The Mikasa Forward Plate Compactor MVC-T90H is a robust and efficient compaction solution designed for construction and landscaping applications. Known for its durability and performance, this model ensures optimal soil compaction, making it an essential tool for professionals in the industry.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Mikasa Forward Plate Compactor MVC-T90H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Mikasa Forward Plate Compactor MVC-T90H

Create an account to install this asset package.

Maintenance Plans for Mikasa Forward Plate Compactor Model MVC-T90H

Integrate maintenance plans directly into your work orders in MaintainX.

200 Hourly Clutch Check

CAUTION! Always stop the engine before inspection and adjustment. If you are caught in a rotating part, serious injury might occur.

Inspect Clutch concurrently with the inspection of V-belt.

Check visually for burning of each clutch-shoe.

Check for wear the lining shoe or the like, in the operation check.

If the shoe wears, power transmission is not performed properly and Clutch slips.

Check wear or any damage to V-groove also.

If V-groove is stained, clean it thoroughly.

Sign off on the 200 Hourly Clutch Check

200 Hourly / 1 Monthly Vibrator Oil Maintenance

Make sure the machine is level and remove the oil level plug off the vibrator.

Check if vibrator oil is provided up to the mouth level.

The oil level plug is on the right side of the vibrator case (opposite to the belt side).

Use the engine oil #10W-30 for vibrator oil.

Refer to page 8 for the amount.

Drain the vibrator oil completely by removing the plug and tilting the body once a month or every 200 hours’ operation.

Replace with new oil.

Sign off on the vibrator oil maintenance

100 Hourly Forward Plate Compactor Maintenance

• Replace Engine Oil

• Wash Engine Oil Filter

• Check Vibrator Oil leakage, oil level, dirt;

Air Cleaner Replacement

Warning: Dirty air cleaner element can affect machine operation and shorten engine life.

Does the engine start smoothly?

Is the air cleaner element clean?

Did you clean the element?

If the element cannot be cleaned, replace it.

Upload a photo of the new air cleaner element

Sign off on the air cleaner replacement

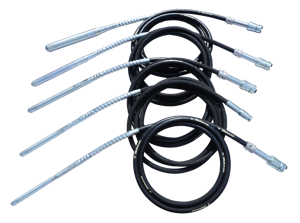

200 Hourly V-Belt Check

CAUTION! When the vibration weakens during operation, or this machine does not vibrate at all though the engine rotates normally, conduct the inspection or change of the V-belt and clutch without regard to the regular inspection of every 200 hours. Always stop the engine before inspection and adjustment. If you are caught in a rotating part, serious injury might occur.

Remove the belt cover and check that V-belt is properly stretched every 200 hours.

Press on the portion midway between the two shafts with your fingers strongly.

The belt is properly stretched if that portion bows by about 10-15 mm.

Sign off on the V-belt check

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX