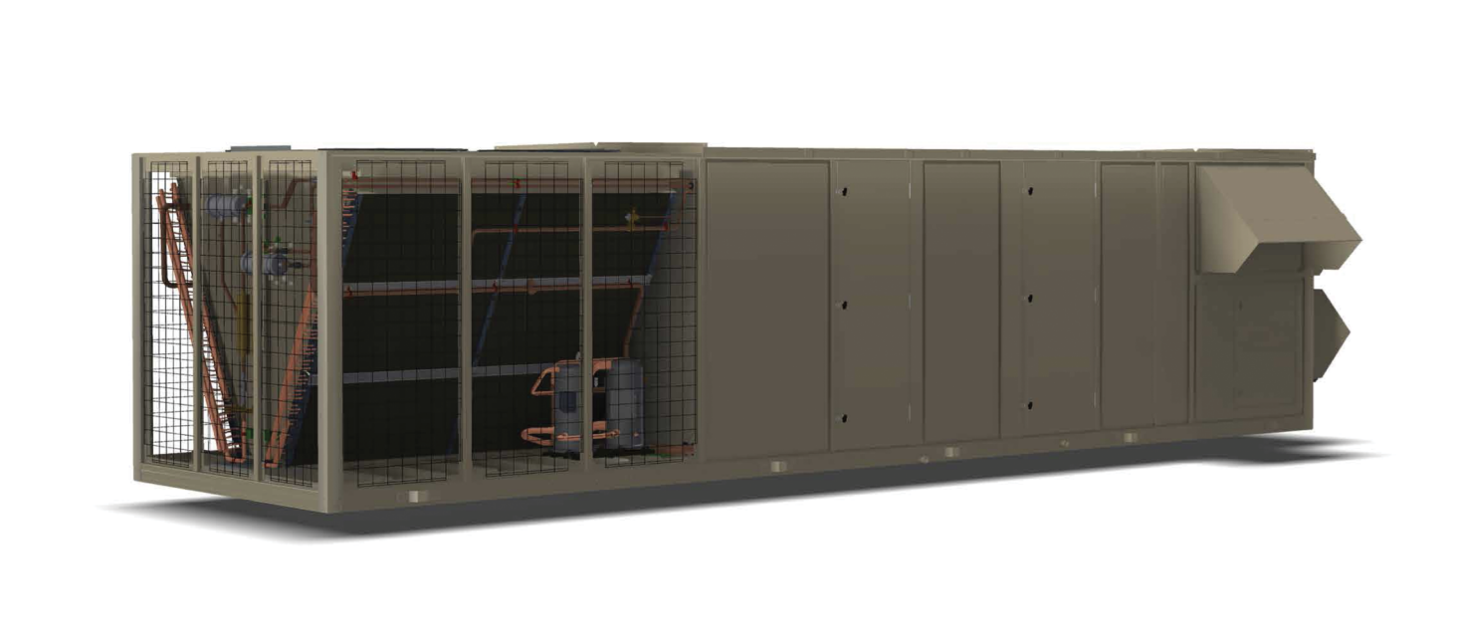

The York Packaged Rooftop Air Conditioning Units YPAL 061 are designed for efficient climate control in commercial settings. These robust units offer reliable performance and ease of maintenance, ensuring optimal indoor air quality and comfort. Ideal for various applications, they combine advanced technology with user-friendly features for effective cooling solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for York PACKAGED ROOFTOP AIR CONDITIONING UNITS YPAL 061

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

York PACKAGED ROOFTOP AIR CONDITIONING UNITS YPAL 061

Create an account to install this asset package.

Maintenance Plans for York PACKAGED ROOFTOP AIR CONDITIONING UNITS Model YPAL 061

Integrate maintenance plans directly into your work orders in MaintainX.

MONTHLY MAINTENANCE

Check the cleanliness of the filters and replace or clean as required.

Linkages:

Examine the damper and operator linkages to ensure that each is free and operating smoothly.

Compressors:

Oil Level Check: The oil level can only be tested when the compressor is running in stabilized conditions, to ensure that there is no liquid refrigerant in the lower shell of the compressor. When the compressor is running in stabilized conditions, the oil level must be be tween 1/4 and 3/4 in the oil sight glass. Note: at shut down, the oil level can fall to the bot tom limit of the oil sight glass.

Oil Analysis: Use York Type “T” POE oil (clear) for units charged with R-410A refrigerant. The type of refrigerant and amount per system is listed on the unit rating plate. A change in the oil color or odor may be an indication of contaminates in the refrigeration system. If this occurs, an oil sample should be taken and analyzed. If contaminations are present, the system must be cleaned to prevent compressor failure.

This can be accomplished through the installation of oversized suction and liquid line driers. The driers may have to be changed several times to clean up the system depending on the degree of contamination.

Fan Bearing Lubrication

Add grease slowly with shaft rotating until a slight bead forms at the seals. If necessary, re-lubricate while bearing is stationary. The fan data plate (attached to the fan scroll) lists the type of grease that must be used for lubricating the bearings. Refer to Table 4-1 for lubricating schedule.

YEARLY MAINTENANCE

Entire Unit Inspection:

In addition to the checks listed in this section, periodic over all inspections of the unit should be ac com plished to ensure proper equipment operation. Items such as loose hardware, component operation, refrigerant leaks, unusual noises, etc. should be investigated and corrected immediately.

Sheave Alignment:

To check sheave alignment, a straight edge or a piece of string can be used. If the sheaves are properly aligned, the string or straight edge will touch at all points, as indicated in Figure. 4-1. Rotating the sheaves will determine if the sheave is wobbly or the drive shaft is bent. Alignment error must be corrected to avoid bearing and belt failure.

New belts should be re-checked after 24 hours of operation. On multiple belt adjustable pul leys, the pitch depth should be checked to insure identical belt travel, power transfer and wear. Adjustable motor bases are provided for belt adjustment.

Motor pulleys and blower shaft pulleys are locked in position with either set screws or split taper lock bushings. All set screws and/or taper lock bolts must be checked for tightness and alignment be fore putting equipment into operation.

Filter Drier Replacement

The filter/drier should be replaced any time work is performed on the refrigerant circuit. The rooftop unit comes with sealed type (non-replaceable) cores as standard. If the unit is not equipped with the optional valve package (suction, discharge, & liquid line valves), the refrigerant will need to be recovered with a recovery machine to replace the filter/drier.;

QUARTERLY MAINTENANCE

Motor Bearing Lubrication

Bearings must be re-lubricated periodically to assure long life. Motor bearing should be lubricated yearly, but may need lubrication more frequently, depending on severe operating conditions.

Belt Tension

Adjust the belt tension if necessary. Re quired belt tension data is supplied on the fan “skid” data plate, attached to the fan housing. Never use a belt dressing on the belts. If belts slip with the prop er tension, use a good grade of belt cleans er to clean the belts.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX