Maintenance Plans for ABB MultiDrive Model ACS600

Integrate maintenance plans directly into your work orders in MaintainX.

40000 Hours Replacement

- The cooling fan lifespan is approximately 40,000 hours. The actual lifespan depends on the frequency converter usage and ambient temperature. Fan failure can be predicted by increasing noise from fan bearings and gradual rise in the heatsink temperature in spite of heatsink cleaning. If the frequency converter is used in a critical part of a process, fan replacement is recommended once these symptoms appear.;

1 Yearly Maintenance

- When having filtering for cooling air, check and clean or replace filter mats if dirty. Wash dirty filter mats with water (60 °C) and detergent.

- The ACx 600 can run into overtemperature faults if the heatsink is not clean. In normal environment, the heatsink should be checked and cleaned annually. Use compressed air to remove dust from the heatsink. (The airflow direction must be from bottom to top.) Also, use a vacuum cleaner at the air outlet to trap the dust. Fan rotation must be prevented in order to prevent bearing damage.

- If spare modules are available, it is recommended to replace the cabinet modules with their spare modules once a year in order to avoid capacitor reforming and to equalize wear and tear on the modules. See section Capacitors below.

- Converter DC link capacitors need to be reformed (re-aged) if the converter has been non-operational for more than one year. Without reforming capacitors may be damaged when the converter starts to operate. The reforming methods introduced here require that the converter has been stocked clean and dry. It is recommended to reform the capacitors once a year.

100000 Hours Replacement

- The ACx 600 intermediate circuit employs several electrolytic capacitors. The lifespan of the capacitors is approximately 100,000 hours, depending on the frequency converter loading and the ambient temperature

- Capacitor life can be prolonged by lowering the ambient temperature. It is not possible to predict capacitor failure. Capacitor failure is usually followed by a mains fuse failure or a fault trip. Contact ABB if capacitor failure is suspected. Replacements are available from ABB. Do not attempt operation with other than ABB specified spare parts.;

Maintenance

- Relays should be checked for function and all connections should be inspected and checked for tightness. Any signs of corrosion, especially in ground components, shall be cleaned off.

- The intermediate circuit of the converter is kept at its nominal voltage for the reforming time to "wake up" the capacitors. The reforming time required depends on how long the converter has been stocked (non-operational).;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX