Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

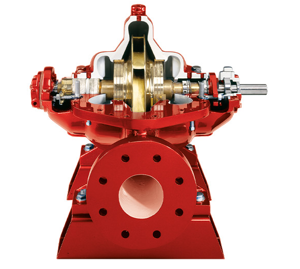

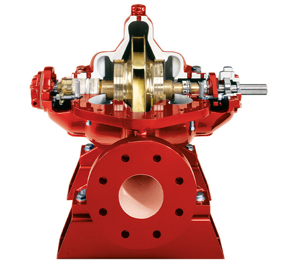

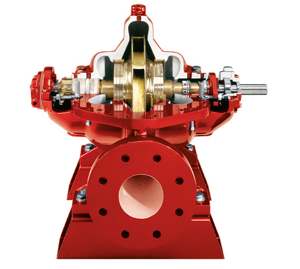

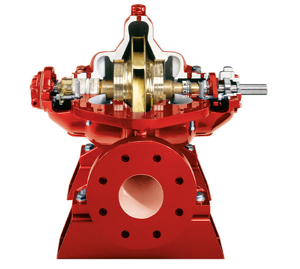

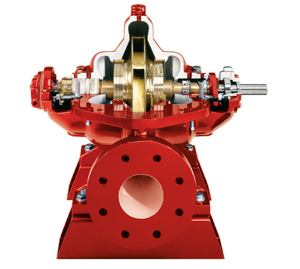

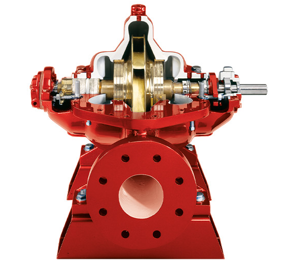

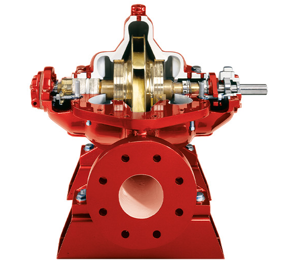

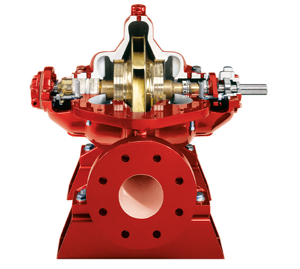

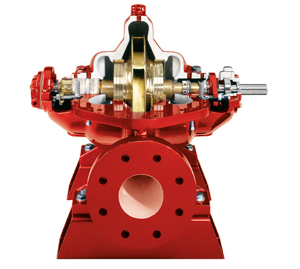

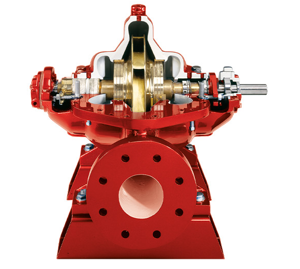

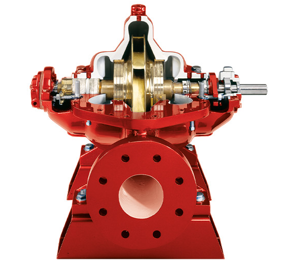

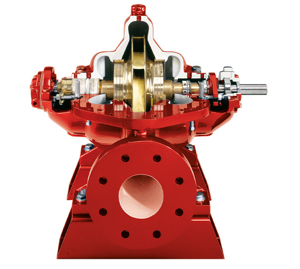

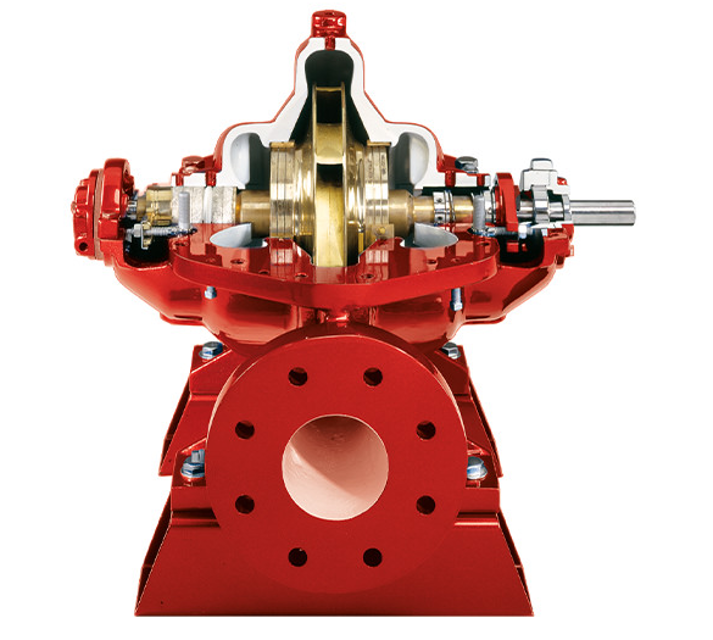

Manual for Peerless Pump Company Vertical Turbine Industrial Pumps Open Line Shaft 8MFH

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Peerless Pump Company Vertical Turbine Industrial Pumps Open Line Shaft 8MFH

Create an account to install this asset package.

Maintenance Plans for Peerless Pump Company Vertical Turbine Industrial Pumps Open Line Shaft Model 8MFH

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Vertical Turbine Industrial Pumps Open Line Shaft Check

Warning: This check requires trained personnel with PPE!

Pump-motor alignment: Check for change in alignment

Vibration: Check for change in vibration

Fasteners: Check for loose fasteners

Report any problems found during the inspection

Sign off on the pump inspection

2000 Hourly / 3 Monthly Packing Box Inspection

Warning: This inspection requires trained personnel with PPE!

Packing, packing box inspection

Inspect for excessive leakage

Report any problems found during the inspection

Sign off on the packing box inspection

Initial 150 Hours Packing Box Inspection

Warning: This inspection requires trained personnel with PPE!

To ensure satisfactory operation of the pumping equipment, frequent inspection and periodic maintenance are required.

An inspection and maintenance log should be kept and the inspector is to immediately report any problems.

Unusual applications with abnormal heat, moisture, dust, etc., may require more frequent inspection and service.

Packing box inspected for excessive leakage?

Describe the condition of the packing box

Sign off on the packing box inspection

Vertical Turbine Industrial Pumps Open Line Shaft Maintenance

Warning: Drain the pump and isolate pipework before dismantling the pump.

Warning: There may be occasions when a part such as the impeller has either been shrunk-fit onto the pump shaft or has become difficult to remove due to products that are corrosive in nature.

Warning: Before opening the terminal box of an electric motor, make sure that the power supply has been switched off.

Is the area adjacent to the pump cleared for storage of pump parts?

Are parallel timbers arranged on the ground to support the pump column and shaft sections horizontally?

Is the discharge pipe disconnected from the discharge head?

If the driver is equipped with an oil-cooling system, is the external tubing or piping removed?

On pumps equipped with an air-pressure water level testing system, is the gauge removed and the tubing connection inside the discharge head disconnected?

Is the electrical connection of the motor at the terminal box removed?

2000 Hourly / 1 Yearly Bearings Lubrication

Warning: This maintenance check requires trained personnel with PPE!

To ensure satisfactory operation of the pumping equipment, frequent inspection and periodic maintenance are required. An inspection and maintenance log should be kept and the inspector is to immediately report any problems.

Unusual applications with abnormal heat, moisture, dust, etc., may require more frequent inspection and service.

Bearings: Lubricate (grease);

Lubricating Process:

Sign off on the bearings lubrication

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX