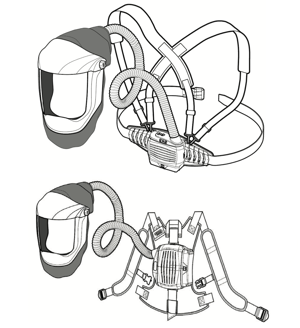

The Lincoln Electric Double Header DH-10 is a robust industrial welding machine designed for high-performance applications. Known for its reliability and efficiency, this model excels in delivering quality welds while minimizing downtime through effective maintenance strategies. Ideal for various welding tasks, it ensures optimal productivity in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Double Header DH-10

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Double Header DH-10

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Double Header Model DH-10

Integrate maintenance plans directly into your work orders in MaintainX.

Drive Rolls and Guide Tubes Maintenance

Drive roll section inspected after feeding every coil of wire

Drive roll section cleaned as necessary

Was solvent used for cleaning the idle roll?

Warning: Do not use a solvent for cleaning the idle roll because it may wash the lubricant out of the bearing

Drive roll and guide tubes stamped with the wire sizes they will feed

Roll(s) and guide tubes changed if a wire size other than that stamped on the roll(s) is to be used

Drive rolls for .035” (0.9mm) through .052” (1.3mm) cored electrode and 1/16” (1.6mm) through 3/32” (2.4mm) electrode have a double set of teeth so they can be reversed for additional life

Drive rolls for .023\ (0.6 mm) through .052\" (1.3 mm) solid electrodes and aluminum sizes have no teeth

Sign off on the drive rolls and guide tubes maintenance

1 Yearly Wire Drive Motor and Gearbox Maintenance

Gearbox inspection

Type of grease used for gear teeth

Warning: Do not use graphite grease

Enter the length of the motor brushes in mm

Motor brushes replaced if less than 6.4mm long

Sign off on the motor and gearbox maintenance

Parts for Lincoln Electric Double Header DH-10

Access the parts list for your equipment in MaintainX.

Cored Electrode

KP1505 - 045C

Solid Steel Electrode

KP1505 - 052S

Aluminum Electrode

KP1507 - 040A

Solid Steel Electrode

KP1505 - 045S

Cored Electrode

KP1505 - 3/32

Cored Electrode

KP1505 - 045C

Solid Steel Electrode

KP1505 - 052S

Aluminum Electrode

KP1507 - 040A

Solid Steel Electrode

KP1505 - 045S

Cored Electrode

KP1505 - 3/32

Cored Electrode

KP1505 - 045C

Solid Steel Electrode

KP1505 - 052S

Aluminum Electrode

KP1507 - 040A

Solid Steel Electrode

KP1505 - 045S

Cored Electrode

KP1505 - 3/32

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX