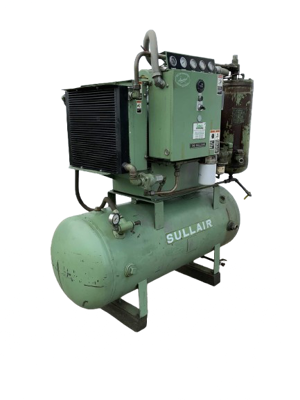

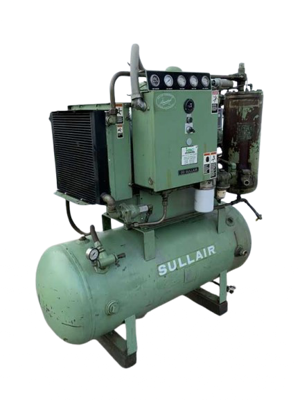

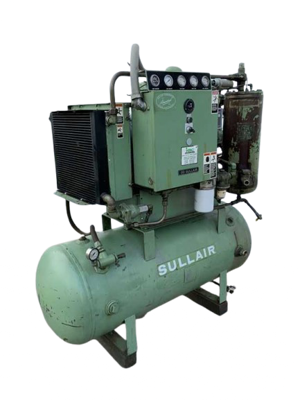

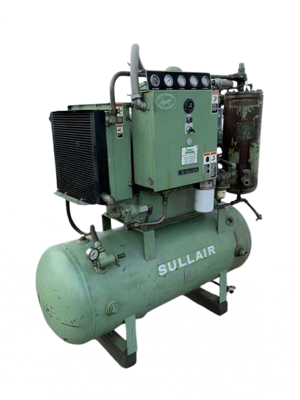

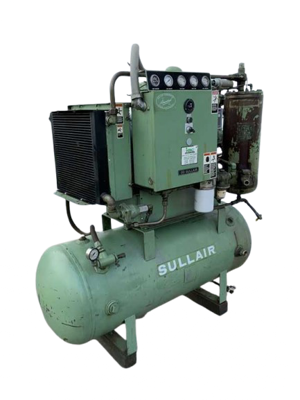

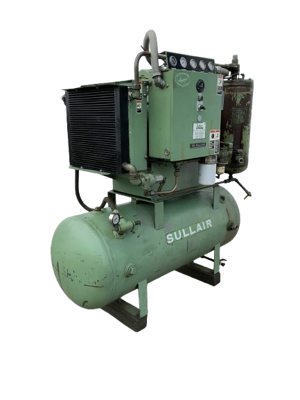

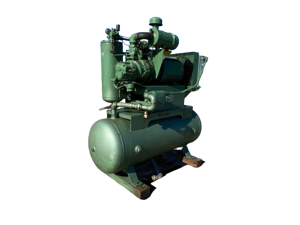

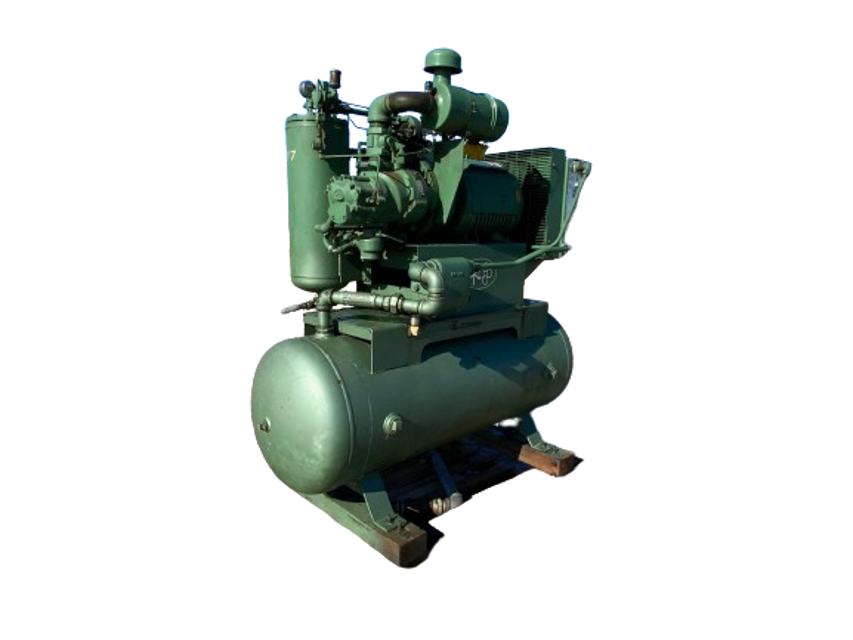

The Sullair Air-Cooled Compressor 10B 25HP-251332-004 AC is a reliable industrial compressor designed for efficient air delivery. Known for its durability and performance, this model is ideal for various applications requiring compressed air solutions. Ensure optimal operation with regular maintenance and quality spare parts.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Sullair Air-Cooled Compressor 10B 25HP-251332-004 AC 10B 25HP-251332-004 AC

Create an account to install this asset package.

Maintenance Plans for Sullair Sullair Air-Cooled Compressor 10B 25HP-251332-004 AC Model 10B 25HP-251332-004 AC

Integrate maintenance plans directly into your work orders in MaintainX.

Compressor Control System Maintenance

Warning: This procedure requires trained personnel with PPE!

Adjust Control System with a desired operating range of 115 to 125 PSIG (792 to 862kPa).

Enter the current operating range

FOR PRESSURE RANGE ADJUSTMENT:

Remove cover to pressure switch

Turn the range adjusting screw to the high pressure setting. Turning the screw counterclock-wise lowers both the high and low pressure equally

FOR DIFFERENTIAL ADJUSTMENT:

Turn the differential adjusting screw to the lower (reset) setting. Turning the screw counterclock- wise widens the differential by lowering the reset (lower) setting only

When the pressure switch adjustment is complete, the pressure regulator should be adjusted for the pressure at which modulation of air delivery should begin.

Compressor Minimum Pressure/ Check Valve Maintenance

WARNING: Before performing maintenance on the valve, be sure that all pressure has been relieved in the compressor sump, and all downstream pressure has been vented to the atmosphere. Also be sure that the components of the compressor are cool to the touch

Unscrew the minimum pressure/check valve (P/N 241581) from the receiver cover

Remove the hexagonal retaining cap from the main body

Remove the flat washer and heavy spring from the main body

Tap the piston assembly (with a screwdriver) from the bottom of the main body and remove. The o-ring will now be seen easily

Remove the seal ring and discard

Clean piston assembly and valve thoroughly

Replace seal ring and coat the piston and seal with Parker Super “O” Ring Seal or an equivalent quality grease

WARNING: Extreme caution should be used when removing the cap from the body because there is spring tension on the cap

Compressor Maintenance

PIPE END PREPARATION

Deburr and clean the pipe ends

The pipe ends are free of all deep scratches, gouges, dents, etc.

JOINT INSTALLATION

Install the retainer (1), gasket (2), and sleeve (3) on one side of the pipe as shown in Step 1

Install the remaining retainer (4) and gasket (5) on the other pipe end

Position the retainer (4) and gasket to proper pipe insertion depth (“D”)

Slide the sleeve (3) to the gasket (5) and move gasket (2) and retainer (1) into position as shown in Step 2. The pipe MUST be inserted to the proper depth (“D”) into both gaskets

COUPLER INSTALLATION

6 Monthly Air Filter Element Replacement

Clean exterior of air filter housing

Remove the air filter cover by loosening the wingnut securing the cover

Remove element and clean interior of housing using a damp cloth. DO NOT blow dirt out with compressed air

Clean or replace the element

Replace cover

Reset the filter maintenance indicator

Sign off on the air filter element replacement

Compressor Thermal Valve Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Remove the appropriate piping from the thermal valve housing

Remove the four (4) capscrews holding the housing together and separate the upper housing from the lower housing

Remove element

Remove and replace the element seal in the upper housing

Remove and replace the o-ring between the upper and lower housings

Replace element

Re-assemble the housing

Sign off on the thermal valve maintenance

Parts for Sullair Sullair Air-Cooled Compressor 10B 25HP-251332-004 AC 10B 25HP-251332-004 AC

Access the parts list for your equipment in MaintainX.

Solenoid Valve

250017–993

Flexible Coupling

250007–544

Air Inlet Valve

250025–654

Repair Kit

250025–621

Blowdown Valve

250025–655

Solenoid Valve

250017–993

Flexible Coupling

250007–544

Air Inlet Valve

250025–654

Repair Kit

250025–621

Blowdown Valve

250025–655

Solenoid Valve

250017–993

Flexible Coupling

250007–544

Air Inlet Valve

250025–654

Repair Kit

250025–621

Blowdown Valve

250025–655

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX