Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

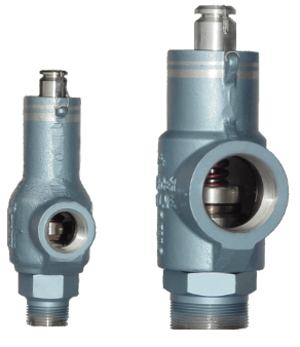

Manual for Mercer Valve Pressure Relief Valve 81-11151B18G21

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Mercer Valve Pressure Relief Valve 81-11151B18G21

Create an account to install this asset package.

Maintenance Plans for Mercer Valve Pressure Relief Valve Model 81-11151B18G21

Integrate maintenance plans directly into your work orders in MaintainX.

1 Monthly Gauge Calibration

Warning: This procedure requires trained personnel!

Are two pressure gauges used for testing?

Are the gauges reading identical values within their respective tolerances?

Select the type of the first gauge

Select the type of the second gauge

Is at least one of the gauges an analog (dial) gauge that is not liquid filled?

Is the second gauge a digital gauge?

Does the test gauge have at least 0.25% accuracy over their full scale?

Is the portion of the gauge used selected so that the tolerance of it is more stringent than the set pressure's tolerance?

1 Yearly Pressure Relief Valve Set Pressure Inspection

During the set pressure inspection, the set pressure is verified in accordance with the ASME BPVC.

For all valves set 70psi (500kPa) and above, the set pressure has a tolerance of $3% of the set pressure.

For all set pressure below 70psi (500kPa) the tolerance is (±2psi ((±15kPa).

If the valve has a CDTP associated with it due to temperature and/or backpressure, the test pressure is checked to the CDTP.; Even with a CDTP the set pressure tolerance is calculated based on the actual nameplate set pressure.; The set pressure test should be performed before and after any repairs.

The set pressure is inspected to the definition listed in NB-18, a publication by the National Board of Pressure Vessel Inspectors, which is found at http://www.nationalboard.org/.

This publication lists all ASME BPVC certified pressure relief valves.

It indicates the correct set pressure definition and other characteristics of a valve.; The set pressure has been defined to achieve a particular operational characteristics.; If the wrong set pressure definition is used in the inspection test, the valve's set pressure will not be accurate and it may not operate appropriately.

The correct fluid for testing has to be used to achieve accurate results.; For gas/vapor service, nitrogen or compressed air is used as the test fluid, while for liquid service, water is used.; If the incorrect fluid is used during the testing, the test's results will be inaccurate.; Depending on the size of the valve and its set pressure, the set pressure discrepancy can vary outside of ASME tolerances.

Setting procedures should be in accordance with ASME PTC 25.; The rate of the system pressure increase should be slow when the pressure is within 15% of the set pressure. Within this range, the rate should never be more than 2psi/sec (15kPa/sec).; Ideally each pressure increment on the pressure gauge should be clearly read as the pressure is increased. Slow pressure increase helps to accurately read the pressure gauge.

1 Yearly Pressure Relief Valve Leak Inspection

Warning: This inspection requires trained personnel with PPE!

Enter the set pressure of the valve

Enter the leak test pressure

Contact Mercer Valve Co. Inc. for proper leak pressure and specification for the valve.

Did the pressure hold steady during the test?

If the pressure did not hold steady, there is a potential leak and the valve should be removed for further testing.

Did the valve pass the API STD 527 test?

For soft seated valves, such as the 8100 Series, zero bubbles are observed for one minute to pass leak inspection per API 527.

Did the valve pass the soap film test?

Pressure Relief Valve Offsite Testing

Warning: This procedure requires trained personnel with PPE!

Is the valve removed from the unit?

If the valve is not removed, stop the procedure and report to the supervisor

Enter the volume of pressure

Enter the valve simmer

Enter the pressure losses to the gauges

Enter the supply line pressure

Is the test bench properly assembled?

If the test bench is not properly assembled, stop the procedure and report to the supervisor

Pressure Relief Valve Component Inspection

Warning: This inspection requires trained personnel with PPE!

Inspect the seat for cuts and abrasions

Polish the seat area lightly with a fine grade abrasive pad

Replace the seat if it is damaged with deep abrasions and cuts

Measure the diameter Ds of the nozzle

Inspect the disk subassembly

Polish the spherical surface with a fine grade abrasive if only minor imperfections exist

Replace the disk if the spherical surface is damaged or scratched

Measure the diameter Da

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX