The Lincoln Electric Welder K3425-1 is a robust industrial welding machine designed for high-performance applications. Known for its reliability and efficiency, this welder is ideal for both professional and DIY projects, ensuring quality welds with ease of use.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Welder K3425-1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Welder K3425-1

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Welder Model K3425-1

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Welder Cleaning

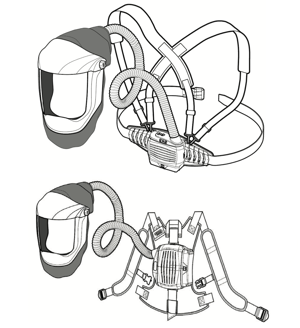

Warning: This cleaning procedure requires trained personnel with PPE!

Machine cleaned with a low pressure airstream?

Select all parts that have been cleaned

Machine operating cooler and with higher reliability after cleaning?

Sign off on the welder cleaning

Welder Voltage Calibration

Connect a resistive load bank to the machine configured for 300A/20V (750A/50V equivalent)

Connect a certified calibrated voltmeter to the output circuit. Use the M25303 low pass filter supplied with the K4171-1 Power Wave Calibration Kit between the meter and the power source

Disconnect input power from the machine being calibrated and remove the right case side to provide access to the User Interface

Rotate the Hot Start control and Arc Control knobs completely counter-clockwise

Replace the right case side; reconnect input power to the machine and energize. The display should read “Cur CAL”

Rotate the Arc Control knob until the display reads “VoL CAL”

Rotate the Hot Start knob clockwise to enable the output which will be indicated by the scrolling message “AdJ Pot So rEAL VoL = 20 VoL” on the display

Enter the actual output voltage

Adjust the output control knob until the actual output voltage reading is within the specified range (20 +/- 0.5 V)

Welder Current Calibration

Connect a resistive load bank to the machine configured for 300A/20V (750A/50V equivalent)

Connect a certified calibrated current probe or current meter and shunt to the output circuit

Disconnect input power from the machine being calibrated remove the right case side to provide access to the User Interface

Rotate the Hot Start control and Arc Control knobs completely counter-clockwise

Replace the right case side; reconnect input power to the machine and energize

The display should read “Cur CAL”

Rotate the Hot Start knob clockwise to enable the output which will be indicated by the scrolling message “AdJ Pot So rEAL Cur = 300 A” on the display

The actual output current should be 300 +/- 2 A

Adjust the output control knob until the actual output current reading is within the specified range

Welder Routine Maintenance

Examine the sheet metal case for dents or breakage

Repair the case as required

Keep the case in good condition to insure that high voltage parts are protected and correct spacings are maintained

All external sheet metal screws must be in place to insure case strength and electrical ground continuity

Sign off on the welder routine maintenance

Welder Visual Inspection

Clean interior of machine with a low pressure air stream

Make a thorough inspection of all components

Look for signs of overheating, broken leads or other obvious problems

Many problems can be uncovered with a good visual inspection

Upload a photo of the machine after inspection

Sign off on the visual inspection

Parts for Lincoln Electric Welder K3425-1

Access the parts list for your equipment in MaintainX.

#10-24X.50HHCS-FULL-GR2-3147

9SCF000371

Self Tapping Screw

9SS9225-100

Output Stud Cover

9SG6864

Washer

9SS9262-184

UI Board Assembly

9SS32071-1

#10-24X.50HHCS-FULL-GR2-3147

9SCF000371

Self Tapping Screw

9SS9225-100

Output Stud Cover

9SG6864

Washer

9SS9262-184

UI Board Assembly

9SS32071-1

#10-24X.50HHCS-FULL-GR2-3147

9SCF000371

Self Tapping Screw

9SS9225-100

Output Stud Cover

9SG6864

Washer

9SS9262-184

UI Board Assembly

9SS32071-1

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX