The Lincoln Electric Welder WM-250 is a robust industrial welding machine designed for high-performance applications. Known for its reliability and efficiency, this welder is ideal for both professional and heavy-duty use, ensuring optimal welding results across various materials and thicknesses.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Welder WM-250

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Welder WM-250

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Welder Model WM-250

Integrate maintenance plans directly into your work orders in MaintainX.

Drive Rolls and Guide Tubes Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Wire drive mechanism inspected after every coil of wire?

Wire drive mechanism cleaned with low pressure compressed air?

Did you use solvents for cleaning the idle roll?

If solvents were used, report to the maintenance team and stop the procedure

Drive rolls stamped with the wire sizes they will feed?

Choose the wire size used

Sign off on the drive rolls and guide tubes maintenance

Welder Maintenance

Inspect the mating surfaces of the spindle hubs and the spindle mounting clips (V-brackets) and, if necessary, wipe or blow out any dirt and debris which may have accumulated on these surfaces

Replace worn contact tips as required

Remove spatter from the inside of the gas nozzle and tip every 10 minutes of arc time or as required

Choose the correct size contact tip for the electrode being used

Be sure the nozzle insulator is fully screwed onto the gun tube and does not block the gas holes in the diffuser

Slip or screw the appropriate gas nozzle onto the nozzle insulator

Select the gas nozzle based on the welding application

Adjust the gas nozzle as appropriate for the GMAW process to be used

Set the contact tip end

1 Daily Welder Maintenance

No combustible materials in the welding or cutting area or around the machine

No debris, dust, dirt, or materials that could block the air flow to the machine

Electrode cables free of any slits, punctures in the cable jacket, or any condition that would affect the proper operation of the machine

Sign off on the daily welder maintenance

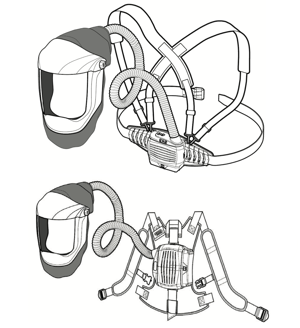

Gun Handle Assembly Inspection

Warning: This inspection requires trained personnel with PPE!

Internal parts of the gun handle inspected

Gun handle consists of two halves held together with a collar on each end

Turn the collars approximately 60 degrees counterclockwise

Collar reaches a stop

Collar pulled off the gun handle

NOTE: If the collars are difficult to turn, position the gun handle against a corner, place a screwdriver against the tab on the collar and give the screwdriver a sharp blow to turn the collar past an internal locking rib

Sign off on the gun handle assembly inspection

Cable Cleaning

Cable removed from the wire feeder and laid out straight on the floor

Contact tip removed from the gun

Low pressure air used to gently blow out the cable liner from the gas diffuser end

Cable flexed over its entire length and blown out again

Procedure repeated until no more dirt comes out

Sign off on the cable cleaning

Parts for Lincoln Electric Welder WM-250

Access the parts list for your equipment in MaintainX.

Contact Tips

S19391-7

Contact Tips

S19392-1

Contact Tips

S19391-1

Contact Tips

S19292-2

Adjustable Slip-On

M16093-1

Contact Tips

S19391-7

Contact Tips

S19392-1

Contact Tips

S19391-1

Contact Tips

S19292-2

Adjustable Slip-On

M16093-1

Contact Tips

S19391-7

Contact Tips

S19392-1

Contact Tips

S19391-1

Contact Tips

S19292-2

Adjustable Slip-On

M16093-1

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX