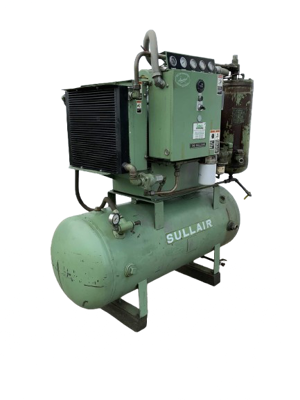

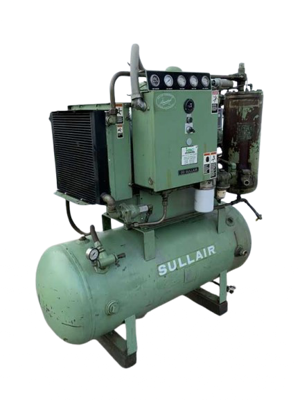

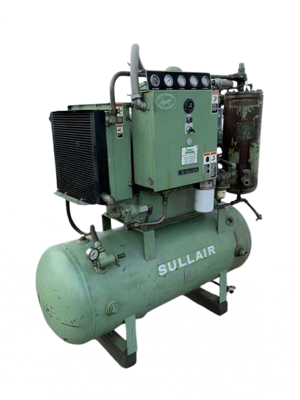

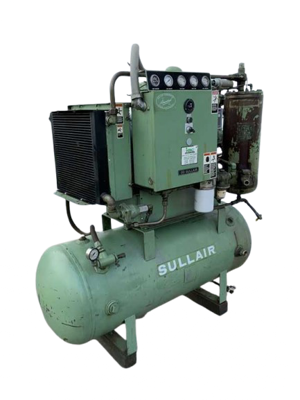

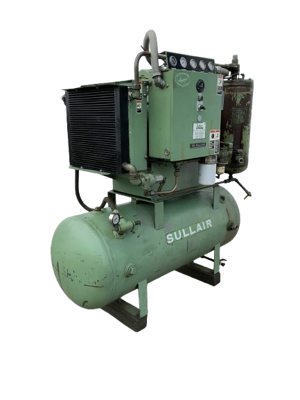

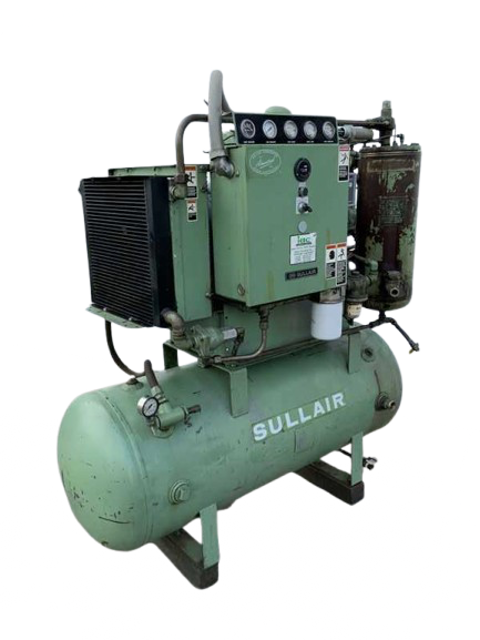

The Sullair Air-Cooled Compressor 10B 30 AC is a reliable and efficient industrial compressor designed for various applications. Known for its durability and performance, this model ensures optimal air delivery while minimizing downtime through effective maintenance strategies. Experience enhanced productivity with Sullair's trusted engineering.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Sullair Air-Cooled Compressor 10B 30 AC 10B 30 AC

Create an account to install this asset package.

Maintenance Plans for Sullair Sullair Air-Cooled Compressor 10B 30 AC Model 10B 30 AC

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Compressor Maintenance

Check the fluid level in the sump. Should the level be low, simply add the necessary amount

Observe the gauges and indicators to be sure they monitor the correct readings for that particular phase of operation

Check on the overall compressor and gauges to assure that the compressor is running properly after it has warmed up

Clean the return line strainer after the initial 50 hours of operation

Clean the return line orifice after the initial 50 hours of operation

Sign off on the daily compressor maintenance

Compressor Thermal Valve Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Remove the appropriate piping from the thermal valve housing

Remove the four (4) capscrews holding the housing together and separate the upper housing from the lower housing

Remove element

Remove and replace the element seal in the upper housing

Remove and replace the o-ring between the upper and lower housings

Replace element

Re-assemble the housing

Sign off on the thermal valve maintenance

Compressor Solenoid Valve Maintenance

WARNING: Turn off all power, relieve line pressure, and disconnect coil lead wires to the valve before making repairs

It is not necessary to remove the valve from the pipe line for repairs

Clean solenoid valve (P/N 250017-993)

Remove the retaining cap and slip the entire solenoid off the solenoid base subassembly

Unscrew the solenoid base assembly. Remove the core assembly, core spring and body gasket

Remove the end cap, body gasket, disc spring, and disc holder assembly

Replace worn or damaged parts with repair kit number 250018-970

Reassemble in reverse order of disassembly

Sign off on the compressor solenoid valve maintenance

6 Monthly Air Filter Element Inspection

Place a bright light inside the element to inspect for damage or leak holes. Concentrated light will shine through the element and disclose any holes

Inspect all gaskets and gasket contact surfaces of the housing. Should faulty gaskets be evident, correct the condition immediately

If the clean element is to be stored for later use, it must be stored in a clean container

After the element has been installed, inspect and tighten all air inlet connections prior to resuming operation

Sign off on the air filter element inspection

Compressor Coil Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Enter the part number of the coil

Retaining clip removed

Yoke containing the coil and sleeves slipped off the solenoid base sub-assembly

Reassembled in reverse order of disassembly

Sign off on the compressor coil maintenance

Parts for Sullair Sullair Air-Cooled Compressor 10B 30 AC 10B 30 AC

Access the parts list for your equipment in MaintainX.

Repair Kit

250034–112

Element

250025–525

Repair Kit

250018–970

Repair Kit

001836–007

Water Separator/Trap

040847

Repair Kit

250034–112

Element

250025–525

Repair Kit

250018–970

Repair Kit

001836–007

Water Separator/Trap

040847

Repair Kit

250034–112

Element

250025–525

Repair Kit

250018–970

Repair Kit

001836–007

Water Separator/Trap

040847

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX